Glass-fiber-reinforced high-flame-retardance PC/PBT composite material for new-energy automobile and preparation method for glass-fiber-reinforced high-flame-retardance PC/PBT composite material

A technology of new energy vehicles and composite materials, which is applied in the field of polymer modification and processing, can solve the problems of large gaps in flame retardancy, achieve high flame retardancy, balance performance between rigidity and toughness, and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

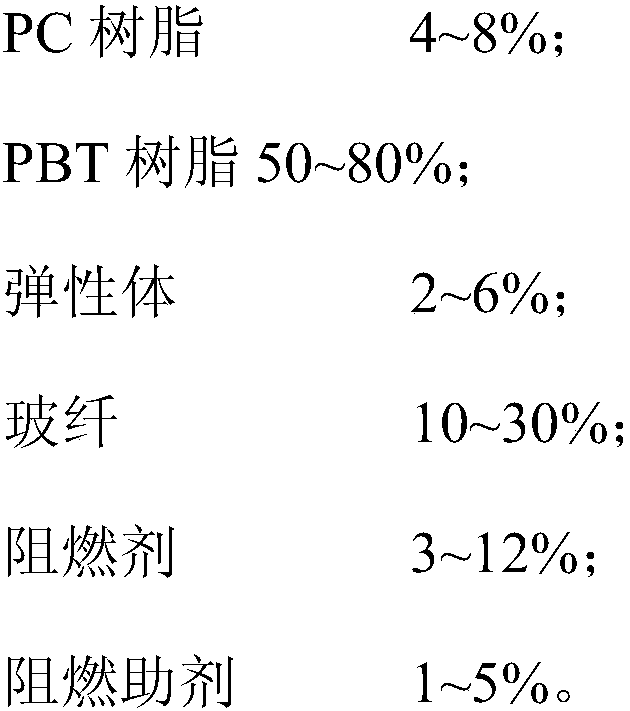

Method used

Image

Examples

Embodiment Construction

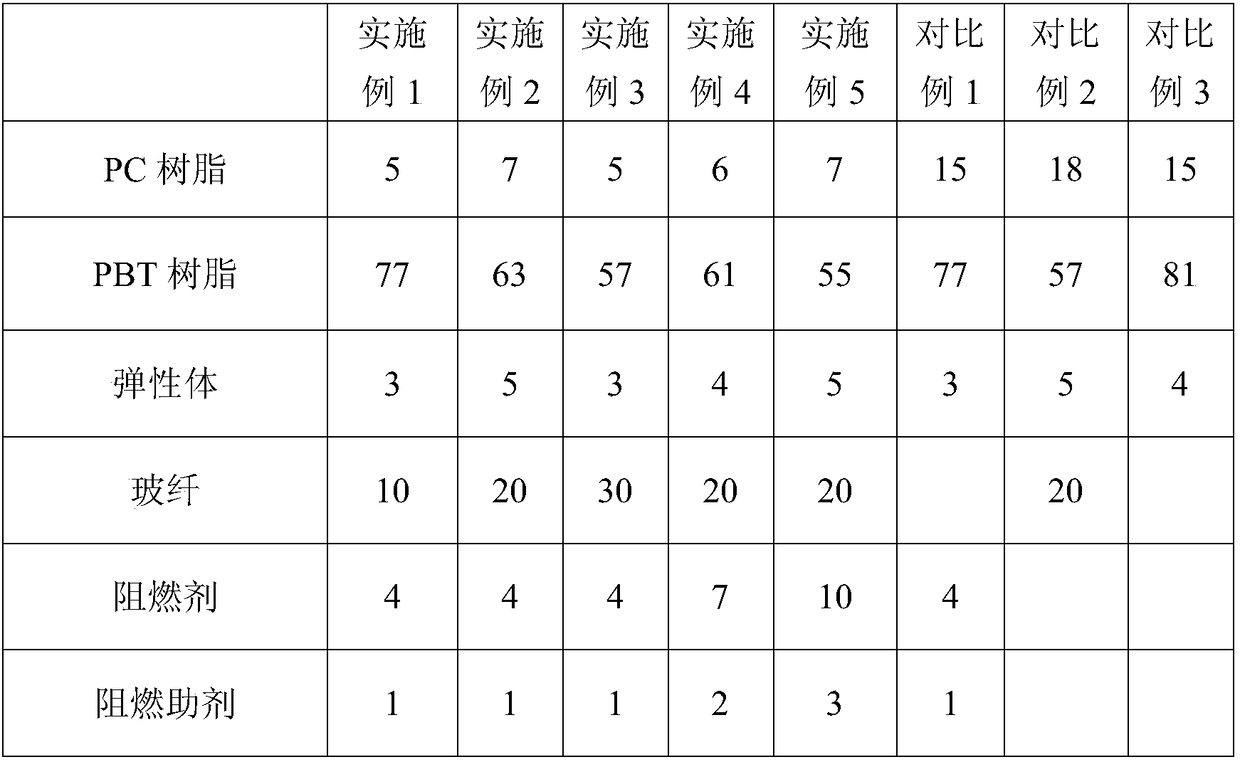

[0019] The present invention will be further described below through specific examples, but the examples are only used to illustrate the present invention rather than limit the present invention.

[0020] Raw materials used in the embodiments of the present invention:

[0021] PC resin: bisphenol A resin type resin with a molecular weight of 24000-27000, Samsung Petrochemical Company of South Korea.

[0022] PBT resin: PBT-4500, BASF Corporation.

[0023] Elastomer: Elastomer-PTW, DuPont.

[0024] Glass fiber: glass fiber 303H, China Jushi Company.

[0025] Flame retardant: brominated epoxy resin F-3100, Guangzhou Qingniao Chemical Co., Ltd.

[0026] Flame retardant additive: antimony trioxide, Guangzhou Qingniao Chemical Co., Ltd.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap