Overwintering protection coiled material for seasonal frozen soil engineering and construction method

A construction method and seasonal technology, which is applied in winter protection coils and construction fields of seasonal frozen soil engineering, can solve the problems of inability to guarantee the integrity of the heat preservation area, difficult to handle, and low efficiency of winter heat preservation, so as to avoid the formation of frozen soil And development, prevention of seasonal frozen soil, good heat preservation and antifreeze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

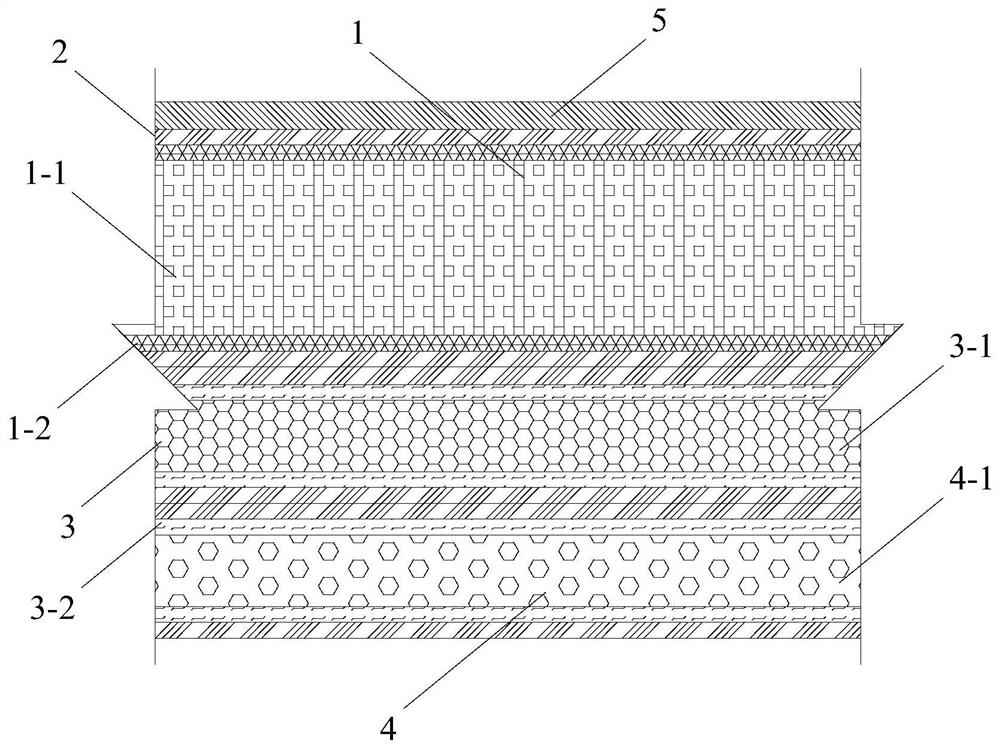

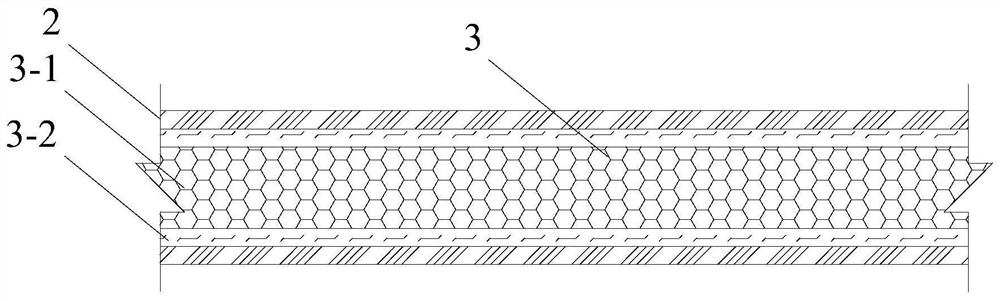

[0050] Such as figure 1 As shown, a winter protection coil for seasonal frozen soil engineering provided by the embodiment of the present invention, from top to bottom is a fireproof and waterproof coil 5, a thermal insulation coil 1 and a moisture-absorbing coil;

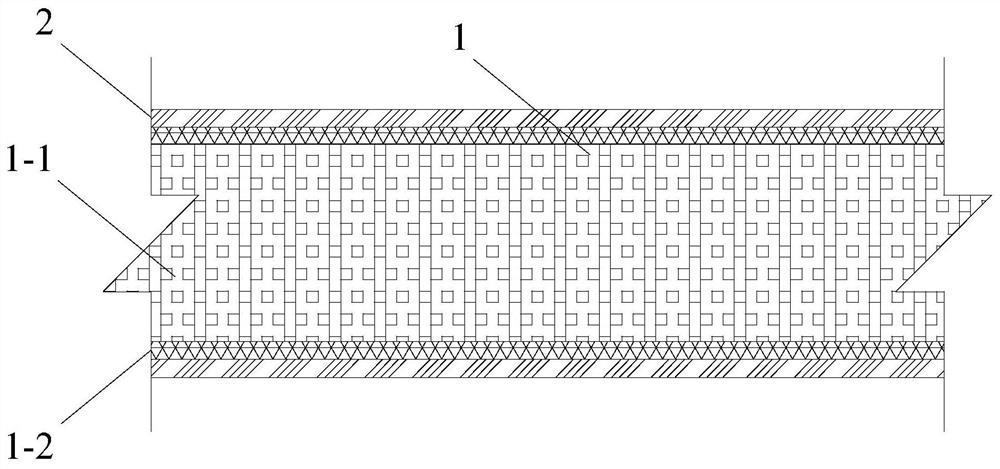

[0051] The thermal insulation coiled material 1 includes thermal insulation material 1-1; the outer side of the thermal insulation material 1-1 wraps the first protective layer 1-2 and the bonding protective layer 2 in turn; the first protective layer 1-2 is a watertight seal The material is provided with a one-way ventilation valve; the thermal insulation material 1-1 is composed of perlite, high-strength fiber and nano-silica aerosol; the perlite is granular, and as the matrix of the thermal insulation material 1-1, it is composed of a Wrapped with a layer of high-strength fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com