Ship shaft power wireless test and performance assessment device

A shaft power and performance technology, applied in the field of shaft power wireless detection and performance evaluation devices based on strain gauges, can solve the problems of not being suitable for dynamic evaluation of the shaft state, loss of wireless transmission signals, and poor versatility, etc., to achieve anti- Strong interference ability, small signal loss, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

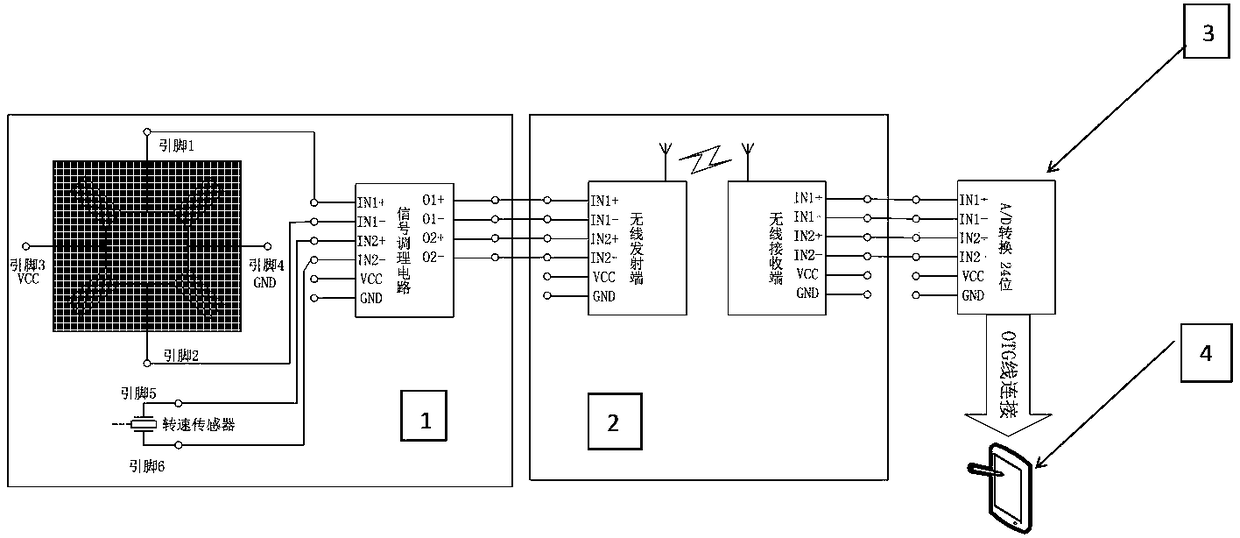

[0016] figure 1 The reference number 1 is the strain gauge axial power detection module including packaged strain gauges, rotational speed sensor, and signal conditioning module. Pin 3 of the strain gauge is the power inlet, pin 4 is grounded, pins 1 and 2 are connected to the IN1+ and IN1- input interfaces of the signal conditioning circuit, pins 5 and 6 of the speed sensor are connected to the IN2+ and IN2- input of the signal conditioning circuit The interface is connected. The output terminals O1+, O1-, O2+, O2- of the signal conditioning circuit are respectively connected to the input interfaces IN1+, IN1-, IN2+, IN2- of the wireless transmitting module.

[0017] figure 1 The point-to-point data transmission module described in No. 2 includes a signal transmitting and signal receiving module, two input and output. VCC is the power inlet, and GND is grounded. The I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com