Basic storage device for valve production line

A production line and basic technology, used in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of different production rhythms and the production efficiency of production lines cannot be guaranteed, and achieve the effect of improving stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

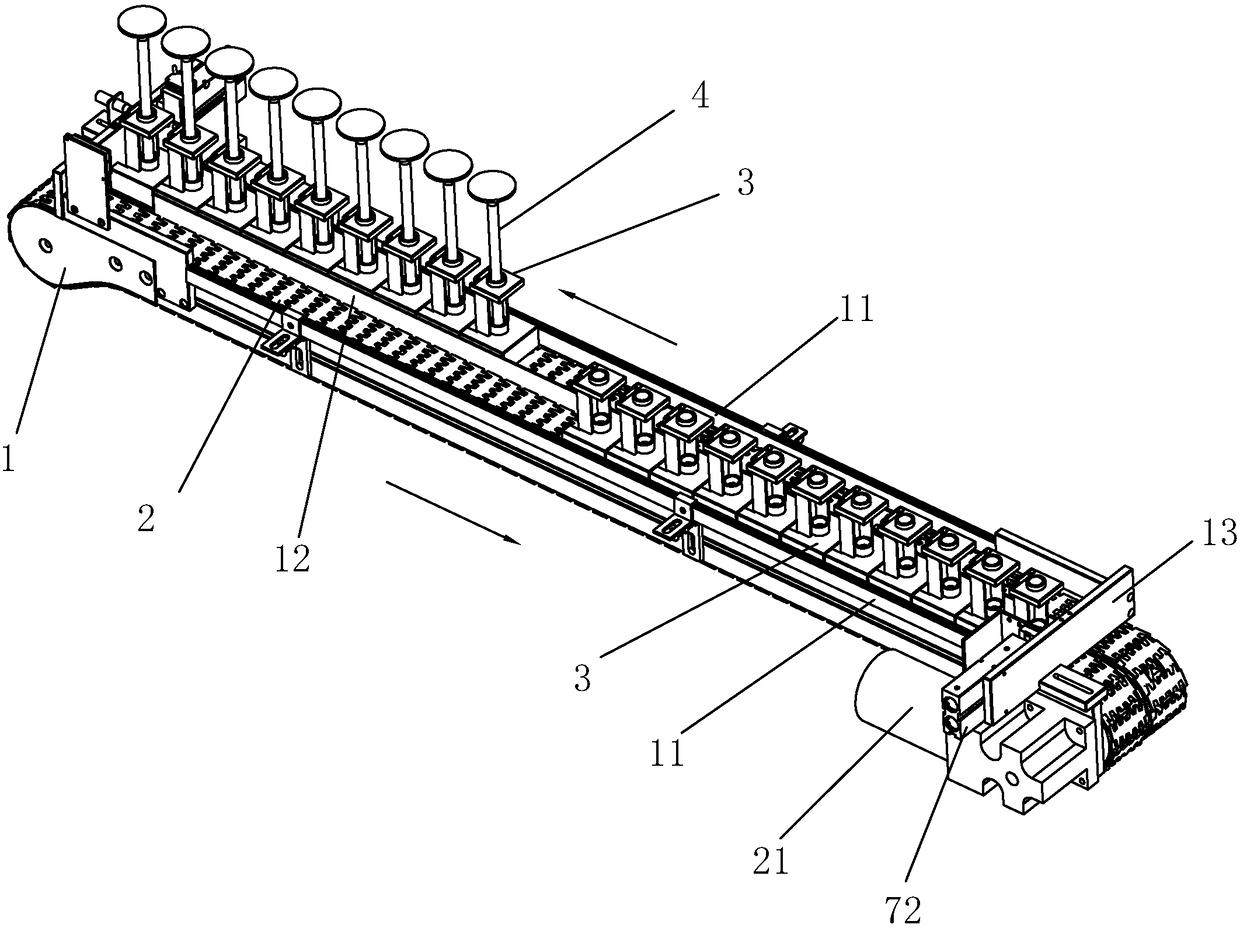

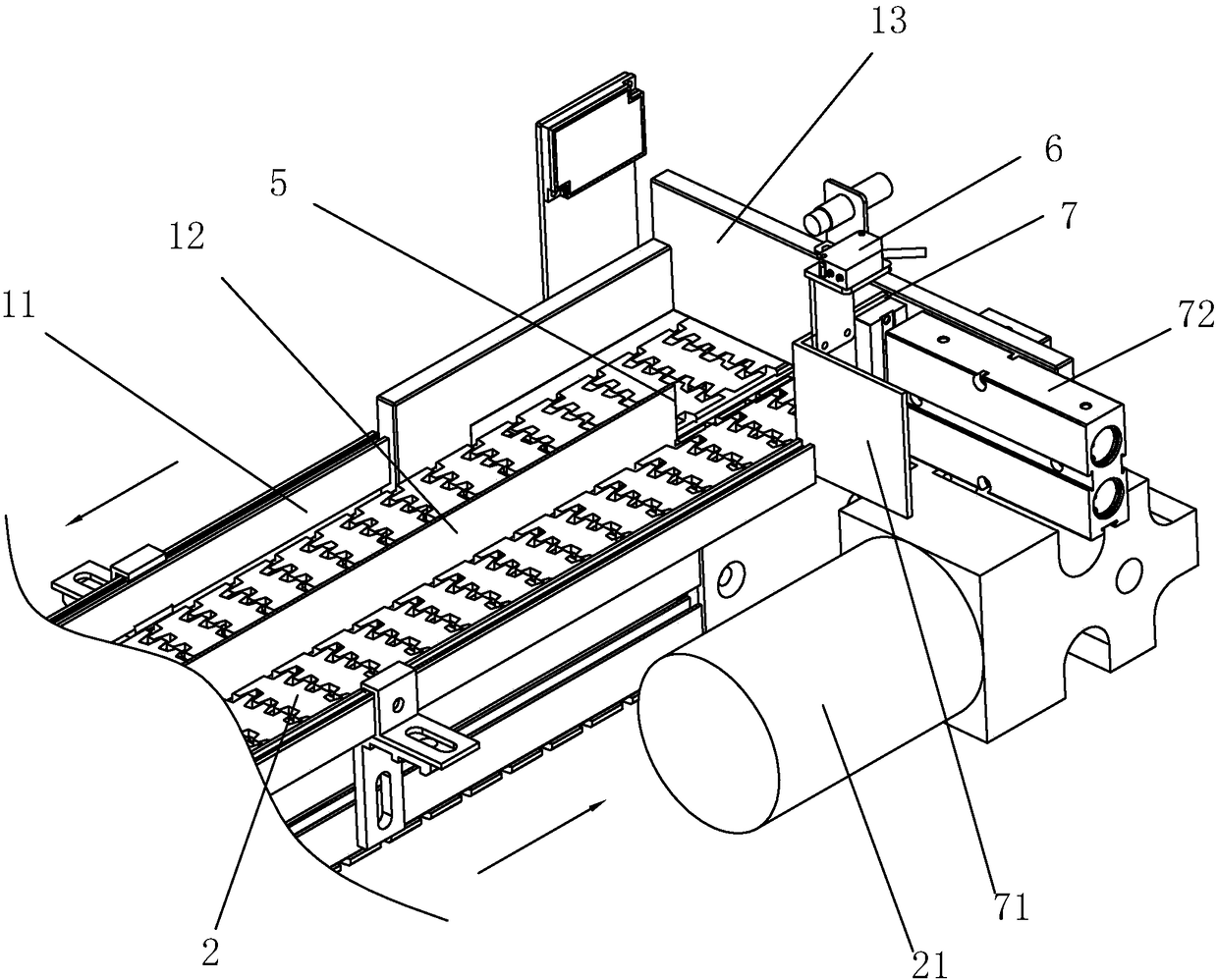

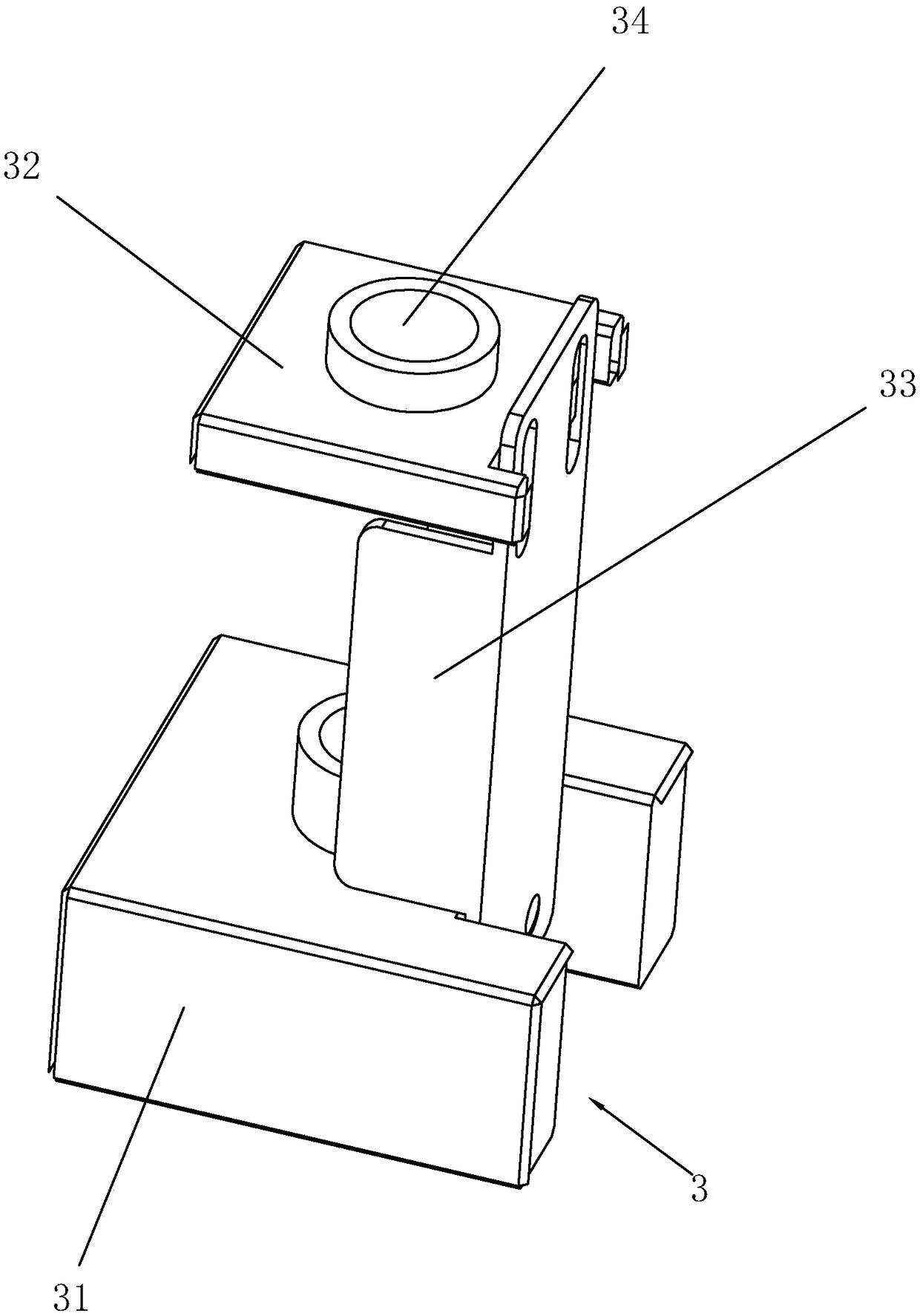

[0017] The following is attached Figure 1-3 The present invention is described in further detail.

[0018] A basic material storage device for a valve production line, including a frame 1 arranged between adjacent equipment, two conveyor belts 2 are arranged side by side on the frame 1, and the two ends of the conveyor belt 2 face the upstream equipment and the downstream equipment respectively . The transmission directions of the two conveyor belts 2 are opposite. In this embodiment, the conveyor belt 2 is a chain plate, and the two ends of the conveyor belt 2 on the frame 1 are respectively provided with servo motors 21, and the two servo motors 21 are located on the frame. 1 on both sides, drive the conveyor belt 2 to slide. Between two conveyer belts 2, be provided with dividing plate 12, dividing plate 12 is provided with along the length direction of conveyer belt 2, is provided with guardrail 11 on both sides of two conveyer belts 2, at the two ends of two conveyer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com