A kind of tea sorting method

A technology for sorting and tea leaves, which is applied in chemical instruments and methods, solid separation, tea treatment before extraction, etc. It can solve the problems of different processing techniques, increased costs, and uneven defects, so as to improve screening efficiency, Increased running speed and reduced screening loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

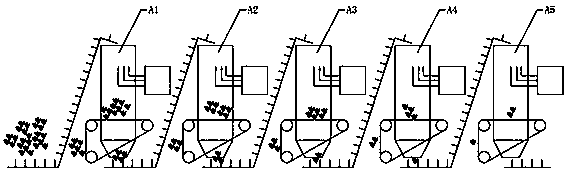

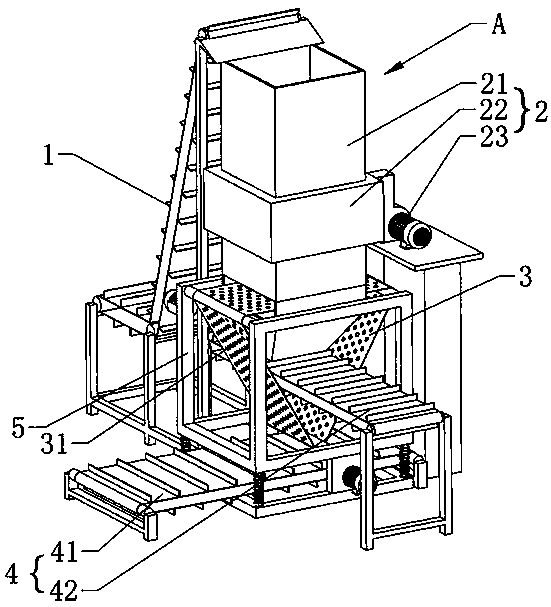

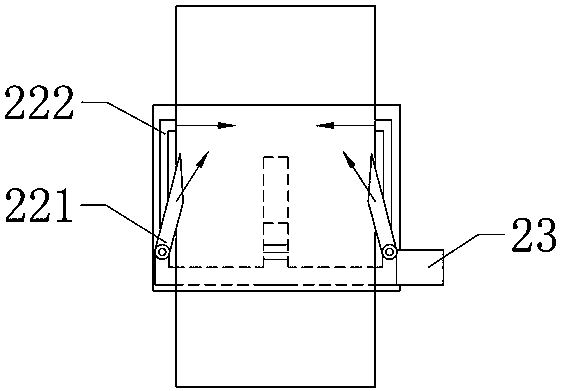

[0033] according to him Figure 1-Figure 5 Shown, a kind of tea sorting method comprises the following steps:

[0034] First, divide the grade of tea: according to the size and appearance of the leaf stem, fresh tea is divided into thick leaf stem, one bud with four leaves, one bud with three leaves, one bud with two leaves, one bud with one leaf, and finely crushed tea according to the size and appearance of the leaf stem. The six grades of leaves and stems;

[0035] Second, set the number of sorting levels: set five graded monomers A for the above six grades, which are the first graded monomer A1, the second graded monomer A2, the third graded monomer A3, and the fourth graded monomer Body A4, the fifth grading monomer A5, wherein, the first grading monomer A1 completes the separation of the thick leaf stem from the one-bud four-leaf and the following size grades, and the second grading monomer A2 completes the one-bud four-leaf and Separation of one bud with three leaves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com