Chinese herbal medicine grinding equipment

A technology of Chinese herbal medicine and equipment, applied in the field of Chinese herbal medicine grinding equipment, can solve the problems of low efficiency, inconvenient use, insufficient grinding and pulverizing, and achieve the effects of sufficient grinding, improving efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

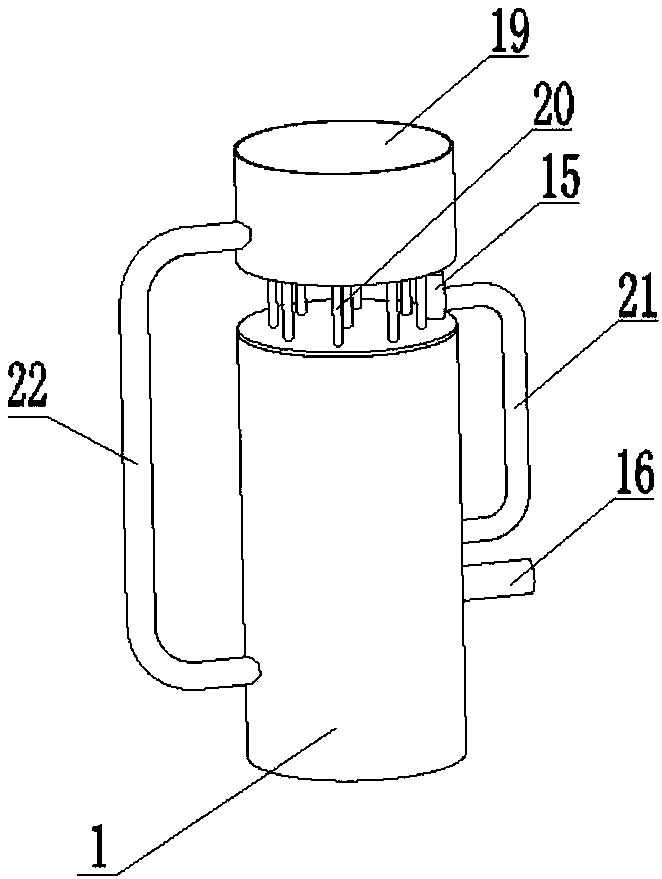

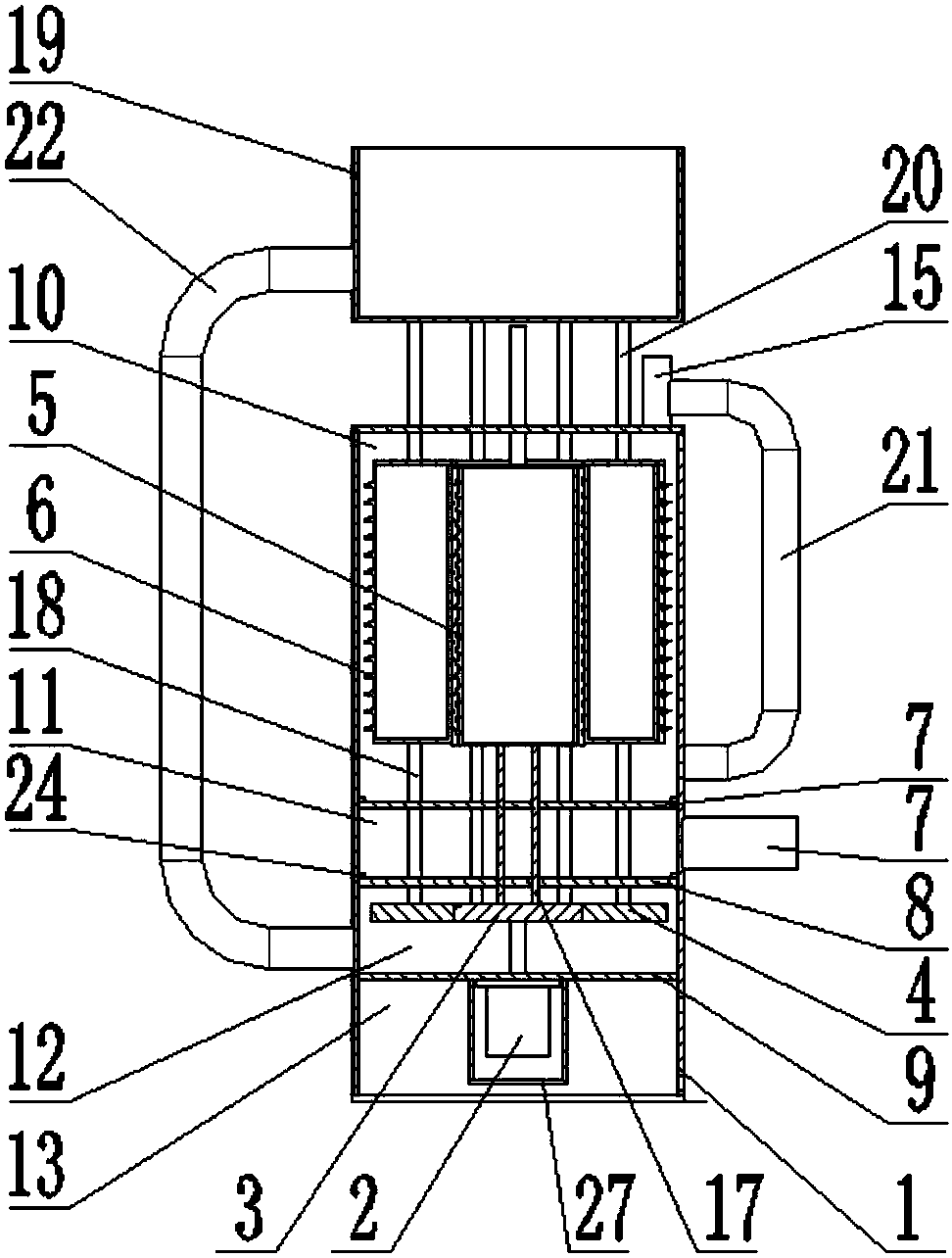

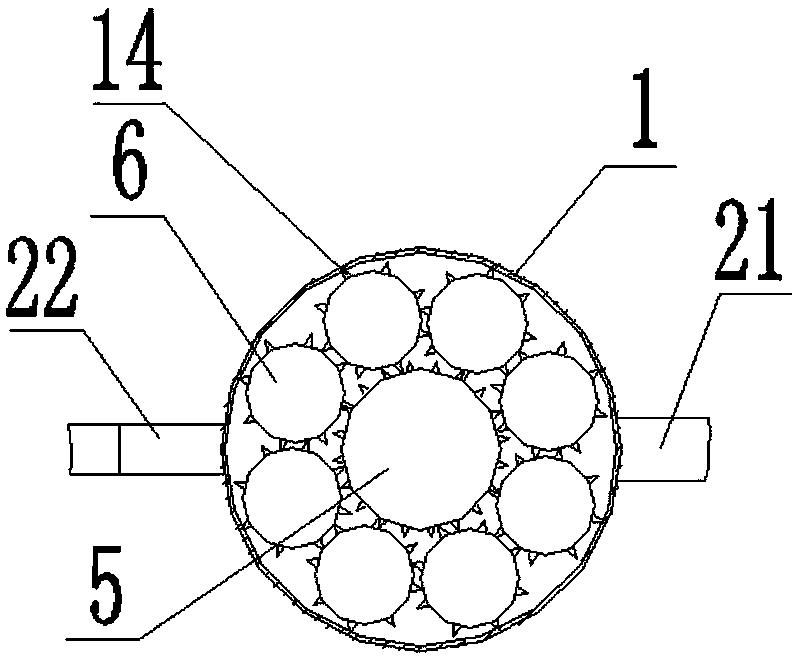

[0026] Such as Figure 1 to Figure 8 As shown, the present invention provides a kind of Chinese herbal medicine grinding equipment, which includes a body 1, a motor 2, a driving gear 3, a driven gear 4, a grinding cylinder A5 and a plurality of grinding cylinders B6, and the body 1 is sequentially provided with screening equipment from top to bottom. The plate 7, the runner plate 8 and the partition plate 9 divide the body 1 from top to bottom into a grinding chamber 10, a collection chamber 11, a liquid collection chamber 12 and a transmission chamber 13, and the outer walls of the grinding cylinder A5 and grinding cylinder B6 There are a plurality of grinding bodies 14 on each of them, a feed pipe 15 is provided above the grinding chamber 10, a discharge pipe 16 is provided on the outer wall of the collection chamber 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com