Steel rail current drainage net transition resistance monitoring system and control method thereof

A transition resistance and monitoring system technology, applied in the field of rail transit, can solve the problems of manual wiring and reading errors, large labor consumption, random sampling, etc., and achieve the effects of ensuring reliability, saving space and cost, and reducing wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

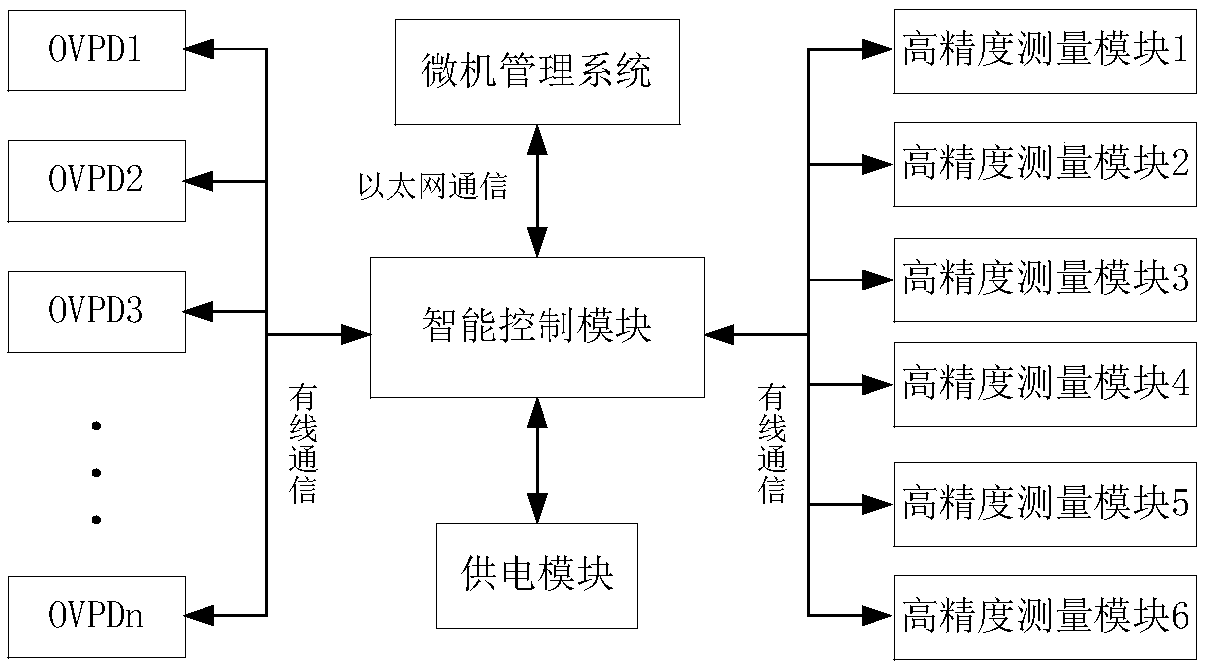

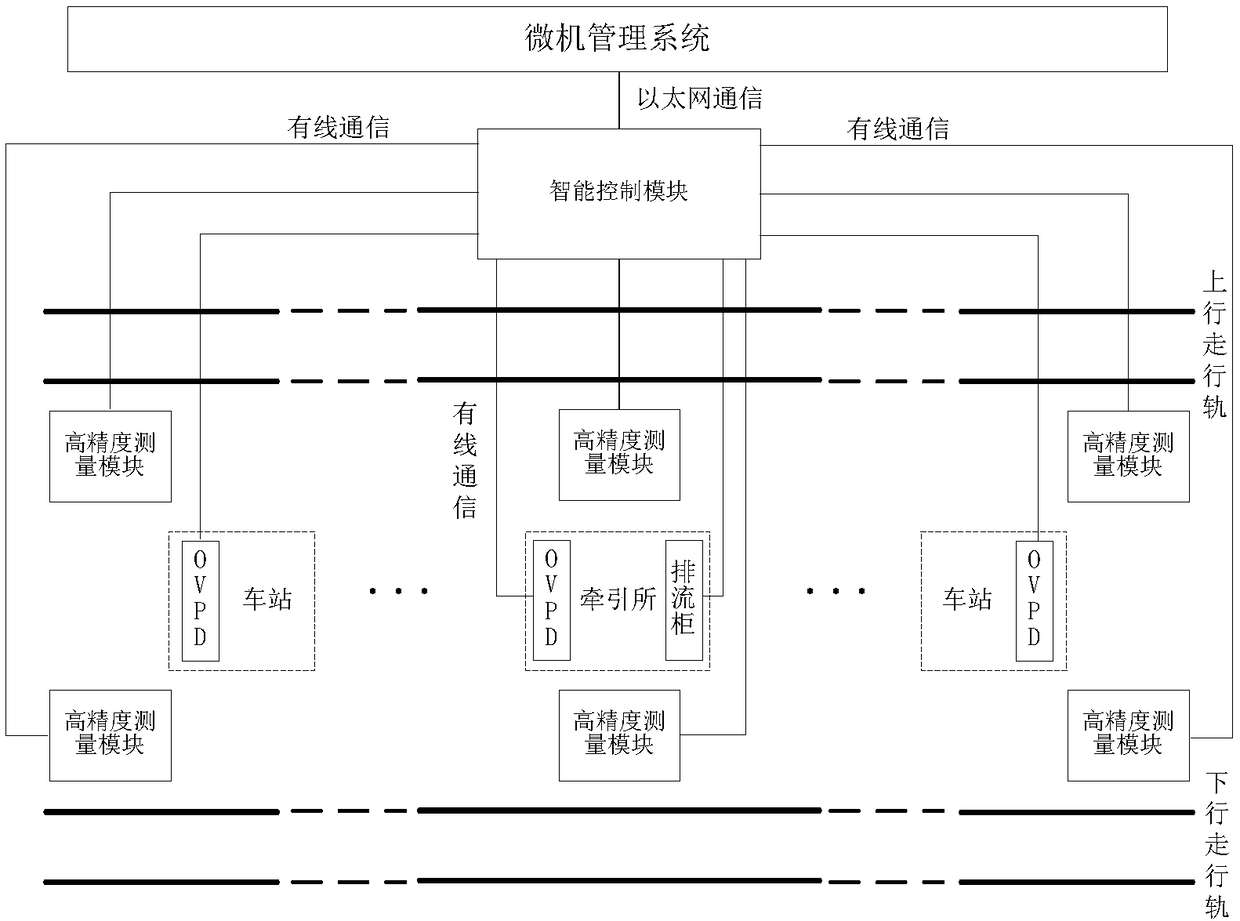

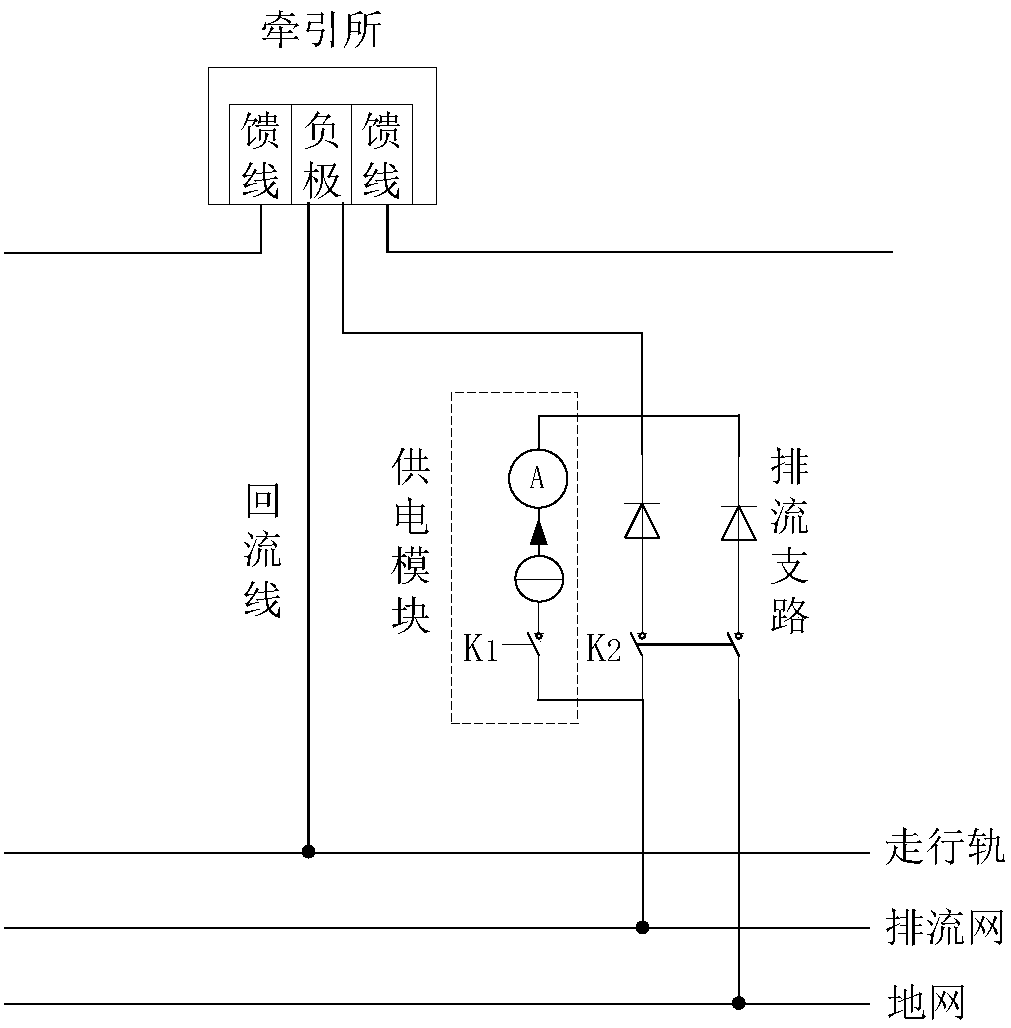

[0034] like figure 1 As shown, a rail-to-drain network transition resistance monitoring system includes an intelligent control module, a high-precision measurement module and a power supply module; the intelligent control module and the microcomputer management system are connected through an Ethernet interface; The drainage branch of the cabinet is connected through a communication cable to control the on-off of the power supply module and the drainage branch; the intelligent control module is connected to the high-precision measurement module and OVPD through a communication cable; OVPD has encoded the address, recorded the installation location, the length of the monitoring section, recorded the length of the monitoring section, and established a database to store and manage various information and monitoring data.

[0035] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com