Constant force device based on air spring and use method of constant force device

A technology of constant force device and air spring, which is applied in the field of constant force device, can solve the problems of low friction, low damping, low stiffness, etc., and achieve the effects of fast response, improved precision, and accurate pressure compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

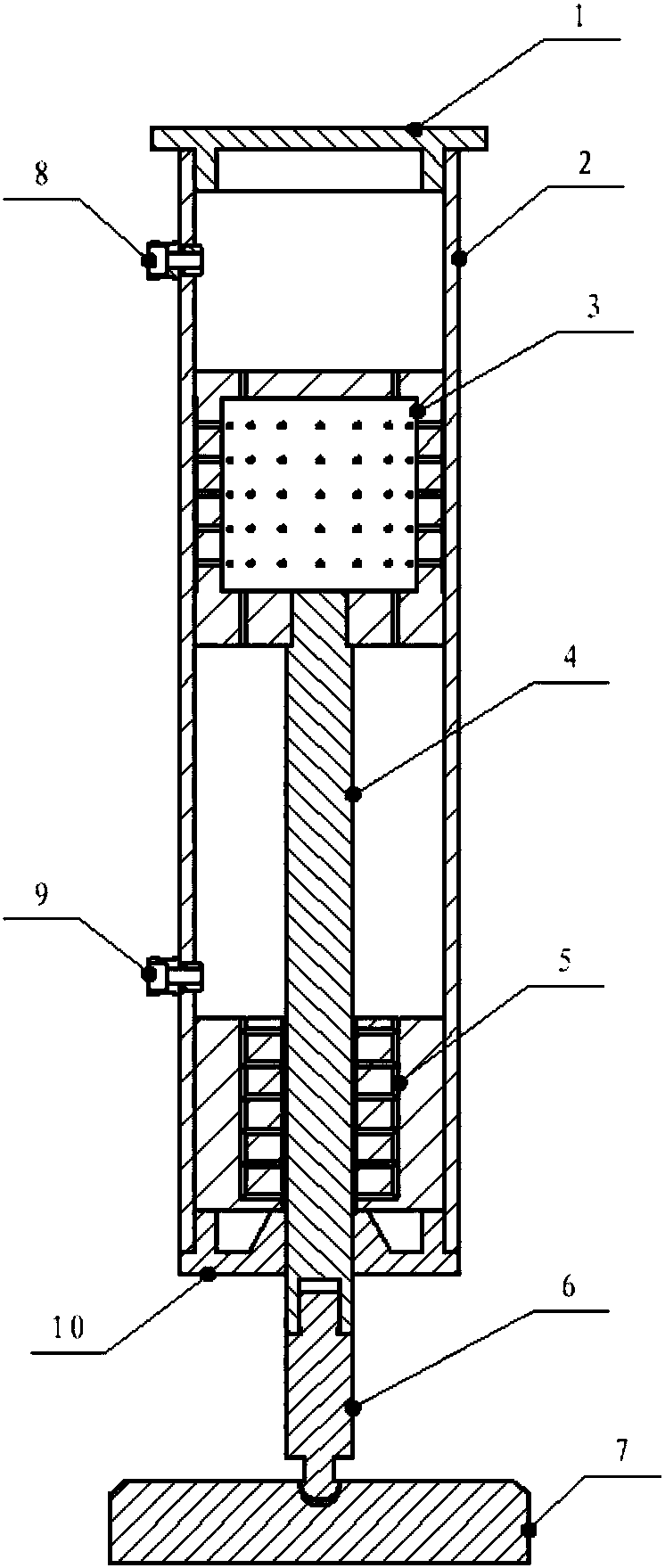

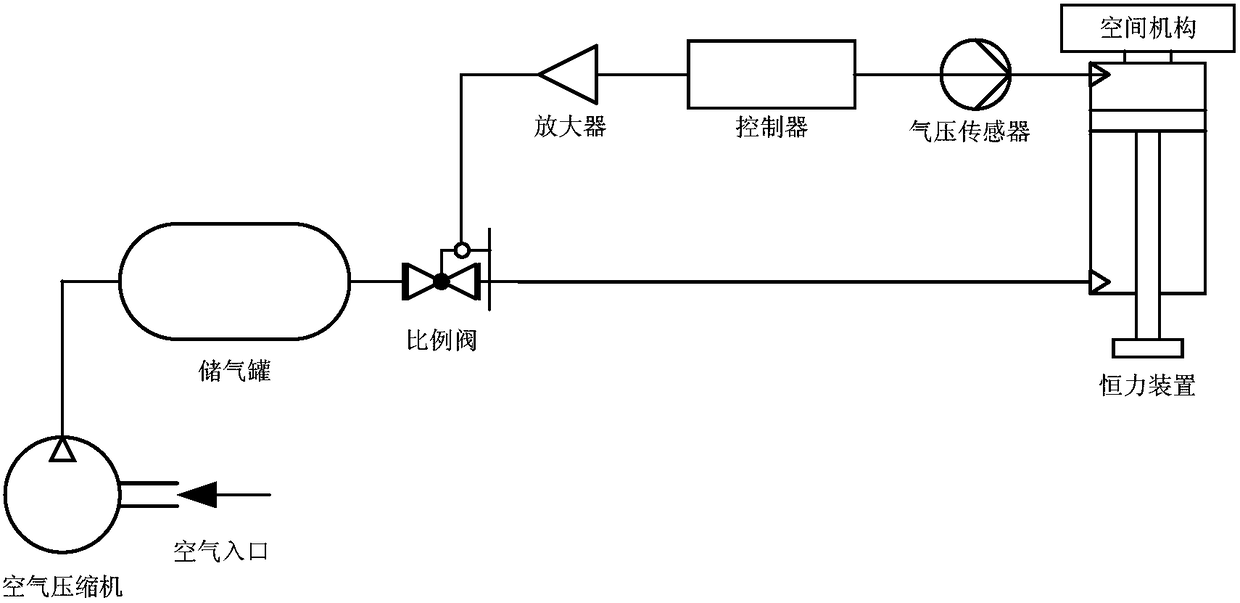

[0024] Such as figure 1 , figure 2 As shown, a constant force device based on an air spring includes a mechanism adapter 1, a cylinder body 2, an air suspension piston 3, a piston rod 4, an air bearing 5, a screw rod 6, and an air bearing 7. Air plugs 8, 9 and air bearing block 10.

[0025] The mechanism adapter 1 is the installation interface of the space mechanism, which is connected with the cylinder body 2 through threaded connection or adhesive connection, and at the same time ensures the airtightness of the connection; the air-suspended piston 3 is a hollow cavity structure, 2 Clearance fit is the moving part in the device. There are several throttle holes in the radial layout, and several throttle hole air supply channels in the axial layout. It is connected with the piston rod 4 through threads. The air suspension piston 3 radial The orifice connects the cavity in the air suspension piston 3 with the side wall, and the air supply passage of the throttle hole in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com