Plastic pipe hot melt connection device

A technology of connecting device and plastic pipe, applied in the field of plastic processing machinery, can solve the problems of high labor cost, large power consumption, large odor, etc., and achieve the effect of firm connection, tight connection and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

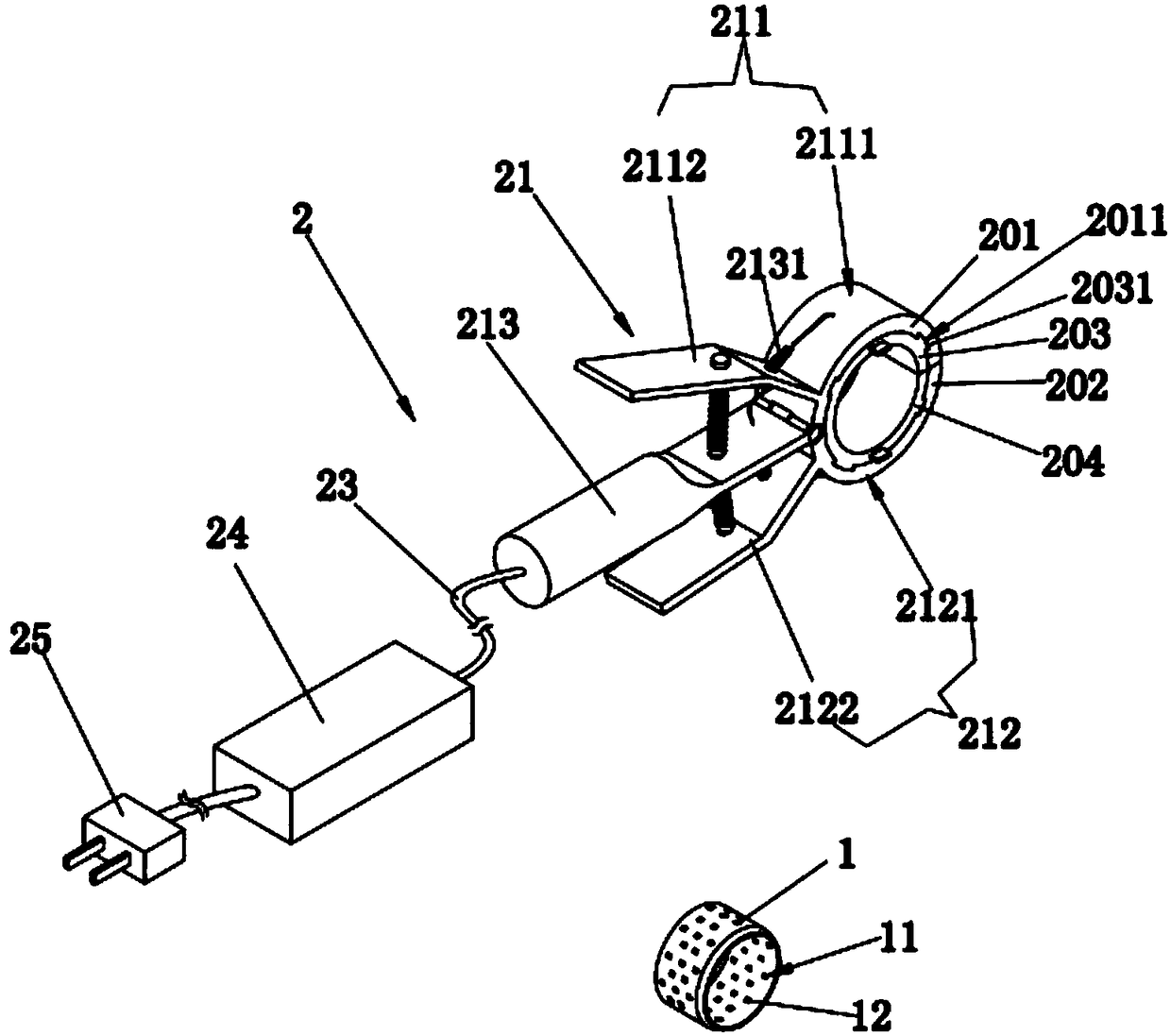

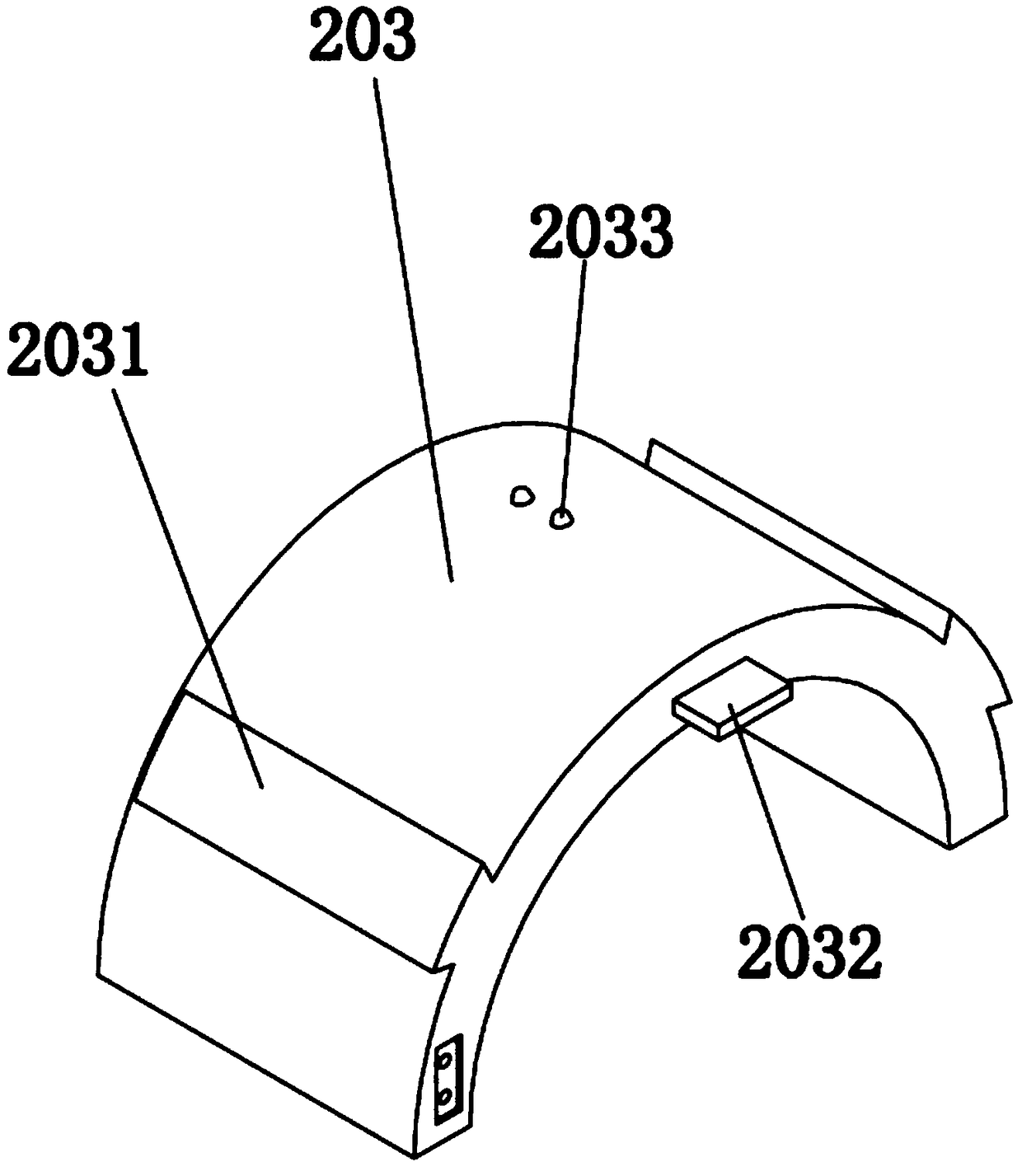

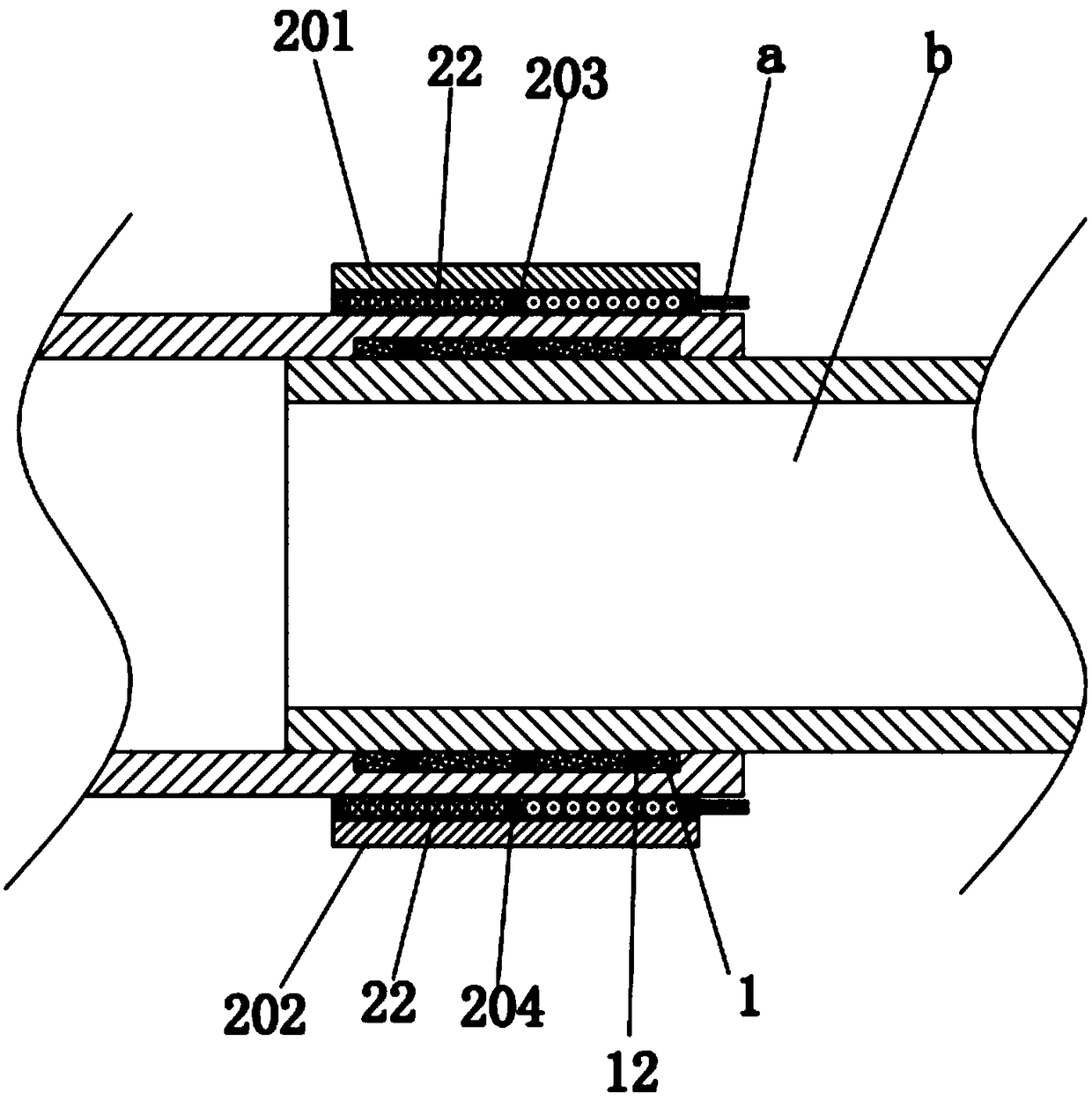

[0024] The reference signs in the drawings of the description include: plastic pipe joint a, plastic pipe b, liner c, round pipe 1, through hole 11, plastic 12, heater 2, clamp 21, upper splint 211, clamping part 2111, Operating part 2112, outer plate 201, tongue and groove 2011 outer plate 202, inner plate 203, elastic contact rod 2031, boss 2032, socket 2033, inner plate 204, inner plate 203, lower splint 212, clip Holding part 2121, operating part 2122, electromagnetic heating controller 213, plug 2131, heating coil 22, wire 23, adapter 24, plug 25.

[0025] refer to figure 1 and image 3 , a hot-melt connection device for plastic pipes, a liner c set between a plastic pipe joint a and a plastic pipe b and a heater 2 for heating the liner c. Wherein the lining c is an iron-containing product, the heater 2 includes a fixture 21, and a heating coil 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com