Chip thinning-based cleaning method

A chip and LED chip technology, applied in the field of cleaning, can solve the problem of unclean silicon substrate cleaning, and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The essence of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the content of the present invention is not limited thereto.

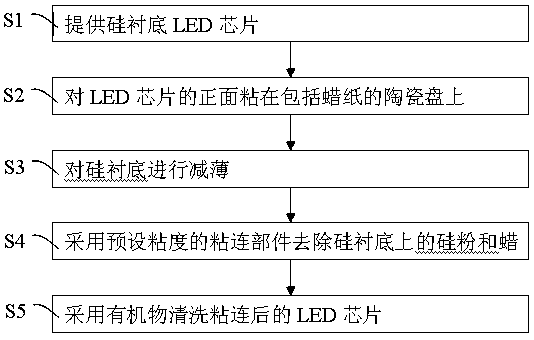

[0023] like figure 1 Shown is a schematic flow chart of the cleaning method based on chip thinning provided by the present invention. It can be seen from the figure that the cleaning method includes:

[0024] S1 provides silicon substrate LED chips;

[0025] S2 The front side of the LED chip is glued to the ceramic plate including the wax paper;

[0026] S3 Thinning the silicon substrate;

[0027] S4 removes the silicon powder and wax on the silicon substrate by using an adhesive part with a preset viscosity;

[0028] S5 Use organic matter to clean the bonded LED chips.

[0029] In this cleaning method, the adhesive part selected is preferably an adhesive film, such as the blue film widely used in laboratories at present, and the viscosity range is selected between 0.5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com