Cement bag opening folding device

A technology of cement bags and bag-opening boards, which is applied in packaging, bag making operations, transportation and packaging, etc., can solve the problems of high cost, large amount of cylinder assembly, and large energy consumption, and achieve cost reduction, reduce assembly amount, and improve The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

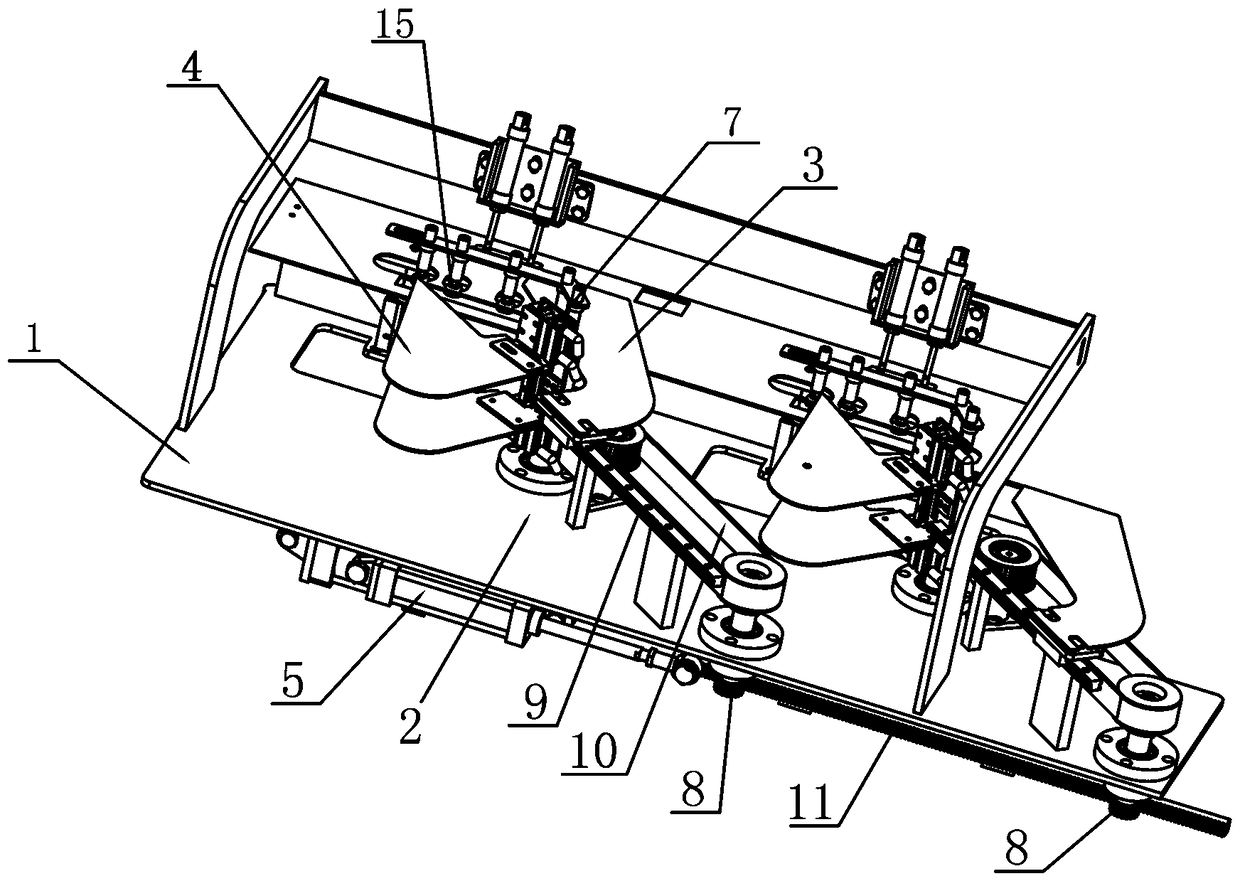

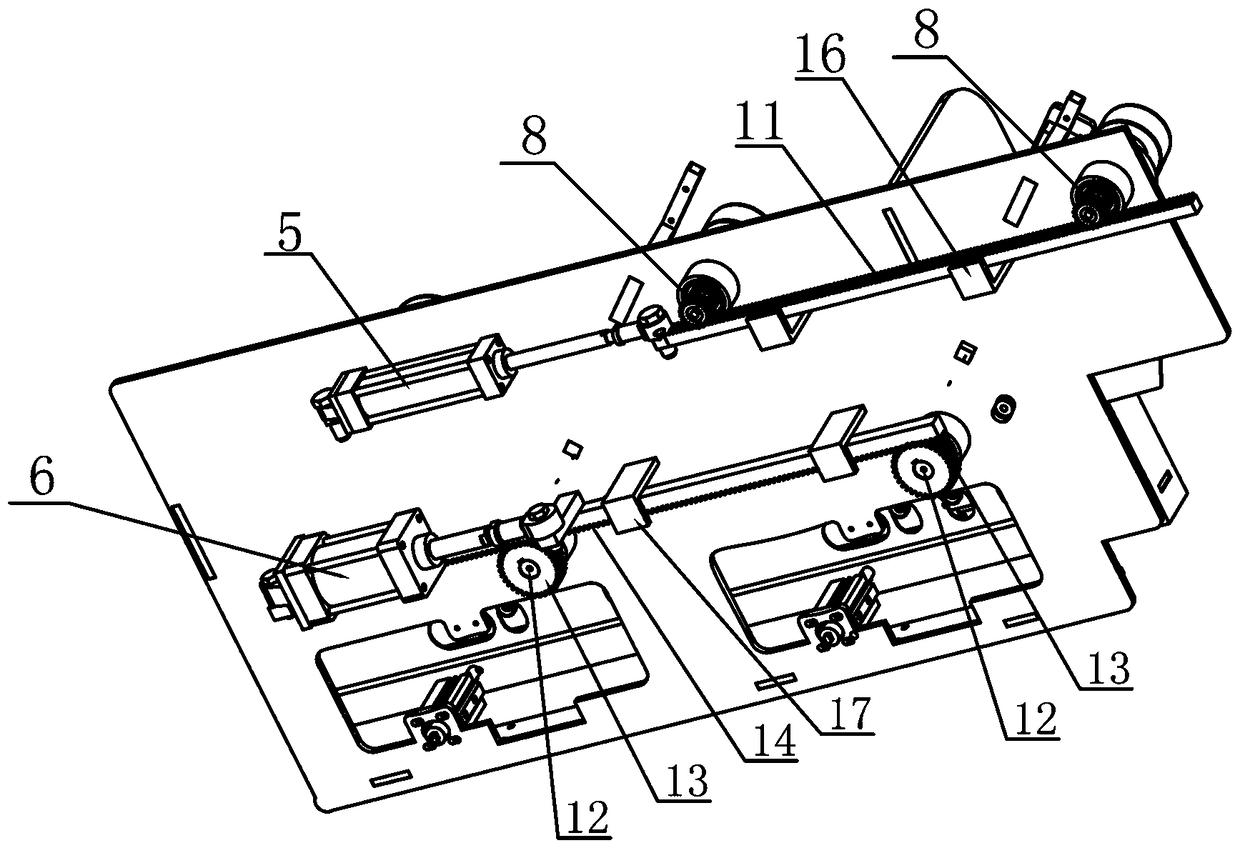

[0015] With reference to the accompanying drawings, the cement bag folding device includes a frame 1, at least two groups of folding units are successively arranged on the bag conveying path of the frame, and the folding unit 2 includes a bag opening mechanism and a corner folding mechanism, and the frame 1 is provided with a group of synchronous transmission mechanism A and a group of synchronous transmission mechanism B, the angled mechanism includes the angled plate 3, and the synchronous transmission mechanism A simultaneously drives the angled plates 3 of each group to perform reciprocating linear motion, and the bag opening mechanism Including the bag opening plate 4, the rotating shaft 12 and the bag opening power source 7, the synchronous transmission mechanism B simultaneously drives each group of bag opening plates 4 to rotate around the rotating shaft 12, and the bag opening power source 7 drives the bag opening plate 4 to move up and down Bag opening movement, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com