Cable extrusion die

A technology for extruding molds and cables, which is applied in the direction of coating, etc., can solve the problems of poor versatility and inability to meet the multi-purpose of one mold, and achieve the effects of improving versatility, facilitating R&D and debugging, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

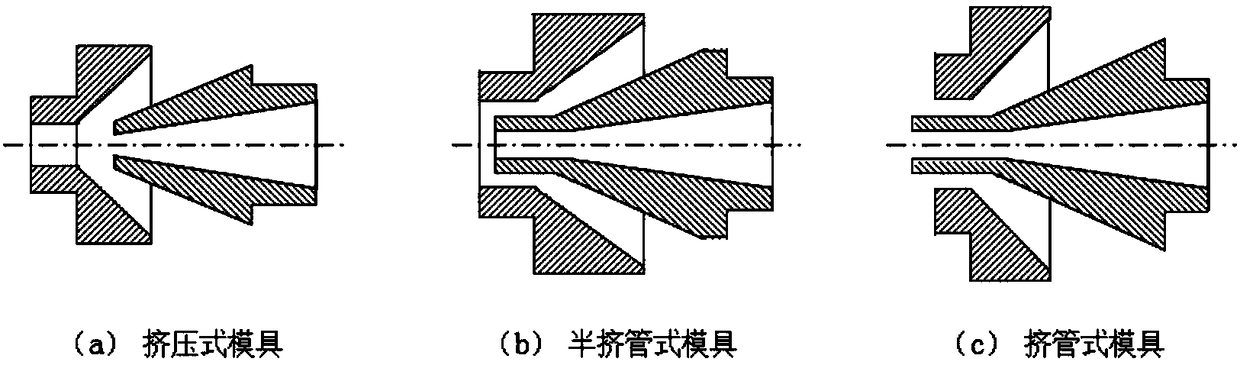

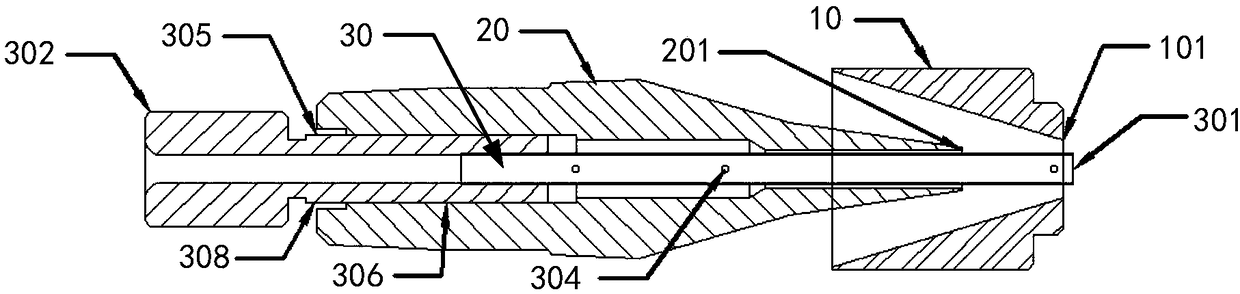

[0022] figure 2 A schematic structural view of a cable extrusion die proposed by a preferred embodiment of the present invention is shown. The cable extrusion die proposed in this embodiment can realize the conversion of three types of extrusion dies: extrusion type, extruded tube type, and semi-extruded tube type by adjusting the position of the needle tube body in the inner mold, so as to be suitable for different cable extrusion dies. Extrusion process for shapes and materials. The mold integrates three types of extrusion molds, which can be flexibly converted and quantized and fine-tuned, which is convenient for cable research and development and debugging. One mold can be used for multiple purposes, which improves the versatility of cable extrusion molds and reduces production costs. .

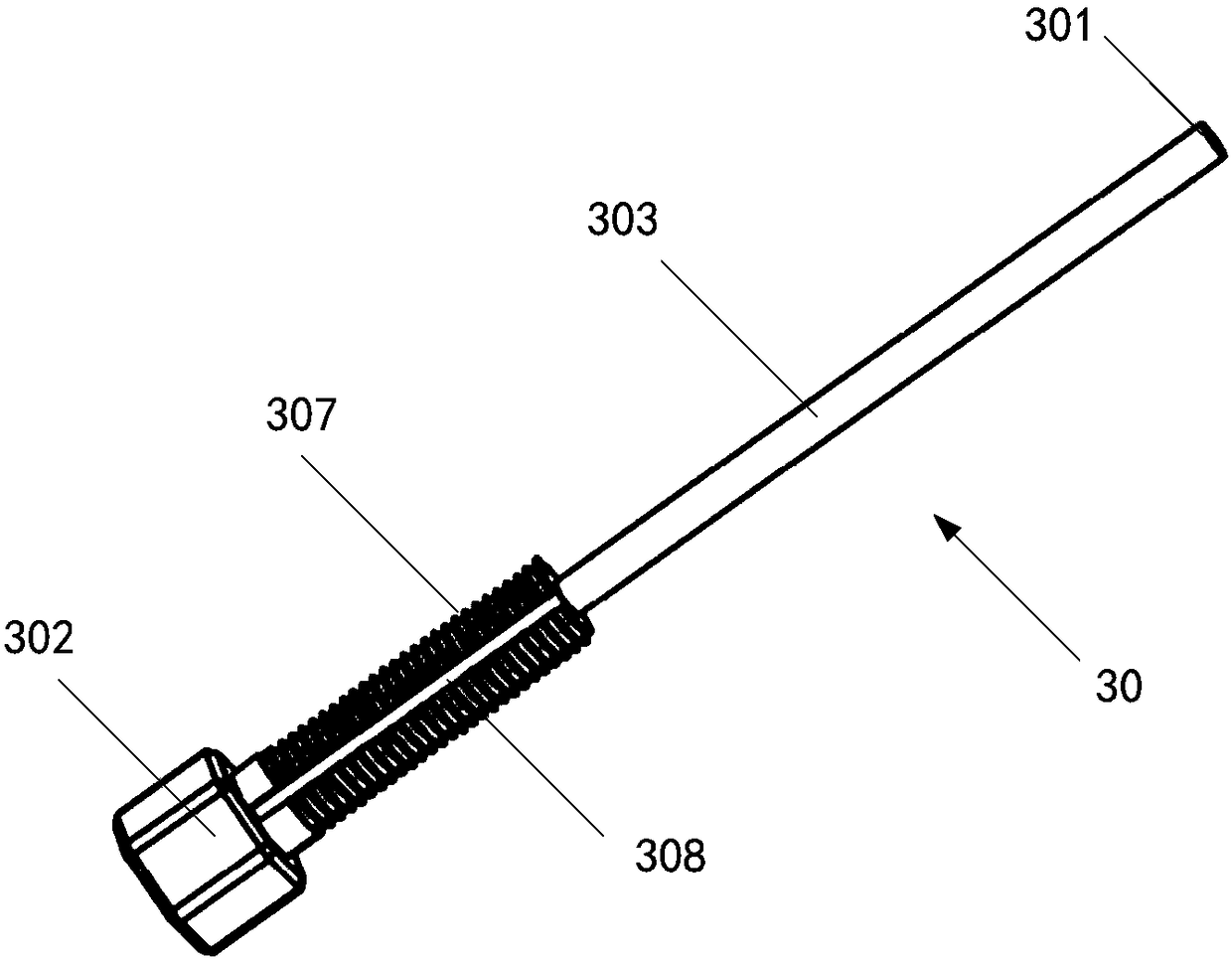

[0023] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com