Air conditioning unit joint debugging fixture system and control method thereof

An air-conditioning unit and joint debugging technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of poor stability and reliability, less lubricating oil in compressors, etc., and achieve shortening Effects of length, stable oil return, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

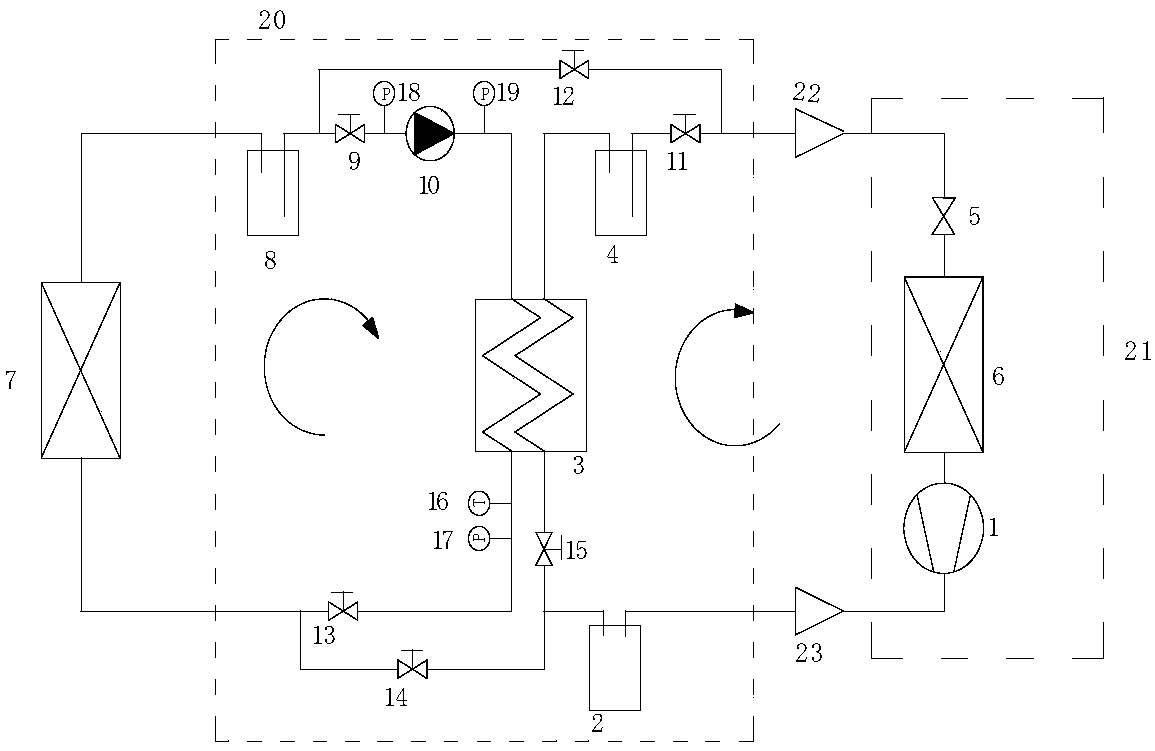

[0025] Such as figure 2 As shown, in the schematic block diagram of Embodiment 1 of an air conditioning unit joint adjustment tooling system of the present invention, it includes an indoor unit 21, an oil separator 2, a heat exchanger 3, a first liquid storage tank 4, a second liquid storage tank tank 8 , refrigerant pump 10 and condenser 7 , it can be understood that the indoor unit 21 includes a throttle valve 5 , an evaporator 6 and a compressor 1 .

[0026] It can be understood that the indoor unit 21, the oil separator 2, the heat exchanger 3, and the first liquid storage tank 4 are sequentially connected through pipelines to form an indoor circulation loop; the condenser 7, the second liquid storage tank 8, and the refrigerant pump 10 are connected through pipelines Connect in sequence to form an outdoor circulation loop. The indoor and outdoor circulation loops exchange heat through the heat exchanger 3, that is, the refrigerant pump 10 provides power for the outdoor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com