A Fault Mode and Effect Analysis Method Based on Accident Dynamic Deduction Simulation

A technology of failure mode and impact analysis, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as inability to perform temporal logic, failure, analysis and combination functions, so as to facilitate the discovery and troubleshooting of system failures and reduce usage. Threshold, analysis results are true and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

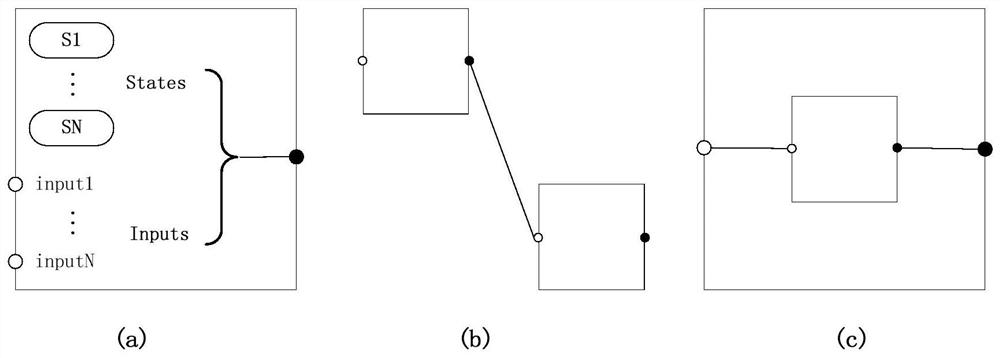

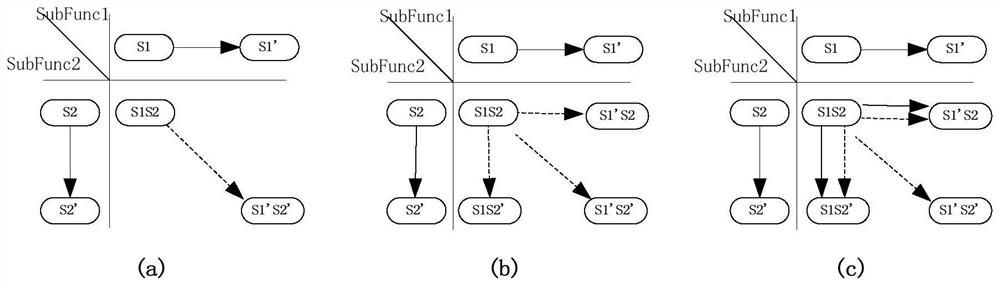

Method used

Image

Examples

Embodiment Construction

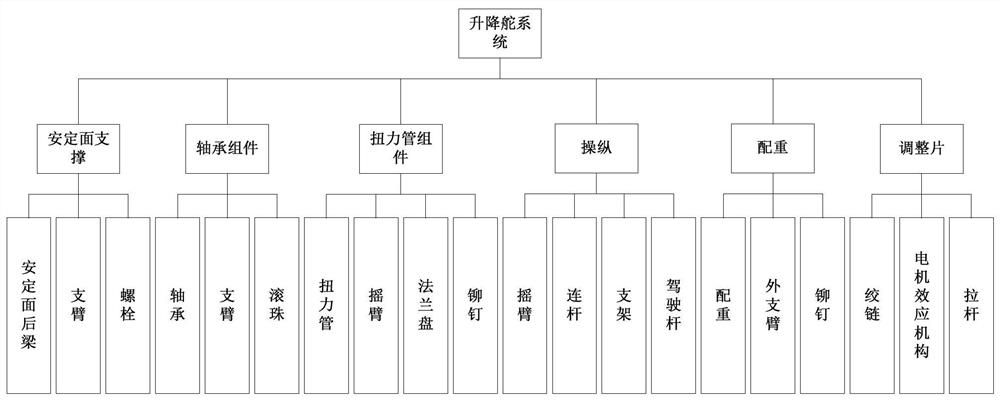

[0080] The technical solution of the present invention will be further described in detail and in-depth with reference to the drawings and embodiments below. Taking the aircraft elevator system as an example, the failure mode and impact analysis based on accident dynamic deduction simulation is carried out. The steps are as follows:

[0081] Step 1. According to the product agreement, product requirements and design documents of the analyzed object, describe the composition and function of the analyzed object. The analysis object is decomposed layer by layer, and decomposed to the lowest agreed level according to the needs of failure mode and effect analysis;

[0082] The composition and function of the system are described as follows: the elevator system is a single-beam box-type thin-walled structure, and a double-closed chamber section structure composed of beams, small beams, ribs, and skins. In order to ensure that the operation of the elevator system is required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com