Rack forward driving type bowl seedling taking tail end executing mechanism

A drive-type, rack-and-rack technology, applied in the field of operating mechanisms, can solve the problems of reducing the quality and effect of pot seedling planting, damaging seedling leaves, and affecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

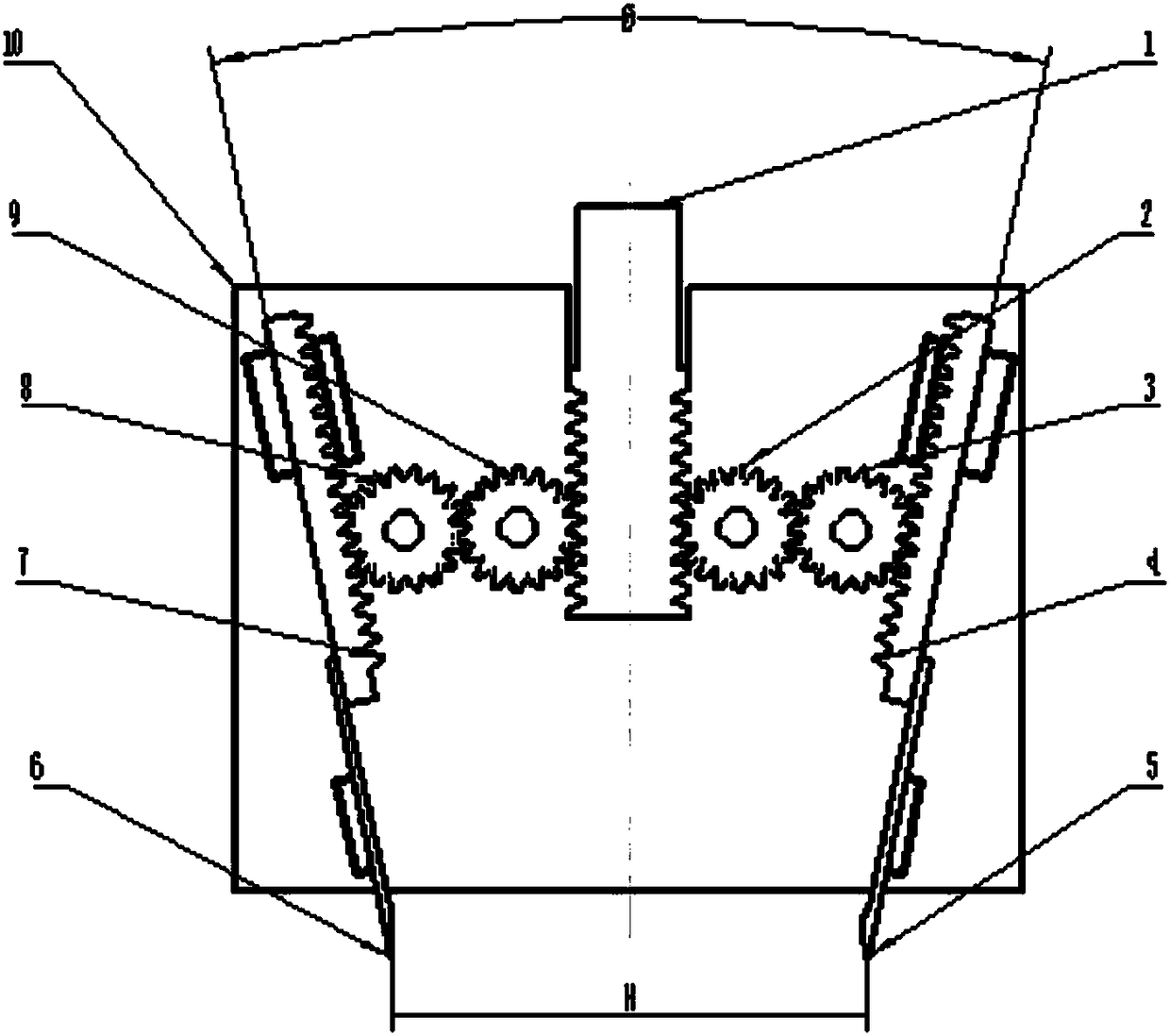

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rack forward-driven end actuator for pot seedling picking includes a pot seedling planting arm 10, on which a double-sided drive rack 1 is vertically movable up and down, and on the pot seedling planting arm 10 On the planting arm 10, a right drive gear 2 and a right reversing gear 3 are rotatably installed in turn at the right side of the double-sided drive rack 1, and the right drive gear 2 is connected to the double-sided drive rack 1 and the right reversing gear respectively. Mesh to the gear 3, on the pot seedling planting arm 10, the left drive gear 9 and the left reversing gear 8 are rotatably installed successively at the left side of the double-sided drive rack 1, and the left drive gear 9 is respectively Engage with the double-sided driving rack 1 and the left reversing gear 8, on the described bowl seedling planting arm 10, at the right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com