Continuous fiber winding station for large-diameter PE fiber-reinforced pipe

A continuous fiber and fiber reinforced technology is applied in the field of continuous fiber tape winding reinforced pipe production, which can solve the problems of increasing the wall thickness of the pipe, and achieve the effects of improving the compressive strength, reducing the cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

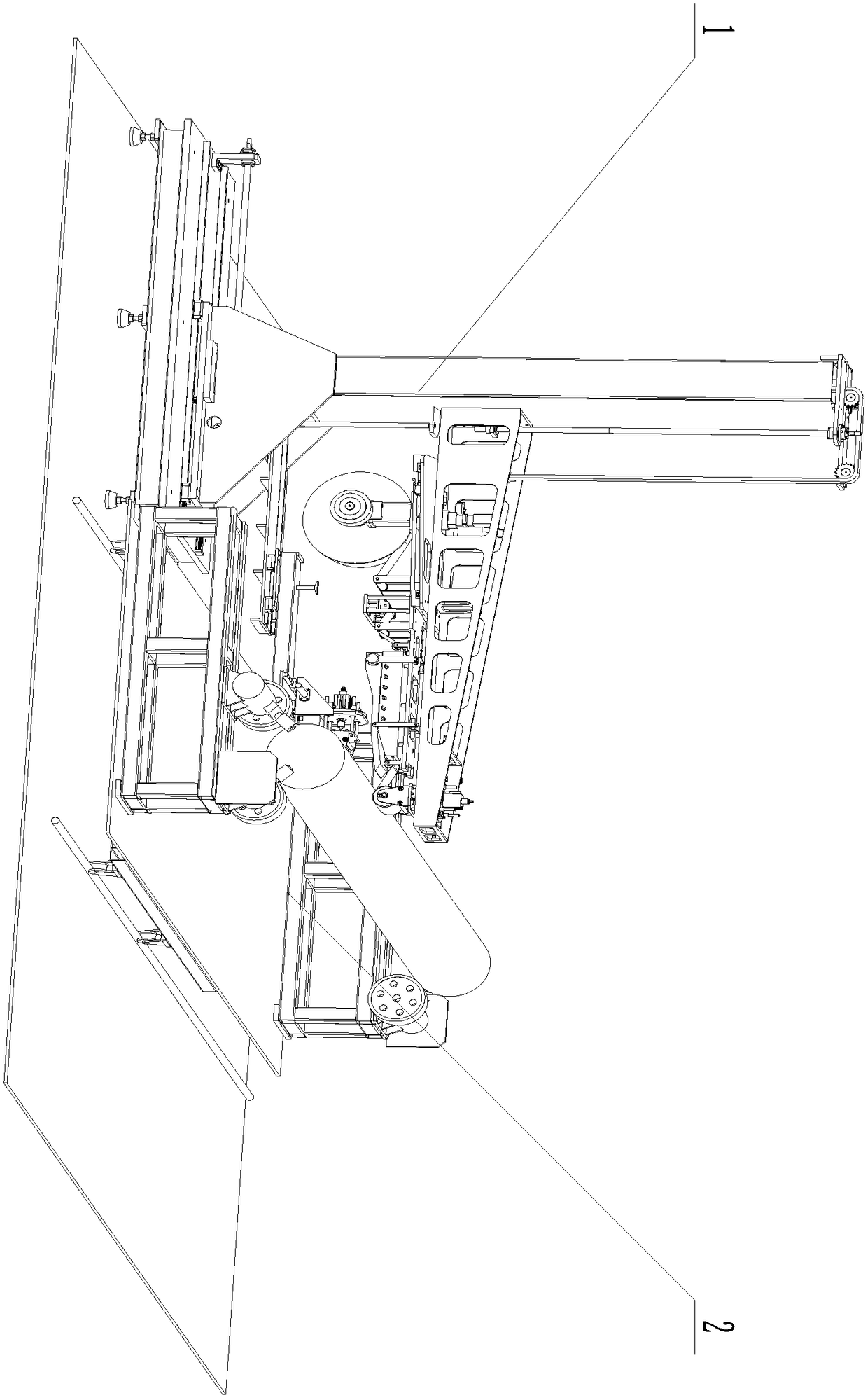

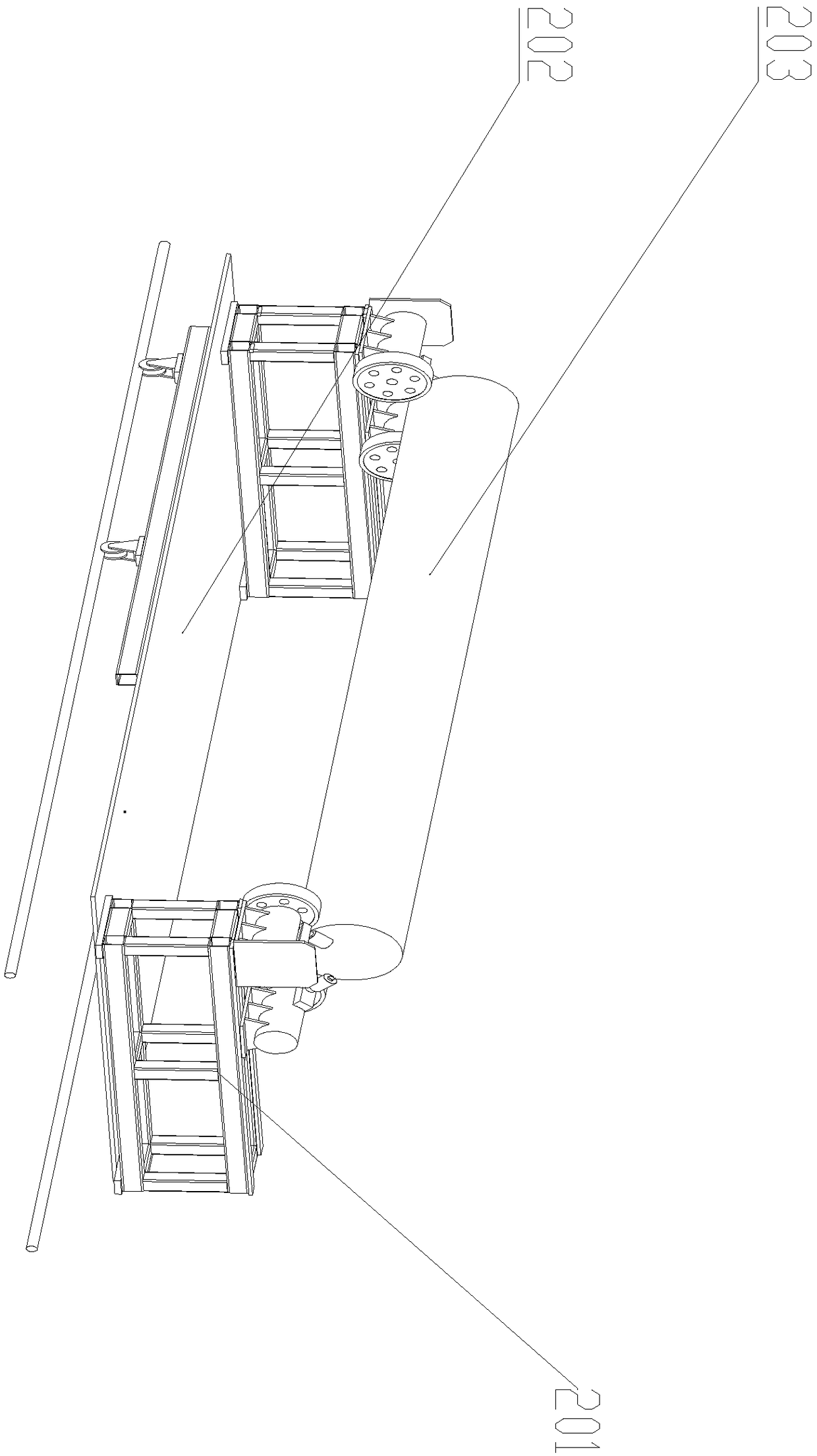

[0011] 1. see figure 1 , with reference to figure 2 , image 3 , a continuous fiber winding station for PE large-diameter fiber-reinforced pipes provided by the present invention, the feeding mechanism on the pipe vertical fiber winding machine 1 rolls the continuous fibers, and the pipe mold rotary carrier 2 drives the mold to rotate, so that The mold rotates clockwise, so that the feeding mechanism of the vertical fiber winding machine 1 can transport continuous fibers. The compressive strength is greatly improved.

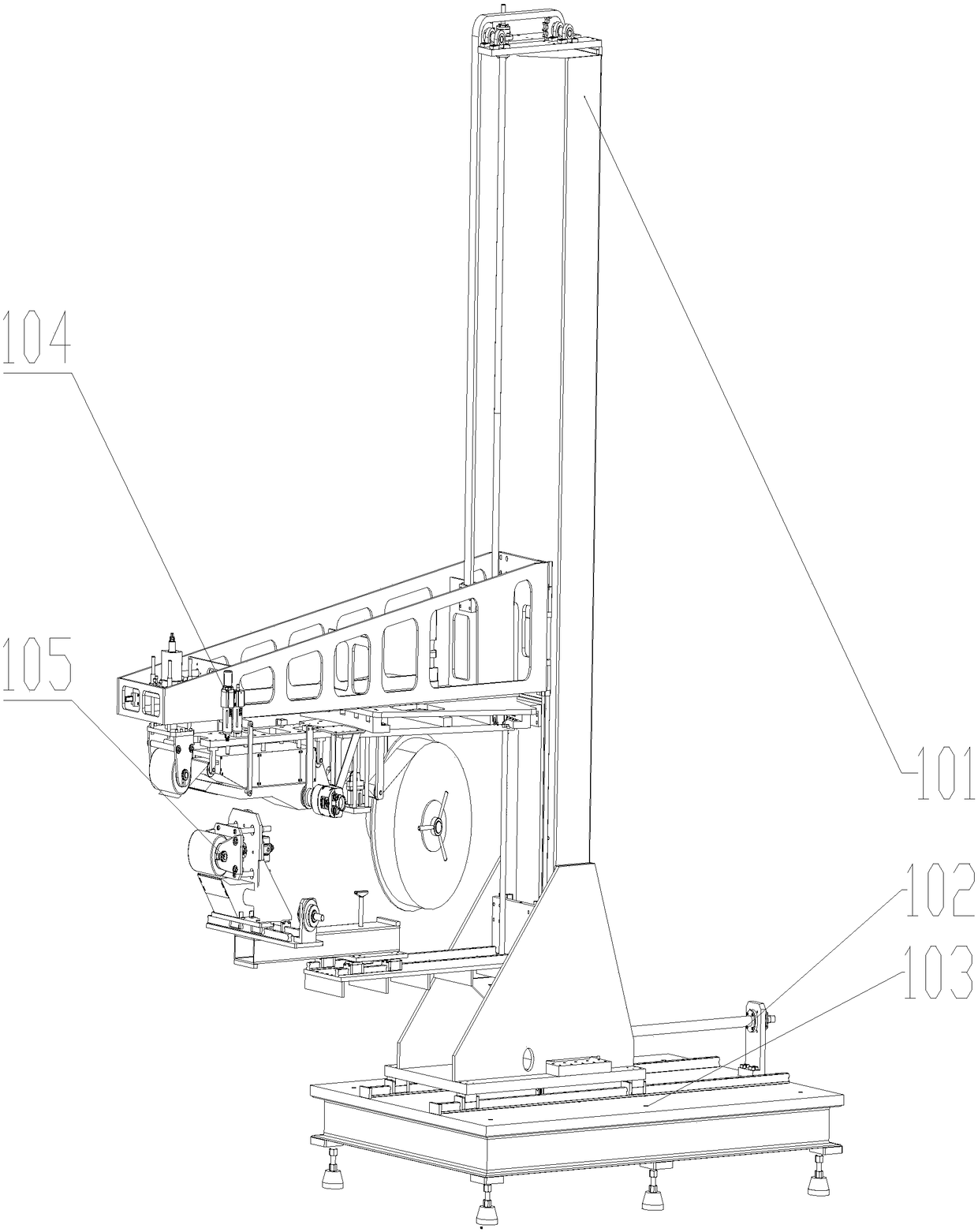

[0012] 2. see figure 2 , the continuous fiber is wound onto the continuous fiber lifting and conveying platform 104 structure in the vertical fiber winding machine 1, and the secondary rolling 105 structure in the vertical magenta winding machine 1 adjusts the front and rear distances to the continuous fiber wound on the pipe mold For secondary rolling, the continuous fiber lifting and conveying platform 104 structure in the vertical fiber winding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com