A construction method and structure for frost heave prevention of excavated channels in alpine regions

A construction method and anti-frost heave technology, which is applied in artificial waterways, water conservancy projects, buildings, etc., can solve the problems of concrete frost heave damage, poor anti-frost heave effect, anti-frost heave structure damage, etc. Good swelling effect and strong anti-ice pushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below through specific examples.

[0032] A method for preventing frost heave in deep excavation channels in alpine regions, the method steps are as follows:

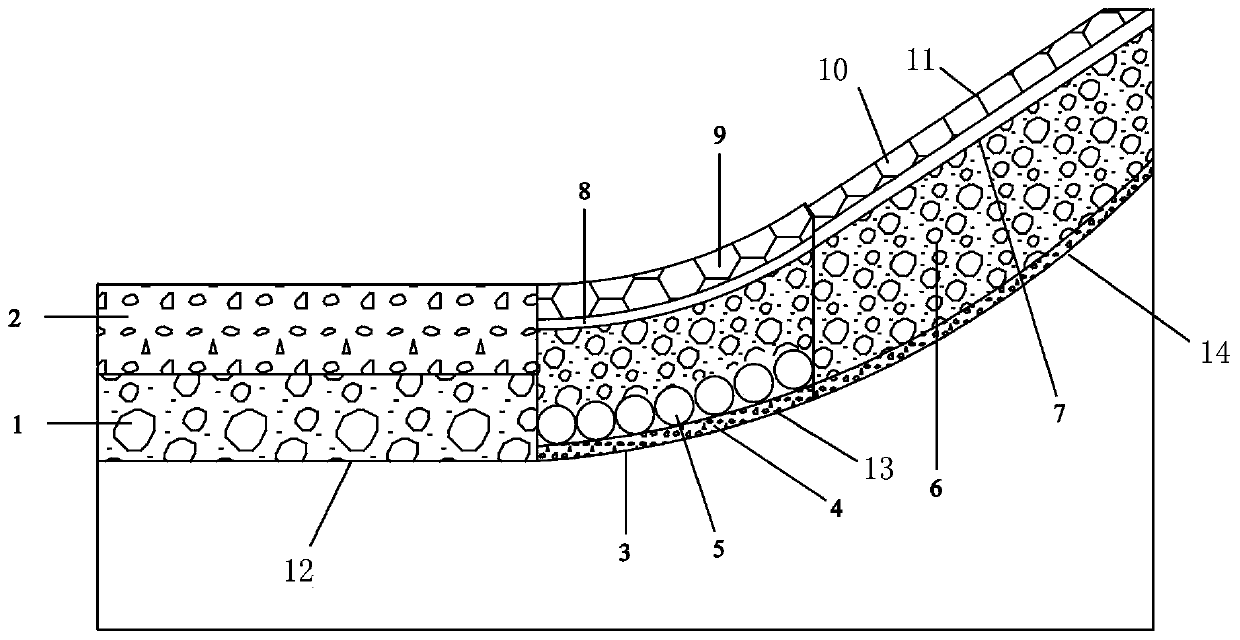

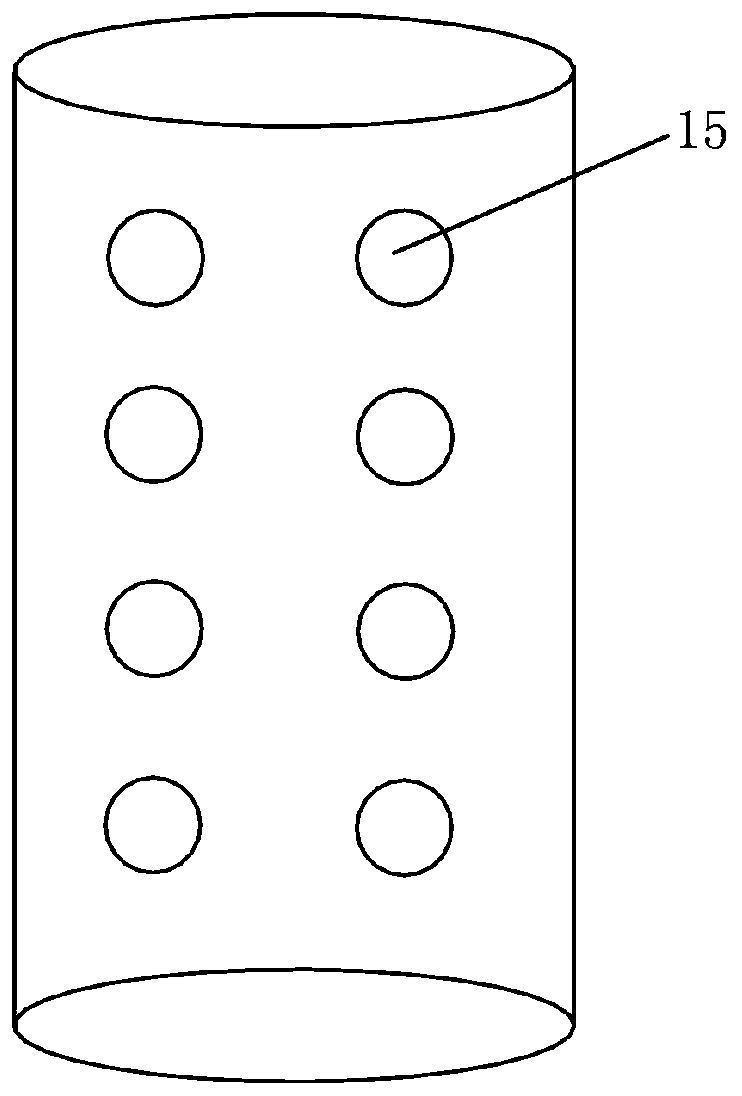

[0033] 1) The bottom of the canal slope is an arc-shaped section with an arc length of 6.0m, a canal inclination angle of 50°, and a canal bottom width of 10m. The soil is rolled and then leveled. After rolling, the compaction degree of the channel foundation soil is 1.65g / cm 3 Above, make the channel bottom 12 foundations after leveling, the arc connection section 13 and the channel slope 14 on a horizontal plane in the direction of the water flow, the arc connection section 13 and the channel slope 14 are connected smoothly, and lay on the channel bottom 12 foundation soil Large coarse aggregate 1, the large coarse aggregate 1 is laid along the water flow direction, the thickness of the large coarse aggregate 1 is 40-60cm, preferably 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com