A transport box removable shock absorption assembly

A technology of transport boxes and components, applied in the direction of transport and packaging, containers and packaging to prevent mechanical damage, etc., can solve the problems of easy bumping of transport boxes, shortened shelf life, perishable fruits and vegetables, etc., to ensure safe transportation, easy replacement, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

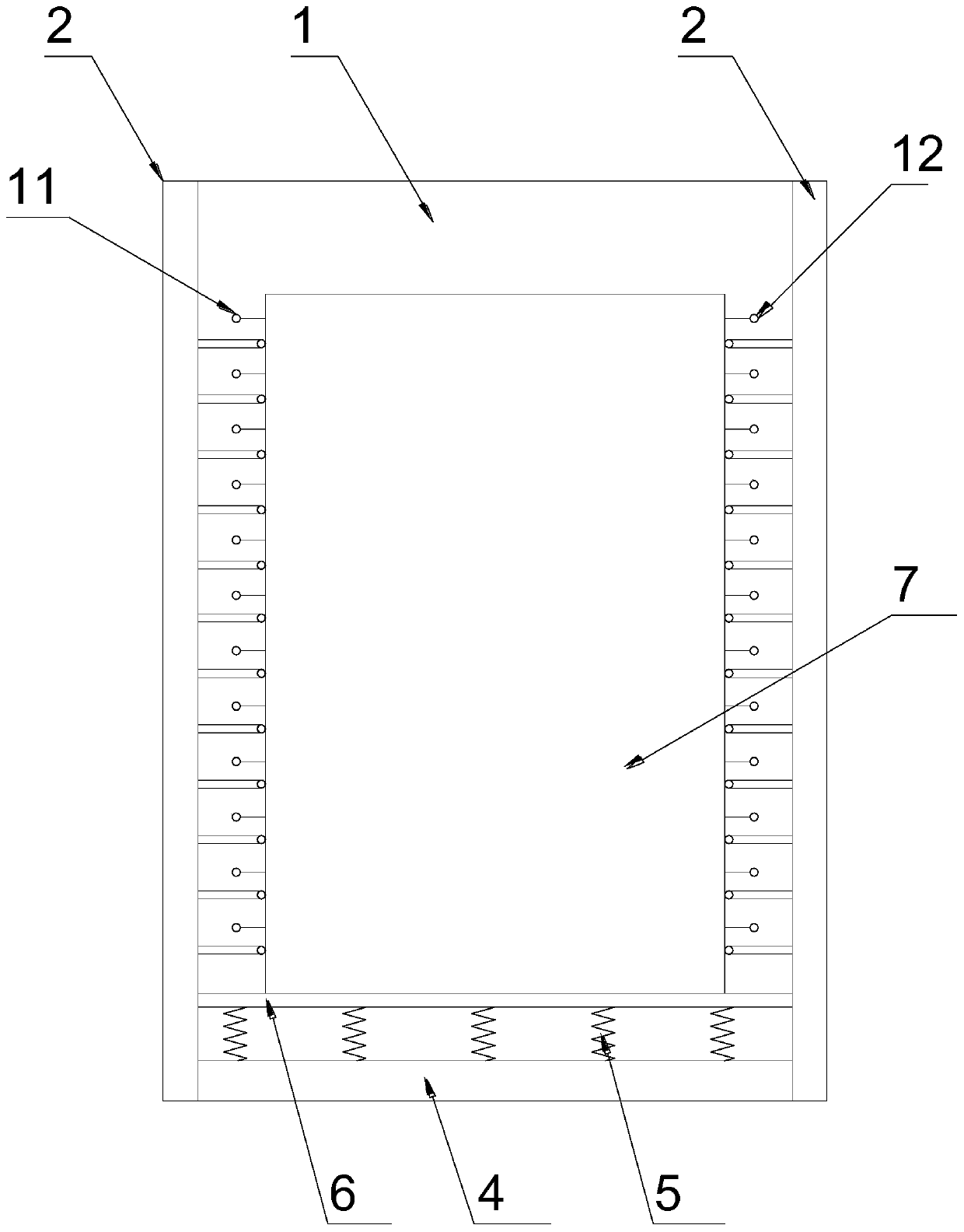

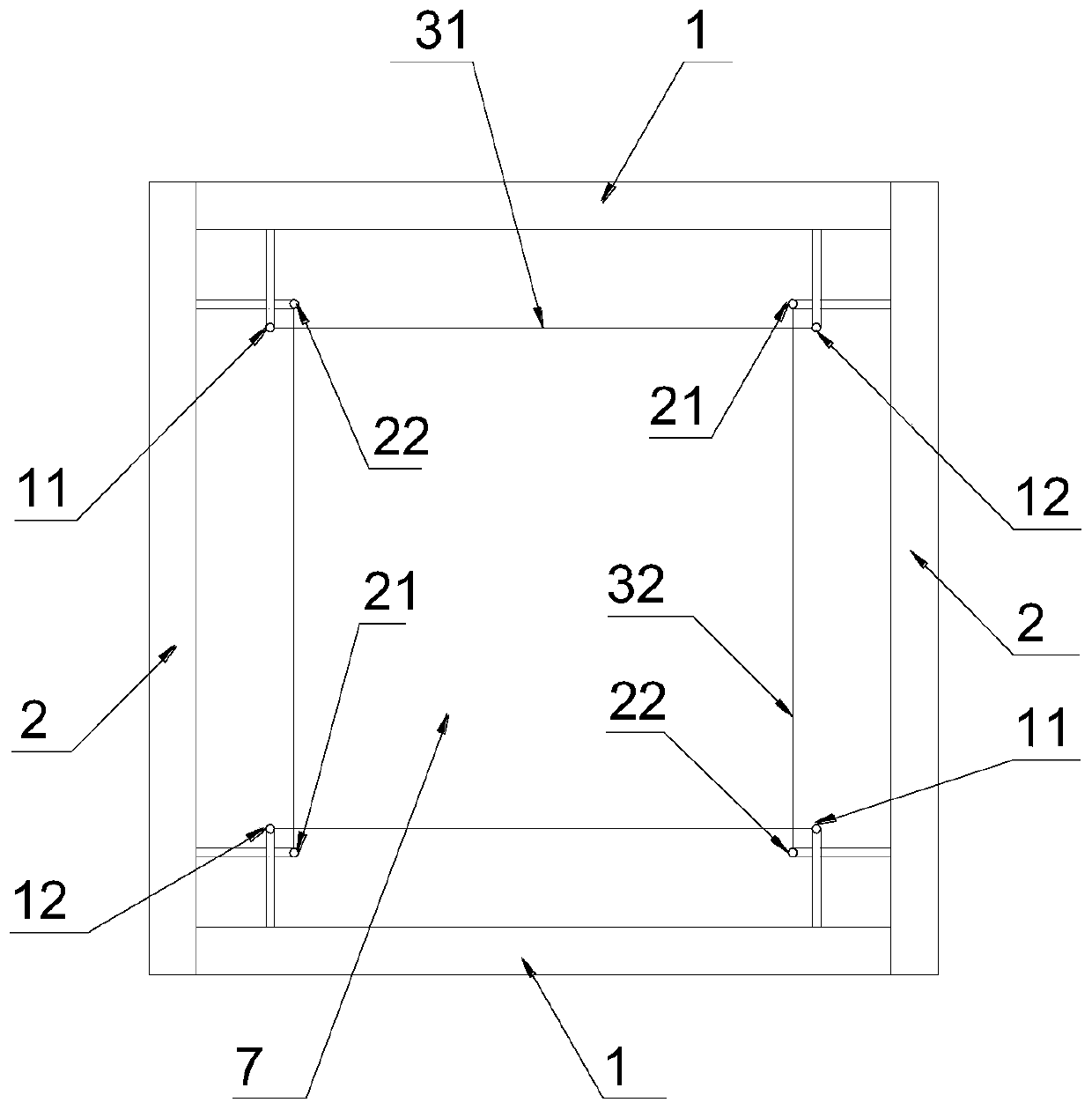

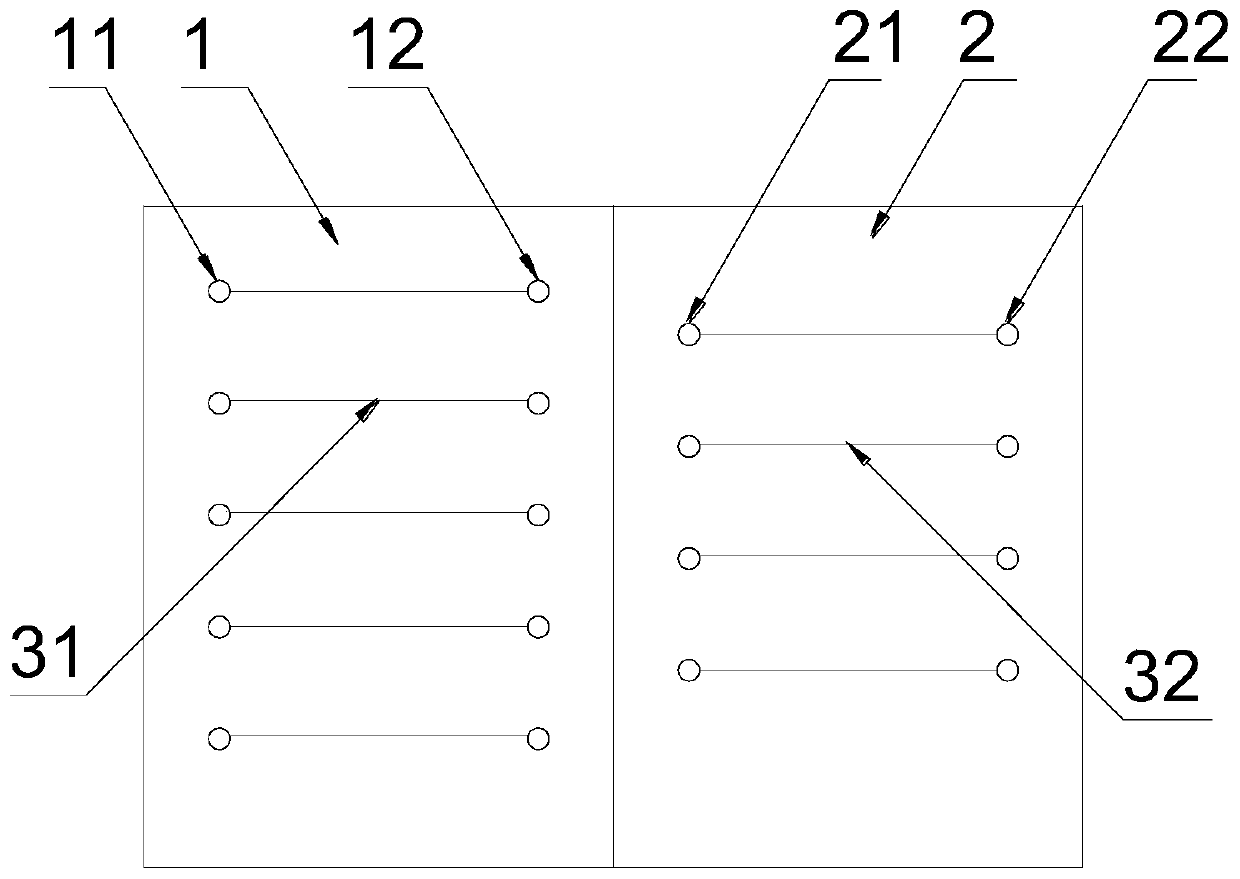

[0018] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a detachable shock-absorbing assembly of a transport box proposed by the present invention, figure 2 It is a schematic top view when the first baffle plate and the second baffle plate are connected to form a square shell in the detachable shock-absorbing assembly of the transport box proposed by the present invention, image 3 It is a schematic diagram of side-by-side placement of the first baffle and the second baffle in the detachable shock-absorbing assembly of the transport box proposed by the present invention.

[0019] refer to Figure 1-3 , a detachable damping assembly for a transport box proposed by the present invention, including a first baffle plate 1, a second baffle plate 2, a bottom plate 4, a pole and a support plate 6; wherein, two first baffle plates 1 and two The second baffle plate 2 is connected successively to form a square shell; the first baffle plate 1 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com