Automatic cutoff device for heat shrinkage sleeve

An automatic cutting and heat-shrinkable sleeve technology, which is applied in metal processing and other directions, can solve the problems of increasing manpower and labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

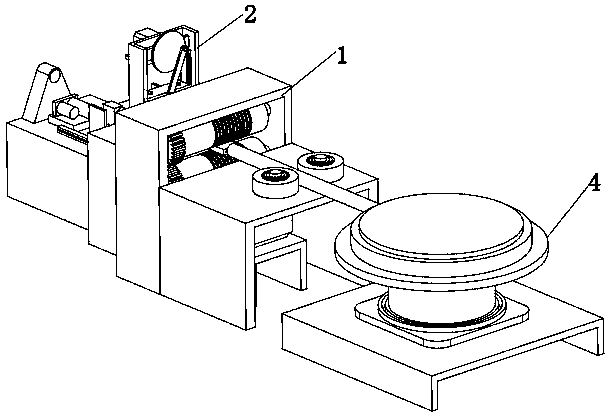

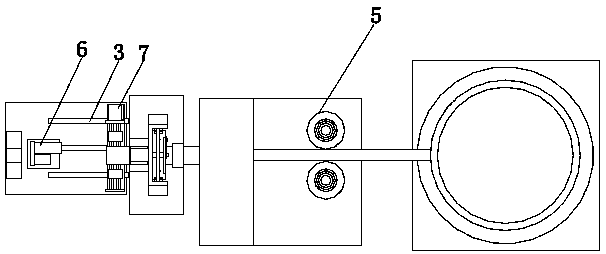

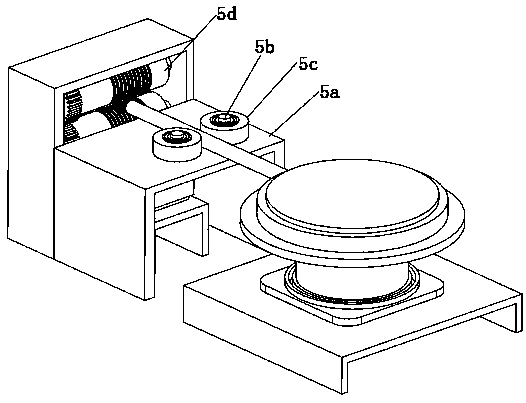

[0027] refer to Figure 1 to Figure 9 A heat-shrinkable sleeve automatic cutting device shown includes a feeding mechanism 1, a material cutting mechanism 2 and a pipe threading mechanism 3, and the material cutting mechanism 2 is located between the feeding mechanism 1 and the pipe threading mechanism 3, so The feeding mechanism 1 includes a stocking assembly 4 and a feeding assembly 5, the feeding assembly 5 is located between the stocking assembly 4 and the cutting mechanism 2, and the cutting mechanism 2 includes a support frame 2a, a cutting knife 2b and a driving assembly 8 for driving the cutting knife 2b to cut the workpiece, the driving assembly 8 is located on the top of the support bracket 2a, the cutting knife 2b is located directly above the support bracket 2a, and the cutting mechanism 2 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com