Automatic assembling mechanism of connecting head on water inlet valve

An automatic assembly and connector technology, used in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of reduced assembly speed, affected production efficiency, product quality, etc., to reduce work errors, improve production efficiency and Product quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

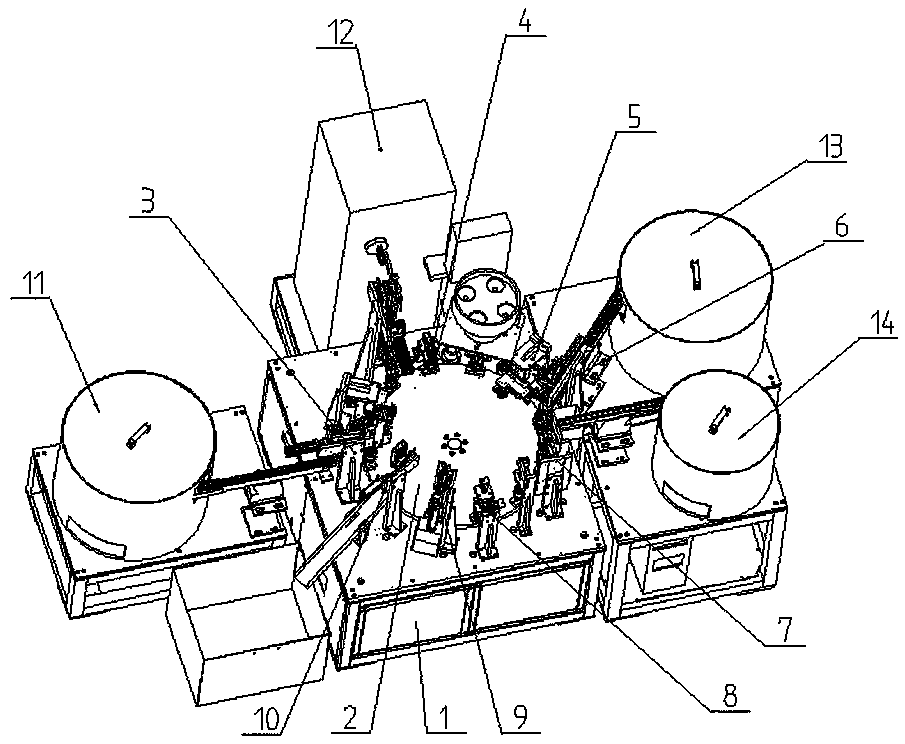

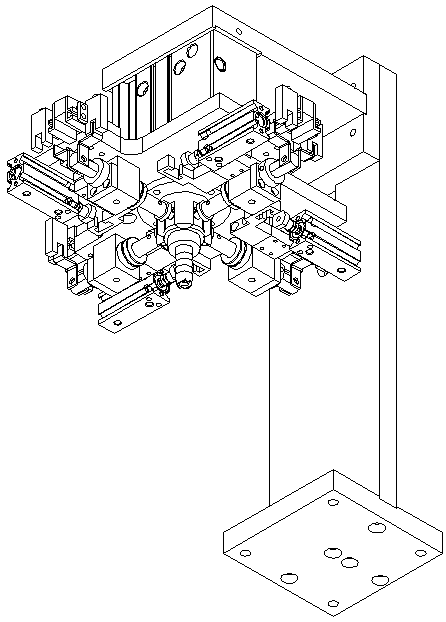

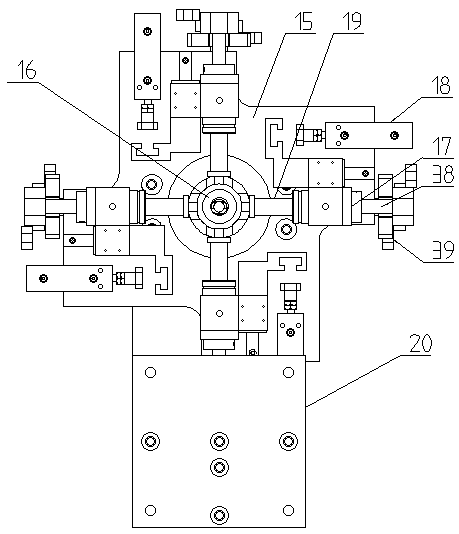

[0025] see Figures 1 to 5In this embodiment, an automatic assembly mechanism for the upper connector of the water inlet valve includes a workbench 1 and a turntable 2 located on the top surface of the workbench 1. The turntable 2 is rotatably connected to the workbench 1 and can rotate horizontally around its center. The turntable 2 On the upper surface and close to the edge, a plurality of clamps for clamping the valve body are evenly spaced along the length of the edge, on the worktable 1 and centered on the center of the turntable 2, a valve core feeding mechanism is arranged at intervals around it 3. Spool hole detection mechanism, spring assembly mechanism, spring detection mechanism 4, steel ball assembly mechanism, steel ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com