Garment steamer

A garment steamer and host technology, applied in the field of garment steamers, can solve problems such as single ironing posture, inconvenient storage, installation and transportation, and cumbersome operation, and achieve the advantages of small overall space occupation, convenient packaging and transportation, and improved comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

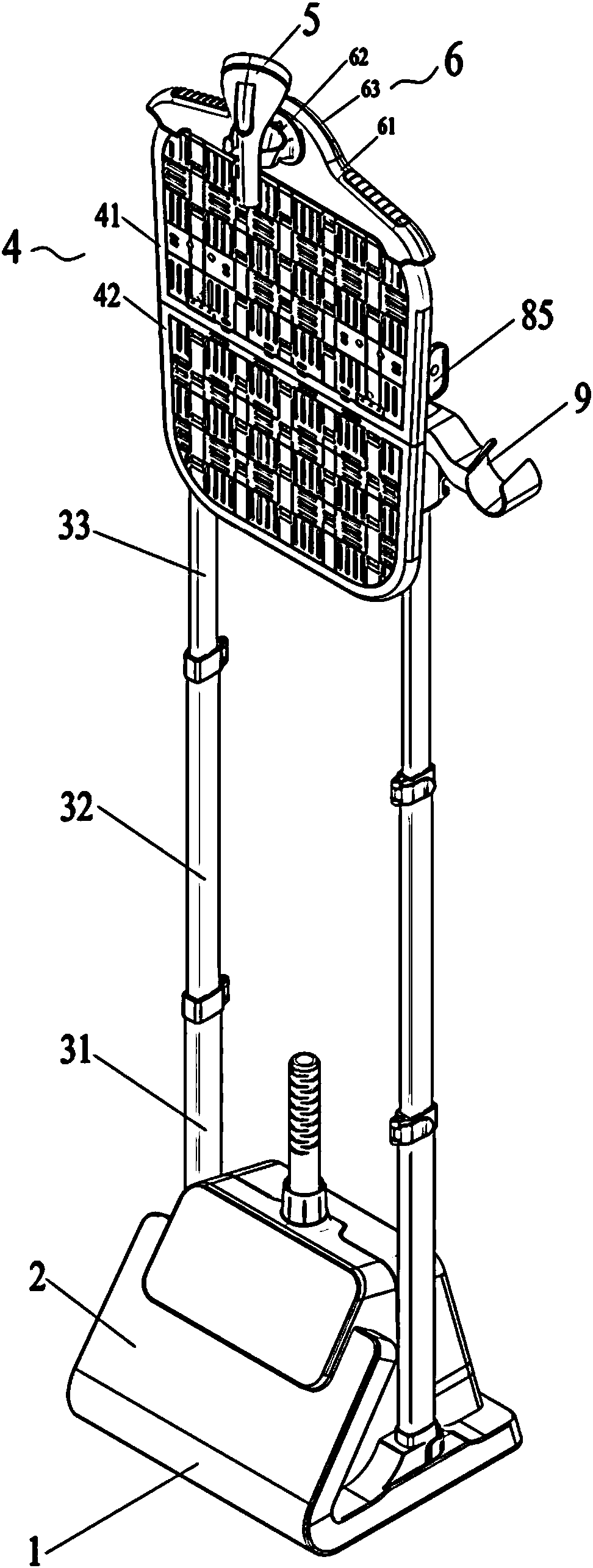

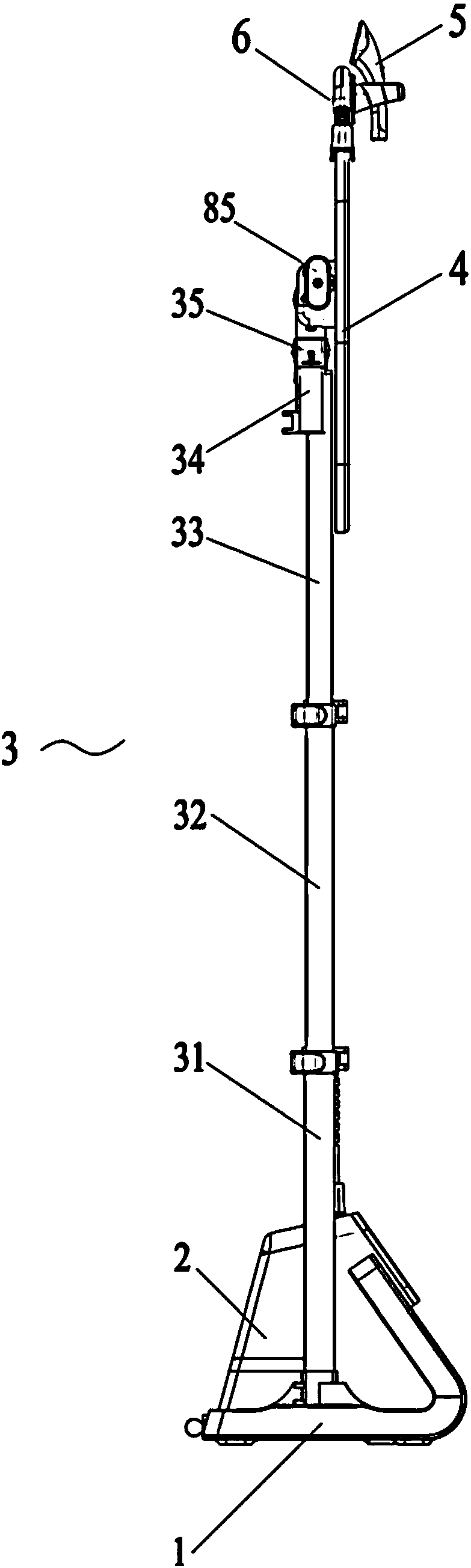

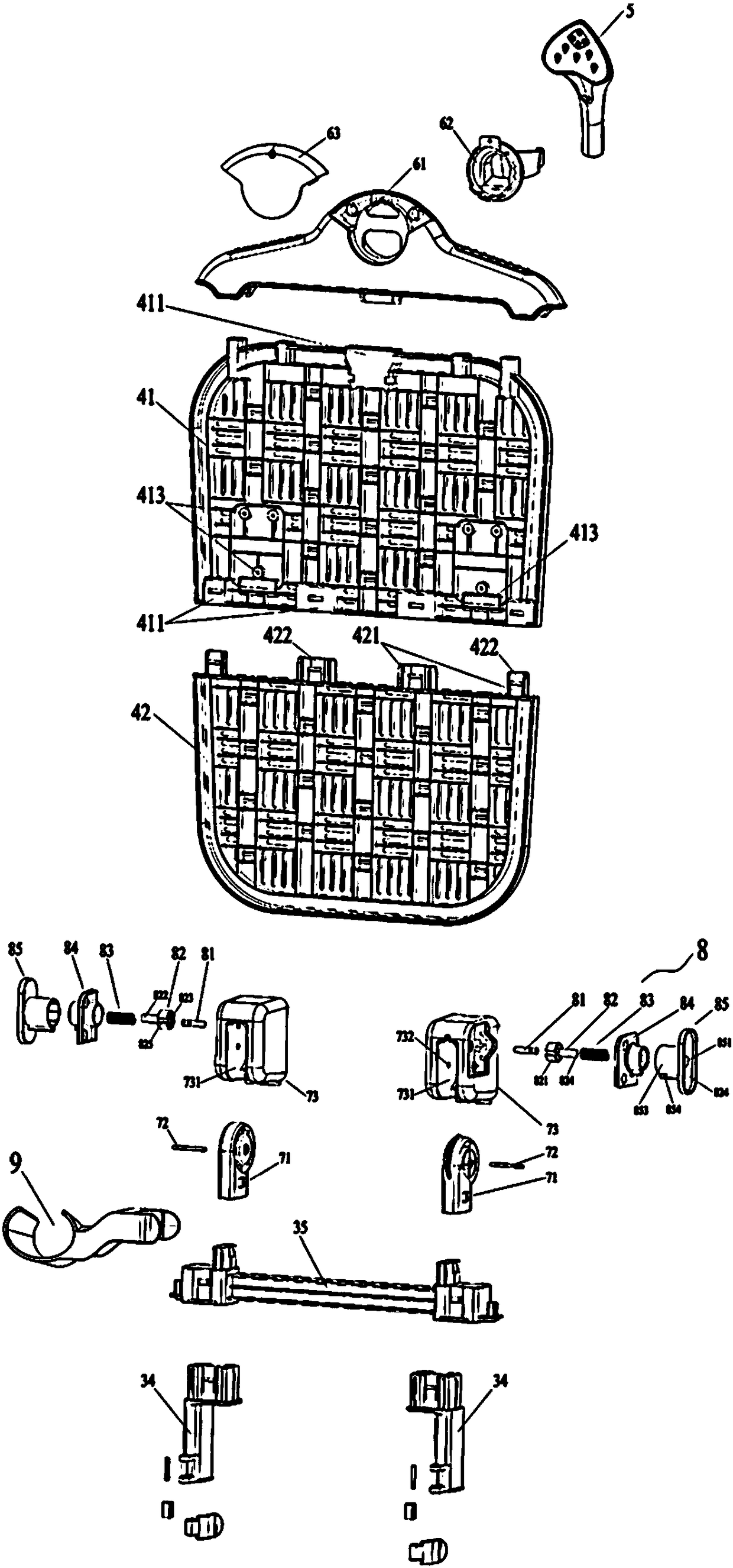

[0050] combine Figure 1 to Figure 3 As shown, a garment steamer includes a base 1, a host 2, a support rod assembly 3, an ironing board 4, a nozzle 5 and a hanger assembly 6,

[0051] The host 2 is fixedly installed on the base 1, and the host 2 is provided with a water tank, a steam generator and a control circuit board;

[0052] The bottom end of the support rod assembly 3 is fixedly connected to the base 1, and the top end of the support rod assembly 3 is connected to the ironing board 4 through a rotating mechanism 7;

[0053] The ironing board 4 can rotate relative to the support rod assembly 3 from a vertical state to a horizontal state, and can be fixed by a limit mechanism 8 at multiple rotation angles;

[0054] The clothes hanger assembly 6 is installed on one side of the ironing board 4, the spray head 5 is detachably installed on the clothes hanger assembly 6, and communicates with the steam generator through a steam guide tube for Iron with jet of steam.

[005...

Embodiment 2

[0096] Such as Figure 9 and Figure 10 As shown, a garment steamer includes a base 1, a host 2, a support rod assembly 3, an ironing board 4, a nozzle 5 and a hanger assembly 6,

[0097] The host 2 is fixedly installed on the base 1, and the host 2 is provided with a water tank, a steam generator and a control circuit board;

[0098] The bottom end of the support rod assembly 3 is fixedly connected to the base 1, and the top end of the support rod assembly 3 is connected to the ironing board 4 through a rotating mechanism 7;

[0099] The ironing board 4 can rotate relative to the support rod assembly 3 from a vertical state to a horizontal state, and can be fixed at multiple rotation angles by a limiting mechanism;

[0100] The clothes hanger assembly 6 is installed on one side of the ironing board 4, the spray head 5 is detachably installed on the clothes hanger assembly 6, and communicates with the steam generator through a steam guide tube for Iron with jet of steam.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com