Crane traveling axis cable climbing fixing rack

A technology of fixing frame and axis, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of broken cables, easy shaking, and no protection of cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

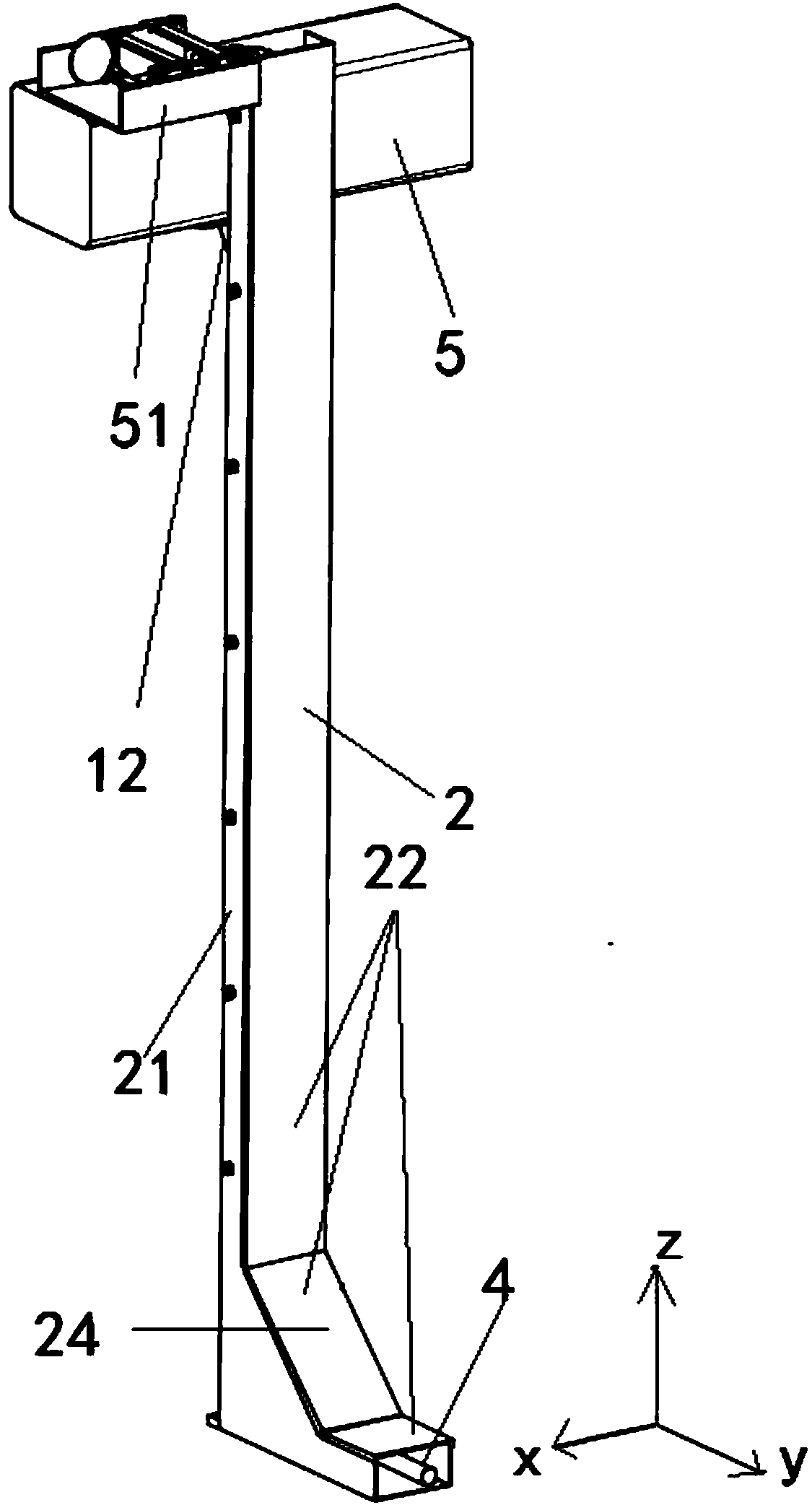

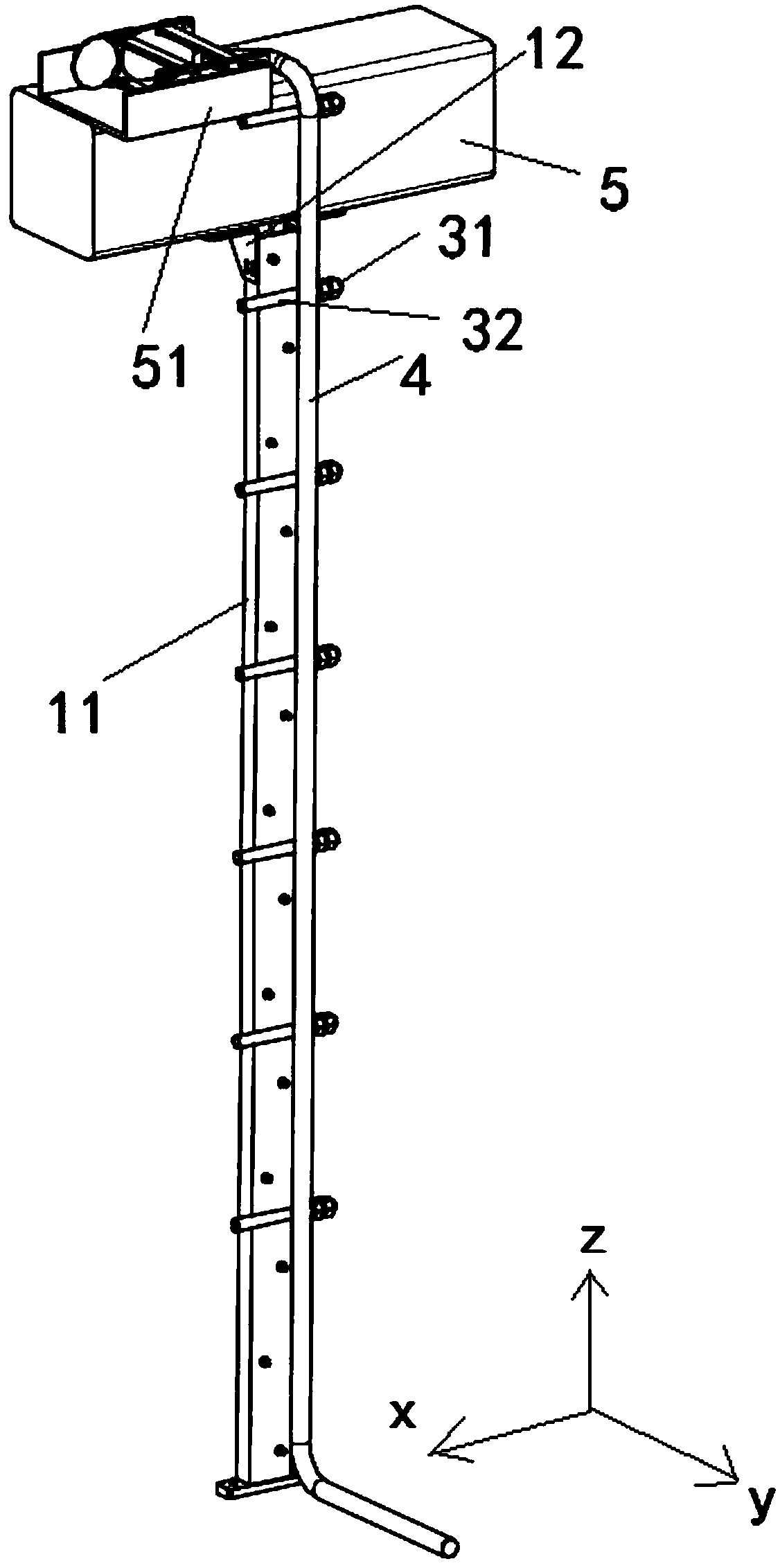

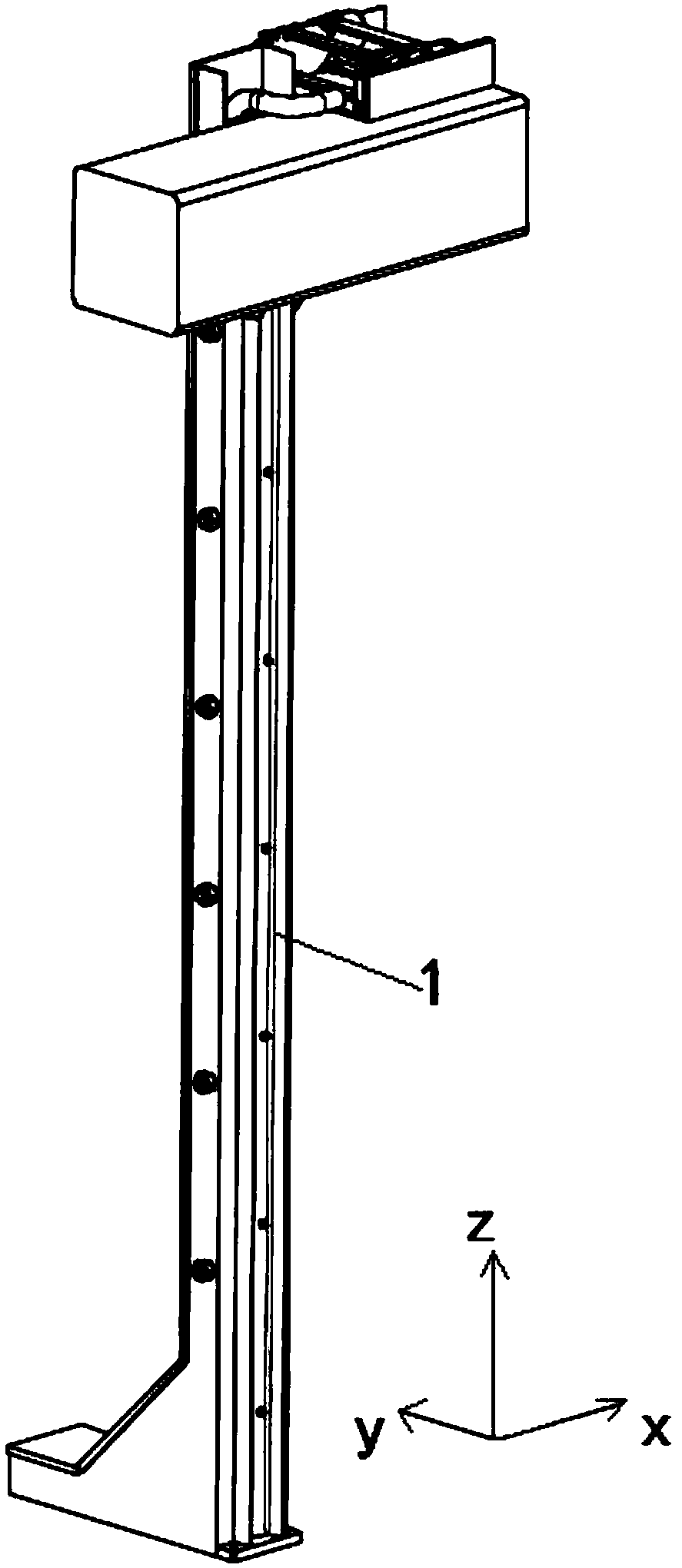

[0025] figure 1 It is a perspective view of a climbing fixed frame of a sky crane traveling shaft cable of the present invention; figure 2 It is a perspective view of an angled perspective view of the cable climbing fixing frame of the overhead traveling axle cable of the present invention without the trunking shell; image 3 It is a perspective view from another angle of the overhead crane traveling shaft cable climbing fixing frame of the present invention without the trunking shell; Figure 4 It is a side view of the climbing fixed frame of a sky crane traveling shaft cable of the present invention; Figure 5 It is a schematic diagram of the cable fixing part of the overhead crane traveling shaft cable climbing fixing frame of the present invention; Image 6 It is a rear view of the climbing fixed frame of a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap