Novel automatic sock takeoff device

An automatic sock removal device and a new type of technology, applied in clothing, applications, hangers, etc., can solve the problems of difficulty in uniform customization, easy to be worn, and troublesome use of automatic socks removal shoes and their devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

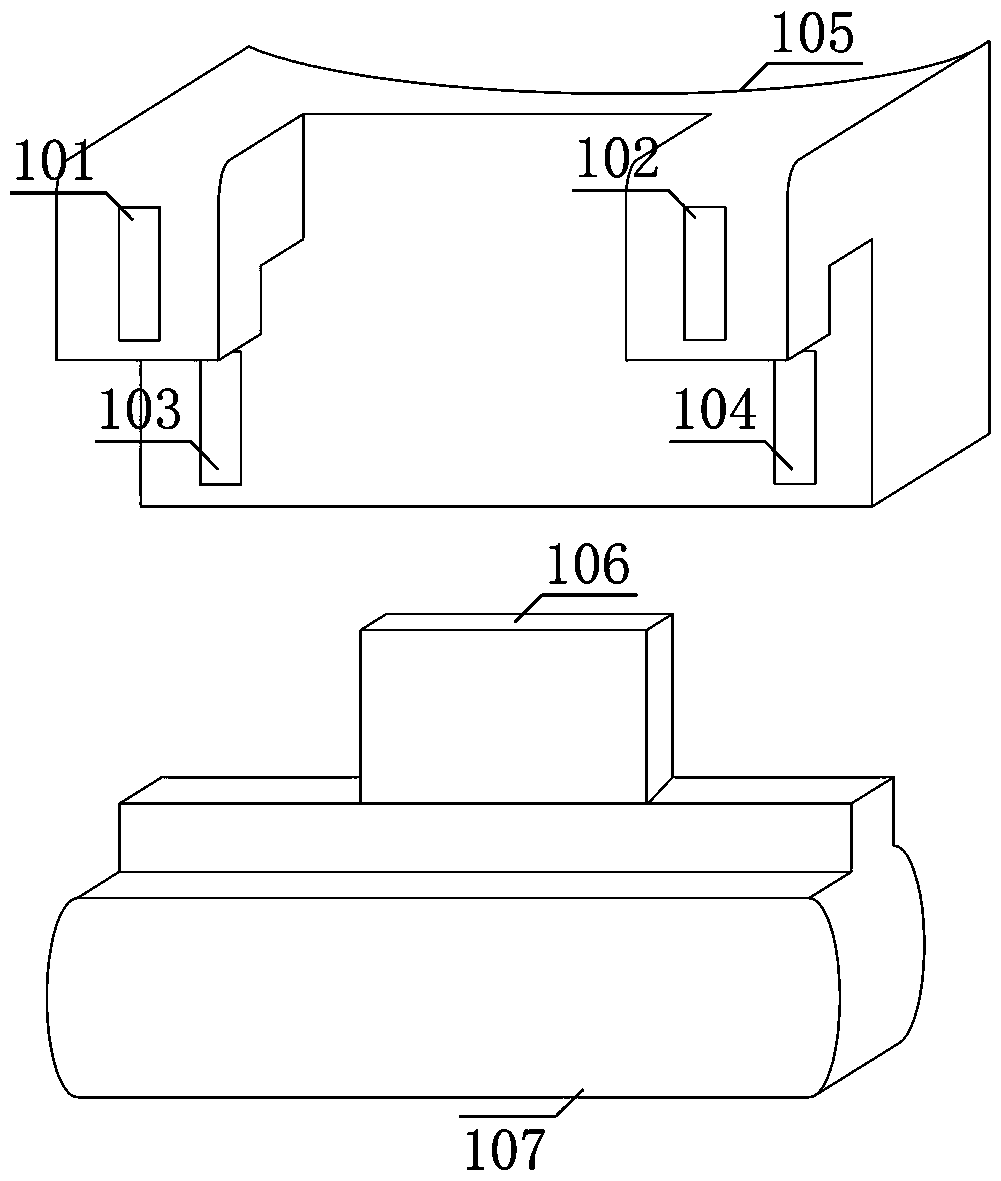

[0066] figure 1 and figure 2 Among them, there are two grooves on the 105 fixed block, the shape of the groove is complementary to the shape of the 107 buckle, and the contact surface between the groove and the 107 buckle is a right-angled surface.

[0067] There are four magnets on the 105 fixed block, respectively 101 first magnets, 102 second magnets, 103 third magnets and 104 fourth magnets, 101 first magnets and 102 second magnets are fixed on 105 Above the fixed block, 101 the first magnetic steel and 102 the second magnetic steel are used to tightly attract the 107 buckle above the 105 fixed block; 103 the third magnetic steel and 104 the fourth magnetic steel are fixed below the 105 fixed block , inside the groove, the 103 third magnetic steel and the 104 fourth magnetic steel are used to tightly attract the 107 buckle under the 105 fixing block, so that the 107 buckle is tightly fixed in the groove.

[0068] There are two magnetic steels on the 107 buckle, the posi...

no. 2 example

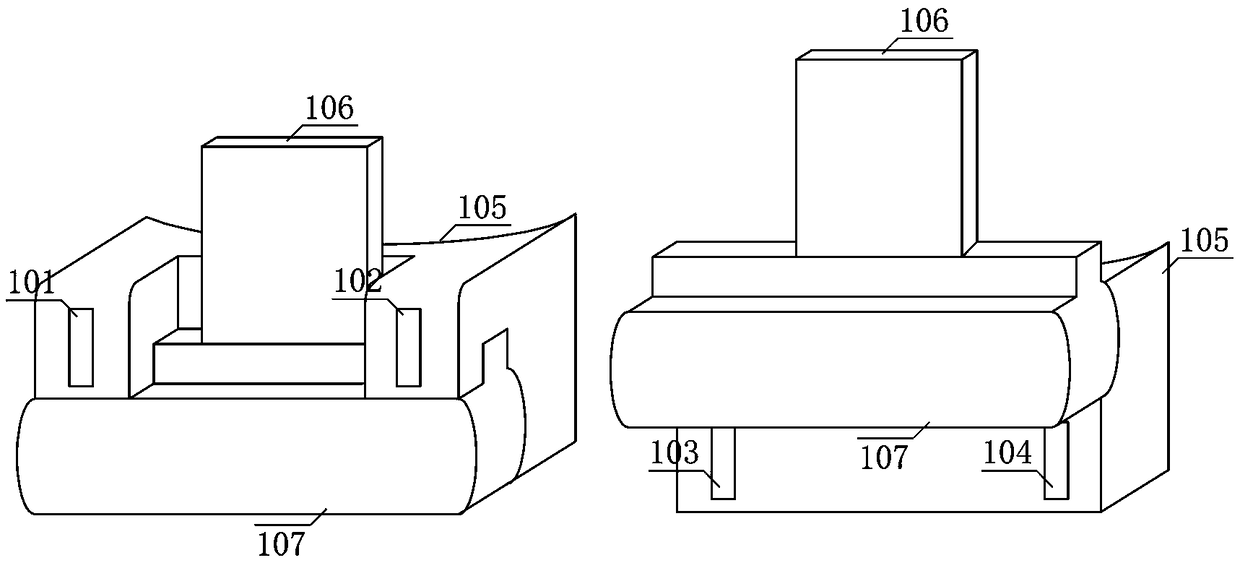

[0071] image 3 and Figure 4 Among them, there are two grooves on the 105 fixed block, the shape of the groove is complementary to the shape of the 107 buckle, and the contact surface between the groove and the 107 buckle is an acute angle surface.

[0072] There are four magnets on the 105 fixed block, respectively 101 first magnets, 102 second magnets, 103 third magnets and 104 fourth magnets, 101 first magnets and 102 second magnets are fixed on 105 Above the fixed block, 101 the first magnetic steel and 102 the second magnetic steel are used to tightly attract the 107 buckle above the 105 fixed block; 103 the third magnetic steel and 104 the fourth magnetic steel are fixed below the 105 fixed block , inside the groove, the 103 third magnetic steel and the 104 fourth magnetic steel are used to tightly attract the 107 buckle under the 105 fixing block, so that the 107 buckle is tightly fixed in the groove.

no. 3 example

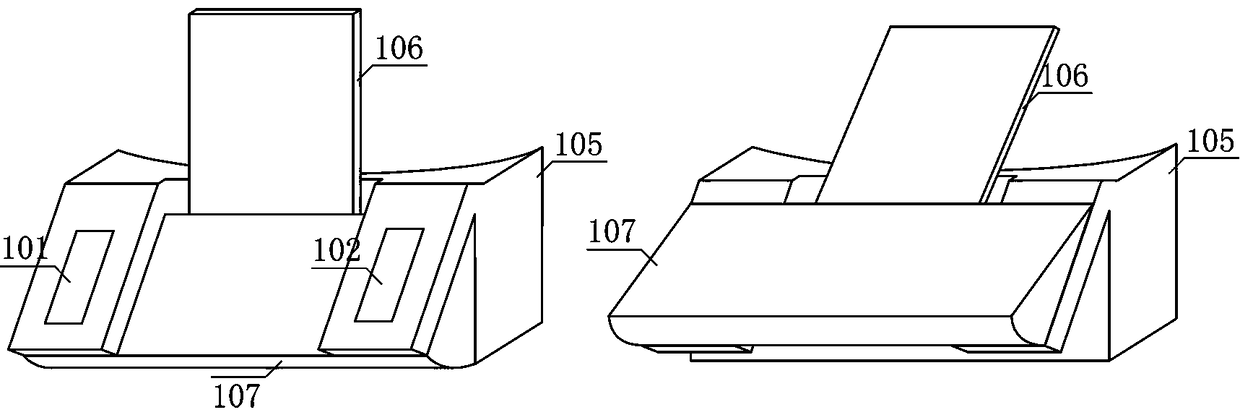

[0074] Figure 5 and Figure 6 Among them, there are four grooves on the 105 fixing block, the shape of the grooves is complementary to that of the 107 buckle, and the contact surface between the grooves and the 107 buckle is a cylindrical surface, which effectively reduces the thickness and volume of the 105 fixing block.

[0075] There are four magnets on the 105 fixed block, respectively 101 first magnets, 102 second magnets, 103 third magnets and 104 fourth magnets, 101 first magnets and 102 second magnets are fixed on 105 Above the fixed block, 101 the first magnetic steel and 102 the second magnetic steel are used to tightly attract the 107 buckle in the groove above the fixed block 105; 103 the third magnetic steel and 104 the fourth magnetic steel are fixed at 105 Below the block, next to the groove, 103 third magnetic steels and 104 fourth magnetic steels are used to closely attract the 107 buckles below the 105 fixed block, so that the 107 buckles are tightly fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com