Winding mechanism for sunscreen

A technology of winding mechanism and sunshade screen, which is applied in the direction of vehicle subunit functions, windows, windshields, etc., and can solve the problems of the sunshade screen being rolled onto the winding tube due to the deployment force of the sunshade screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

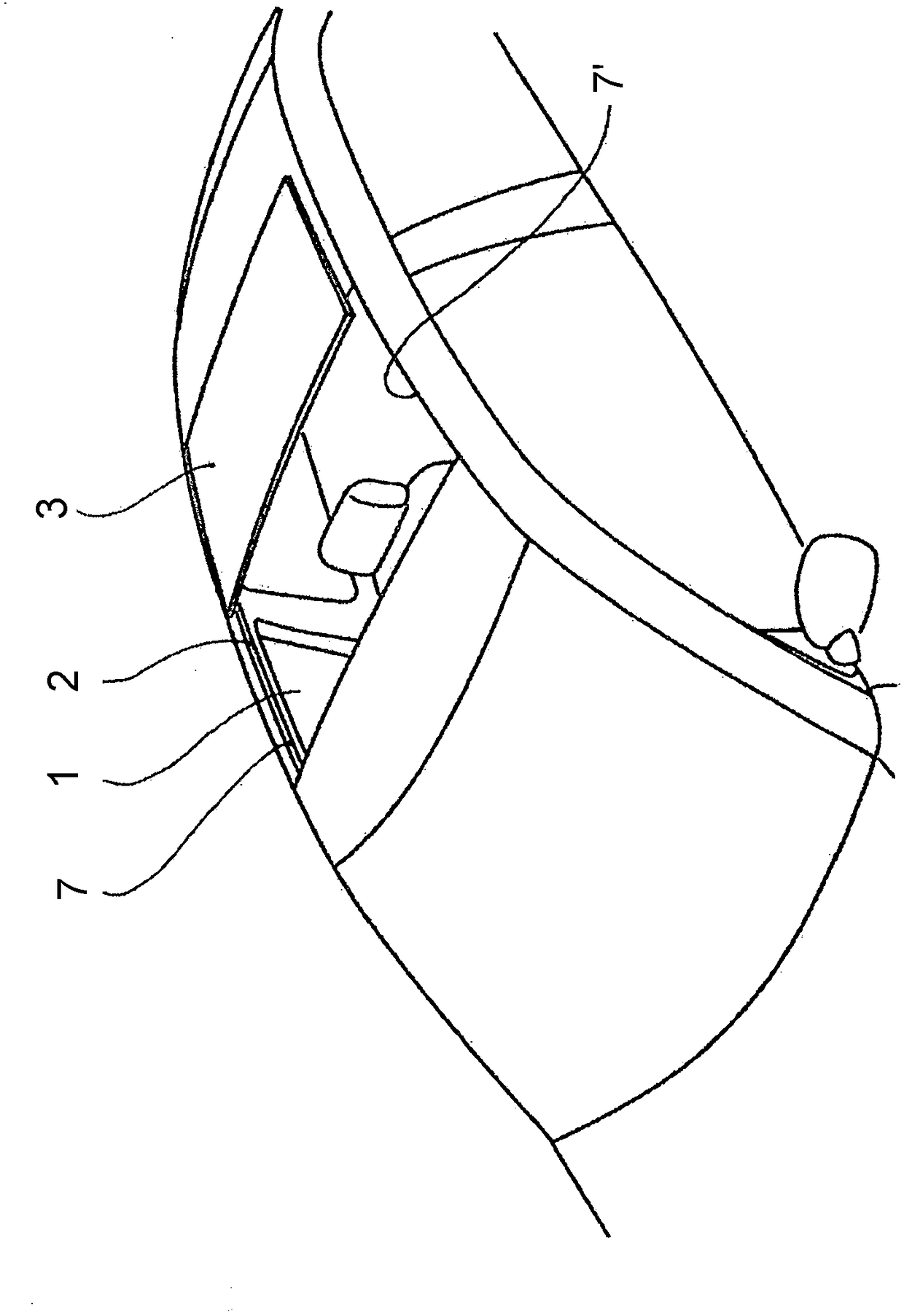

[0041] refer to figure 1 , showing a part of a vehicle with a fixed roof provided with an open roof construction. As shown, there is a roof opening 1 defined in the fixed part 2 of the open roof construction.

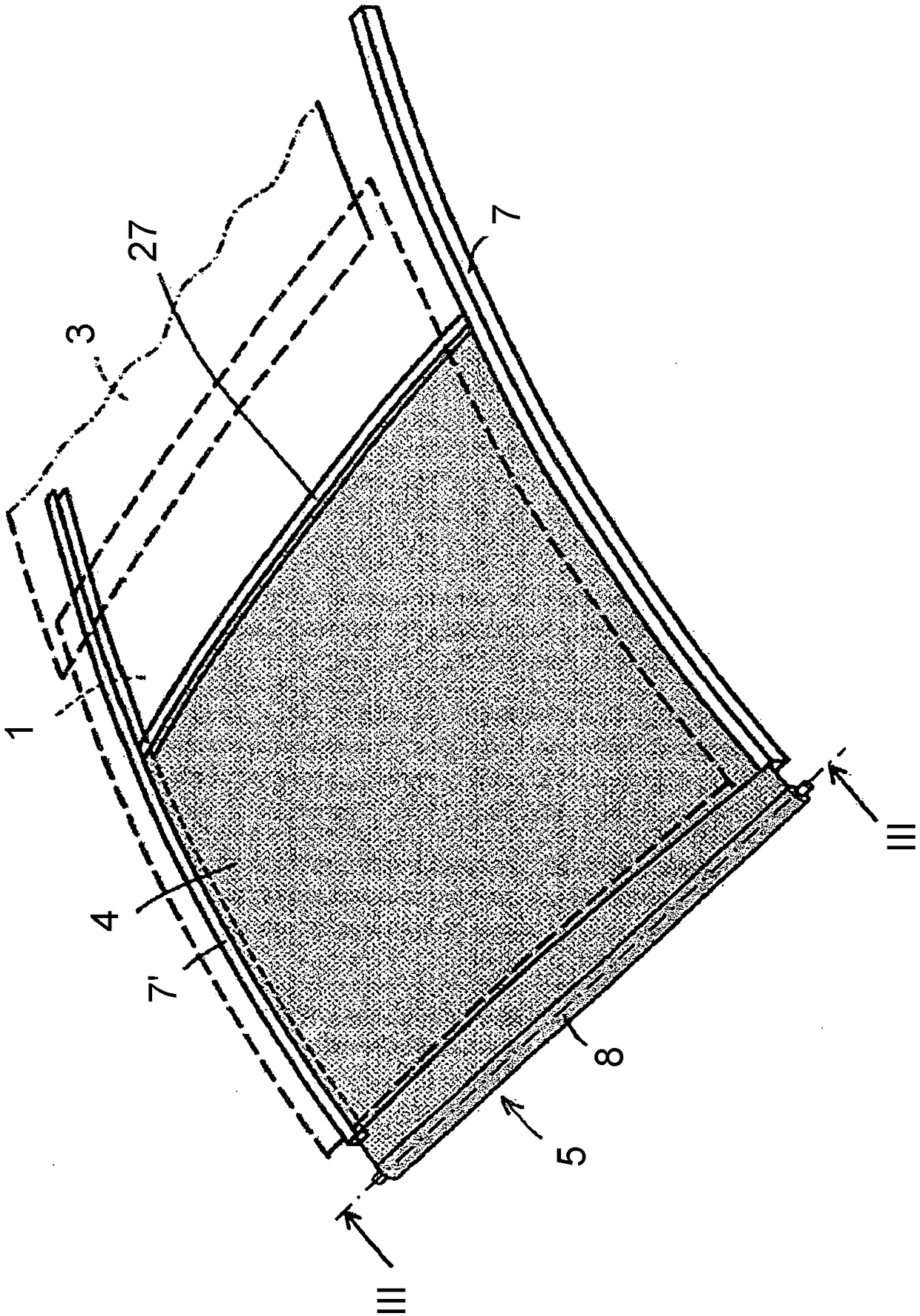

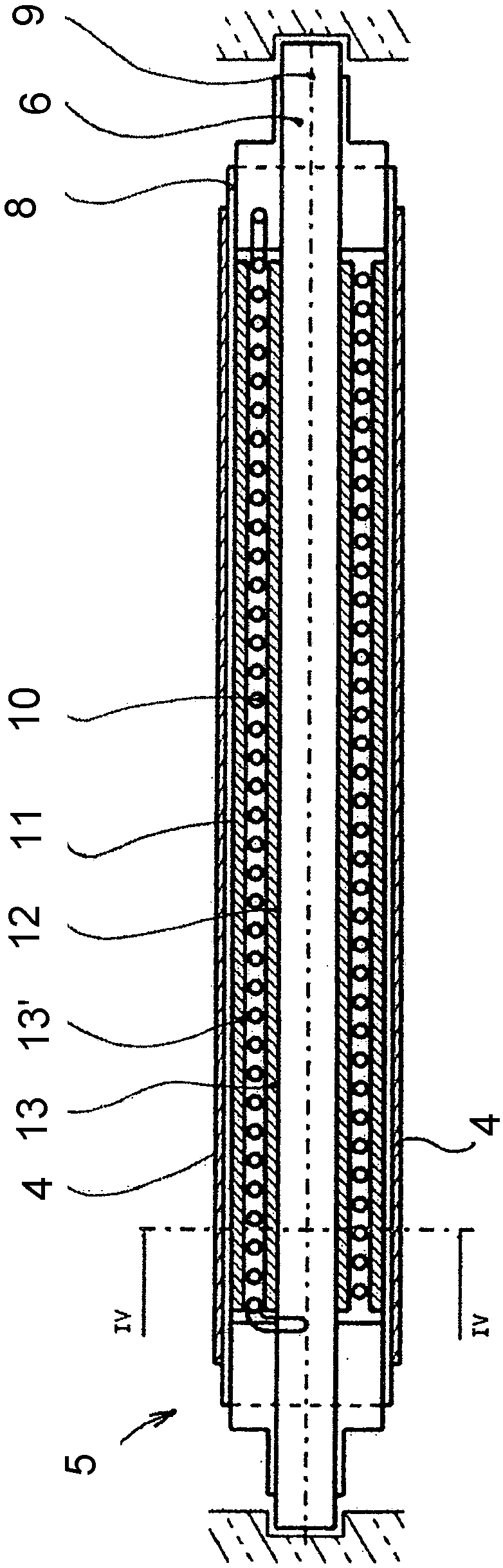

[0042] At least one movable closing member (here an at least partially transparent, rigid panel 3 ) for opening and closing said roof opening 1 is provided. figure 2 A sun visor assembly is shown, which cooperates with said roof opening 1 for covering the roof opening 1 from below in order to partially or completely prevent sunlight from entering the vehicle part. The sunshade assembly basically includes a flexible sunshade 4, a rotatable winding mechanism 5 for winding or unrolling the flexible sunshade 4, and two long shafts for cooperating with a corresponding one of the longitudinal sides of the sunshade 4. Strip-shaped guide members 7, 7'. The lateral edge of the sun visor 4 remote from the winding mechanism 5 is provided in a manner known per se with an operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com