A plastic mold for the production of plastic rings

A plastic mold and plastic technology, applied in the field of plastic molds, can solve the problems of not being able to squeeze it, cool it, increase the density of the plastic ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

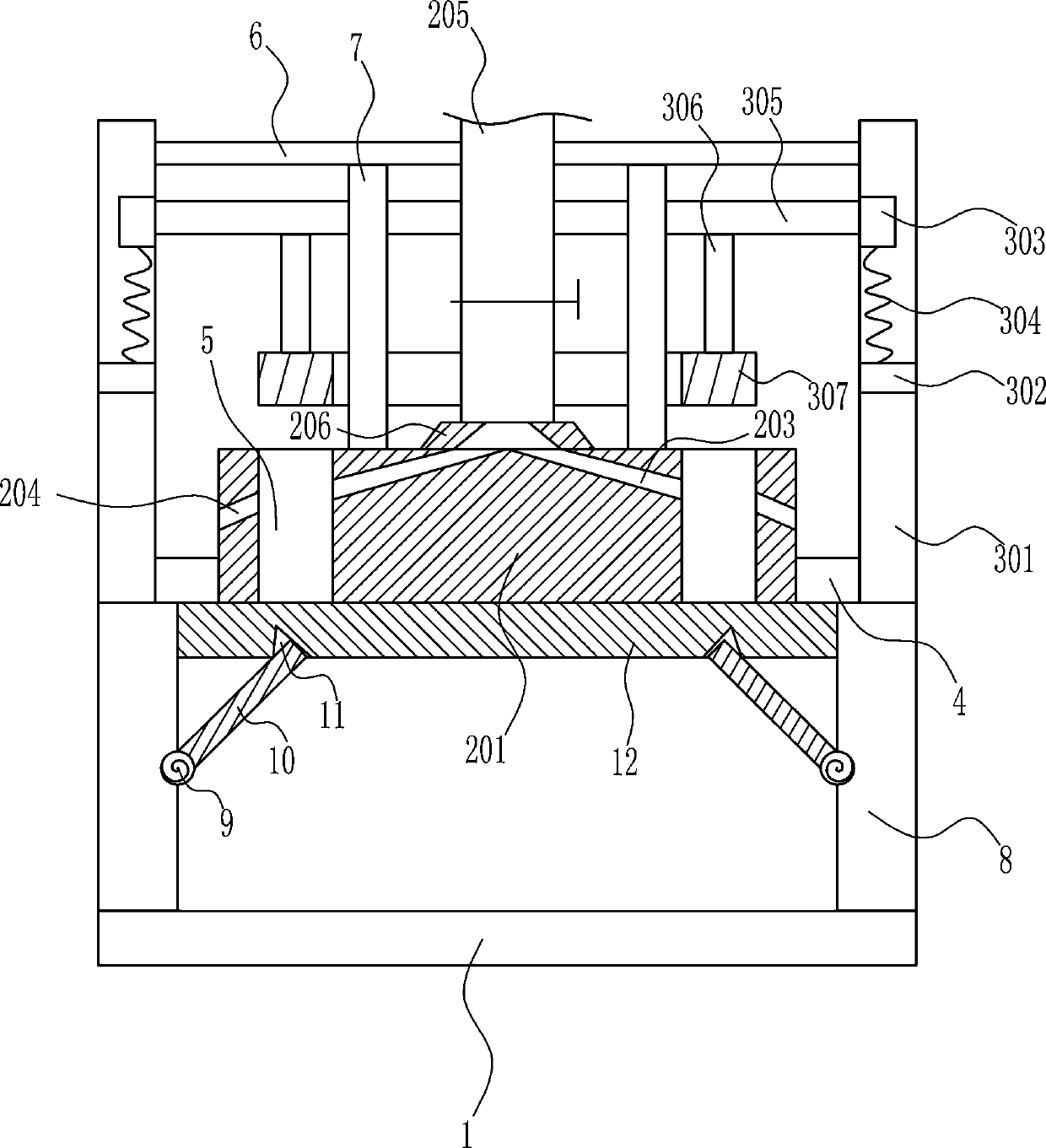

[0037] A plastic mold for the production of plastic rings, such as Figure 1-7 As shown, it includes a bottom plate 1 , a forming mechanism 2 and a compacting mechanism 3 , the top of the bottom plate 1 is connected with the forming mechanism 2 , and the top of the bottom plate 1 is connected with the compacting mechanism 3 .

Embodiment 2

[0039] A plastic mold for the production of plastic rings, such as Figure 1-7 As shown, it includes a bottom plate 1 , a forming mechanism 2 and a compacting mechanism 3 , the top of the bottom plate 1 is connected with the forming mechanism 2 , and the top of the bottom plate 1 is connected with the compacting mechanism 3 .

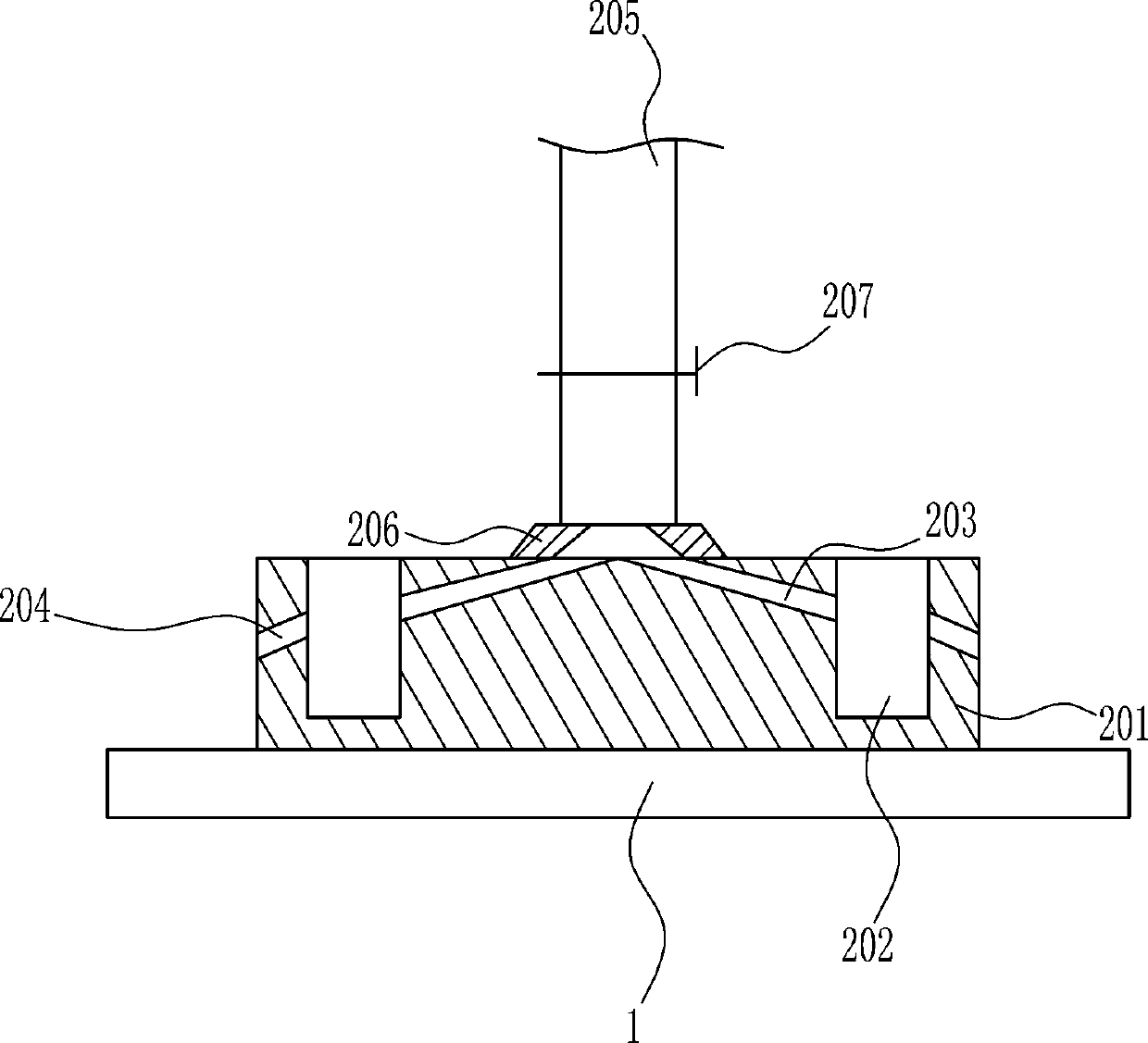

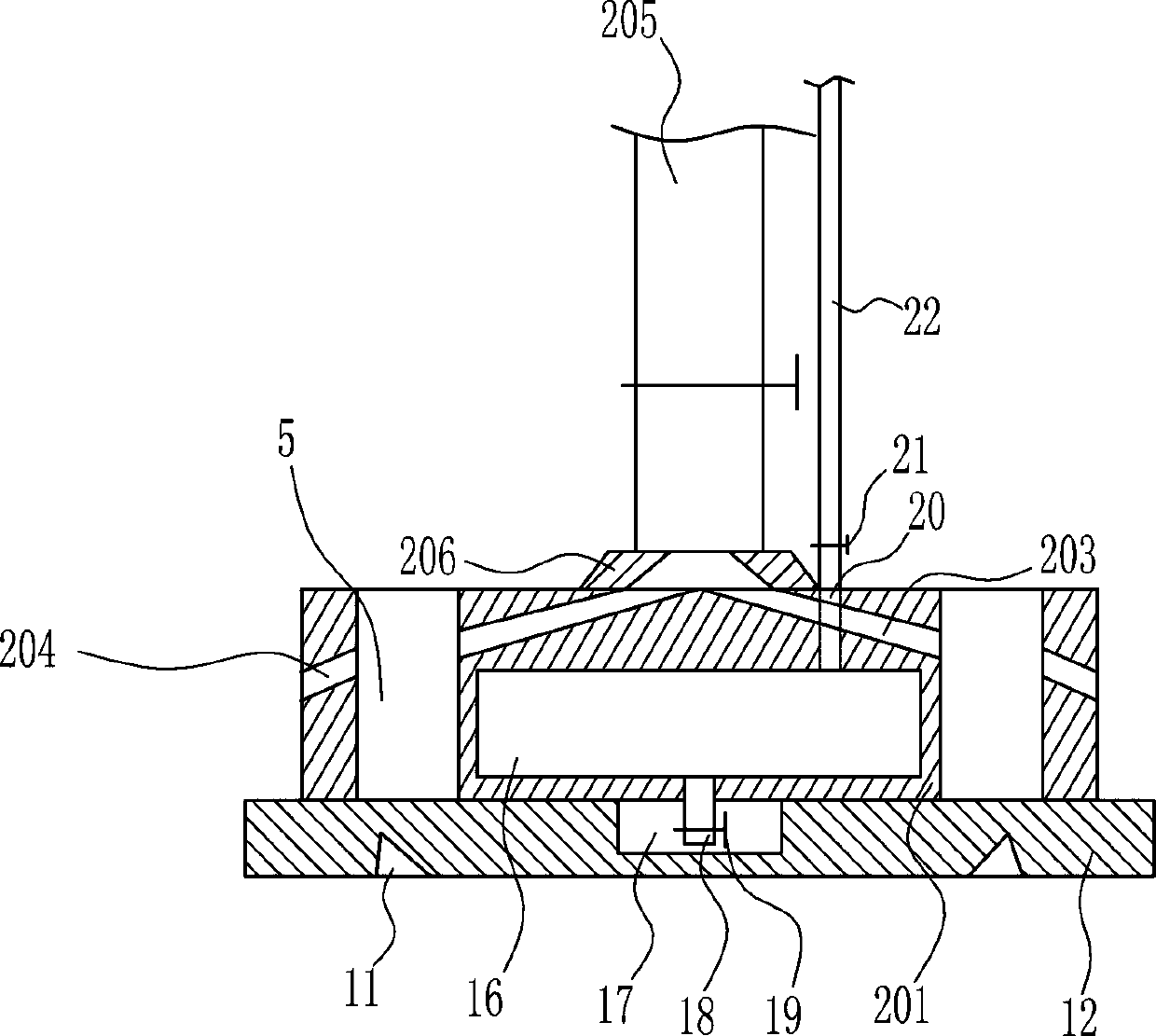

[0040] The forming mechanism 2 includes a bottom mold 201, a feed pipe 205, a first connecting block 206 and a first valve 207. The top of the bottom plate 1 is connected with a bottom mold 201, and the top of the bottom mold 201 is provided with an annular groove 202. The upper side of the bottom mold 201 There are first through holes 203 symmetrically left and right, second through holes 204 are opened on the left and right sides of the bottom mold 201, the second through holes 204 on the left and right sides are lower than the first through holes 203, and the top of the bottom mold 201 is connected with the first The connection block 206 , the top of...

Embodiment 3

[0042] A plastic mold for the production of plastic rings, such as Figure 1-7 As shown, it includes a bottom plate 1 , a forming mechanism 2 and a compacting mechanism 3 , the top of the bottom plate 1 is connected with the forming mechanism 2 , and the top of the bottom plate 1 is connected with the compacting mechanism 3 .

[0043] The forming mechanism 2 includes a bottom mold 201, a feed pipe 205, a first connecting block 206 and a first valve 207. The top of the bottom plate 1 is connected with a bottom mold 201, and the top of the bottom mold 201 is provided with an annular groove 202. The upper side of the bottom mold 201 There are first through holes 203 symmetrically left and right, second through holes 204 are opened on the left and right sides of the bottom mold 201, the second through holes 204 on the left and right sides are lower than the first through holes 203, and the top of the bottom mold 201 is connected with the first The connection block 206 , the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com