Polypropylene material for transparent bottles and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of polypropylene material and preparation for transparent bottles, can solve the problems such as the inability to achieve transparency, the transparency requirements of nursing bottles and sports water bottles, etc., and achieve improved transparency, high melt flow rate, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: the preparation method of base resin:

[0028] 1. The raw materials for the production of base resin are the following substances:

[0029] 1) Polymer grade propylene

[0030] project

Purity %

Water content 10-6

CO content 10-6

CO 2 Content 10-6

indicators

≥99.35

≤5

≤0.2

≤4

[0031] 2) Polymer grade ethylene

[0032] project

Purity %

Water content 10-6

CO content 10-6

CO 2 Content 10-6

indicators

≥99.92

≤3

≤0.03

≤3

[0033] 3) Based on the production of one ton of random polypropylene, add the following reagents: 35kg / ton catalyst DQ-III, 0.18kg / ton cocatalyst TEAL, 0.04kg / ton electron donor DONOR, 0.11kg / ton antistatic agent Atmer163.

[0034] 4), hydrogen

[0035] project

Purity %

Water content 10-6

CO content 10-6

Total sulfur content 10-6

indicators

≥95...

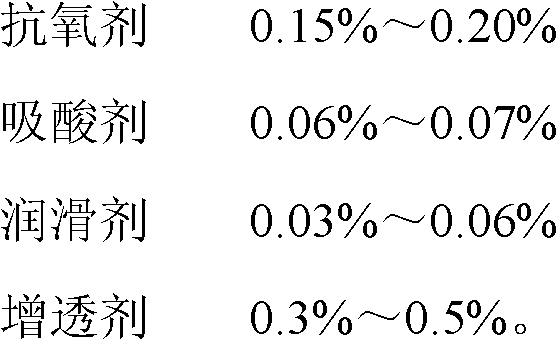

Embodiment 2

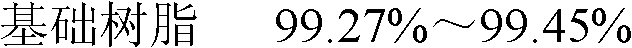

[0041] Add 99.45% (mass percentage) of random copolymer polypropylene base material into the 10.0L mixer according to the formula, add 0.3% (mass percentage) of anti-reflection agent NX8000K, 0.15% (mass percentage) of antioxidant, and 0.07% of acid absorbing agent (mass percentage), lubricant 0.03% (mass percentage), after 2min of high-speed mixing at normal temperature and pressure in the high-speed mixer, extrude granulation at 160 ℃ in the twin-screw granulator, by sampling analysis, haze reaches 11.8 % to obtain polypropylene for transparent bottles.

Embodiment 3

[0043]Add 99.40% (mass percentage) of random copolymer base material to the 10.0L mixer according to the formula, add 0.35% (mass percentage) of anti-reflection agent NX8000K, 0.15% (mass percentage) of antioxidant, and 0.07% acid absorbing agent (mass percentage), lubricant 0.03% (mass percentage), after high-speed mixing 3min in high-speed mixer, extrude granulation at 250 ℃ in twin-screw granulator, by sampling analysis, haze reaches 10.1%, obtains Transparent bottle made of polypropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com