Barrel frame support type steel platform and tower crane integral jacking device and jacking method thereof

A technology of integral jacking and steel platform, applied in construction, crane, building structure, etc., can solve problems such as easy conflict, achieve the effect of saving construction cost, enhancing overall safety, and reducing the difficulty of coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

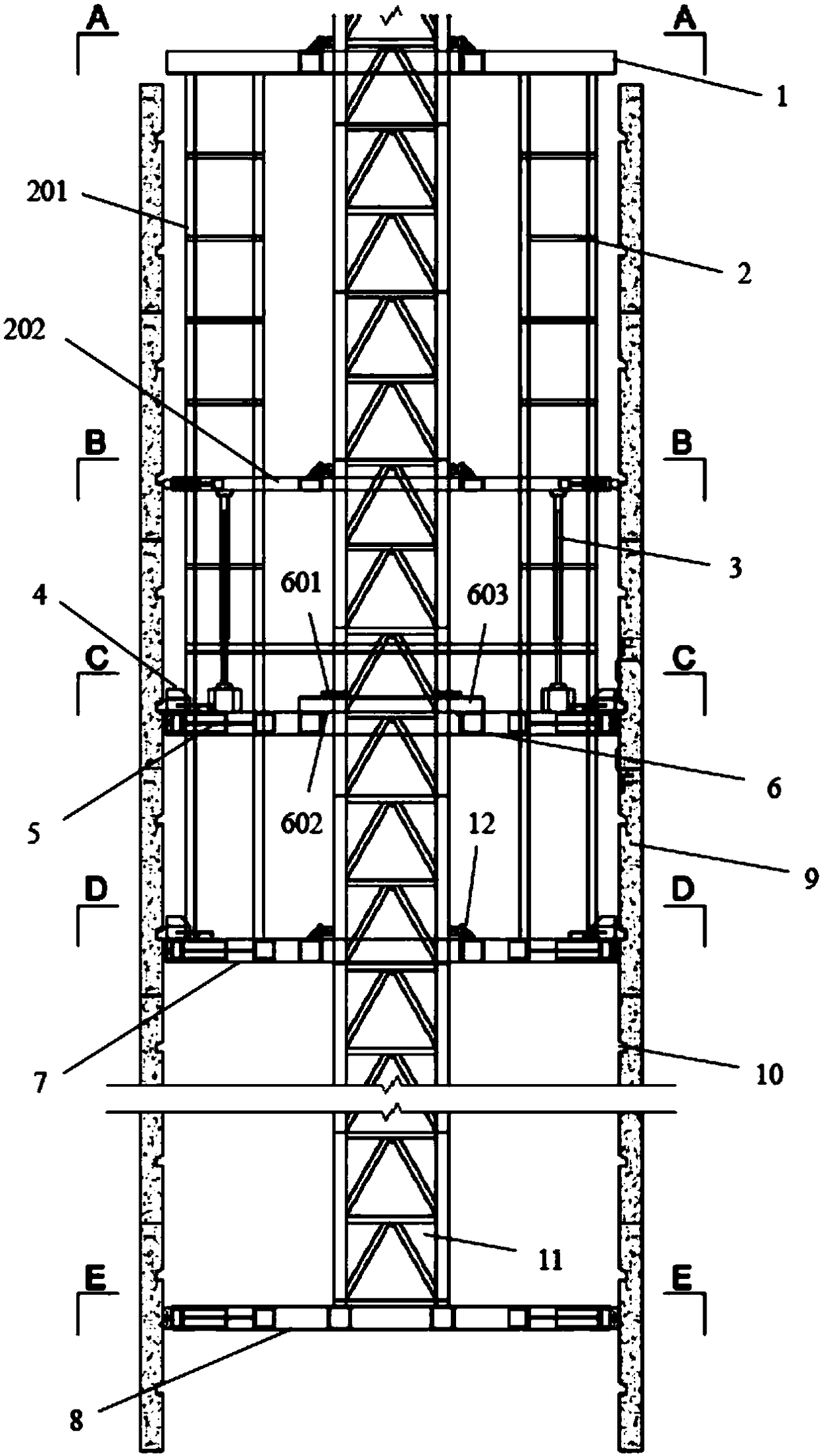

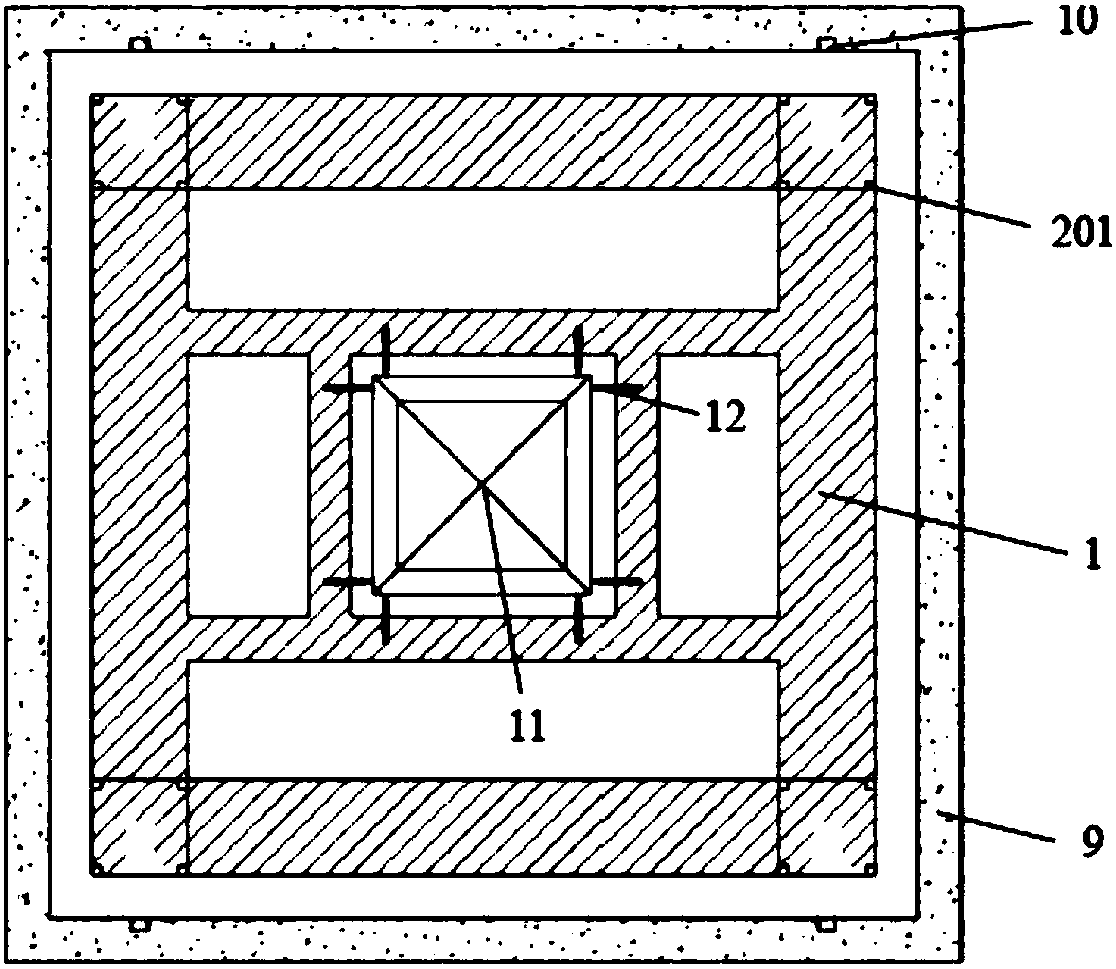

[0066] A cylinder frame supported steel platform and a tower crane integral jacking device, comprising a cylinder frame supported steel platform, a tower crane and a jacking power system; the steel platform comprises a steel platform top beam 1, a cylinder frame support 2, an integral jacking up Beam 6, integral jacking lower beam 7 and tower crane support beam 8; cylinder frame support 2 includes cylinder frame support column 201 and reaction beam 202, the reaction beam is preferably an oil cylinder reaction beam; the steel platform top beam 1, oil cylinder The reaction force beam 202, the overall jacking upper beam 6, the overall jacking lower beam 7 and the tower crane support beam 8 are arranged in sequence from top to bottom; the steel platform top beam and the reaction force beam are provided with horizontal limit guide wheels 12, so The guide wheel can selectively resist the tower crane; the bottom of the tower crane is fixedly connected with the tower crane support beam...

Embodiment 2

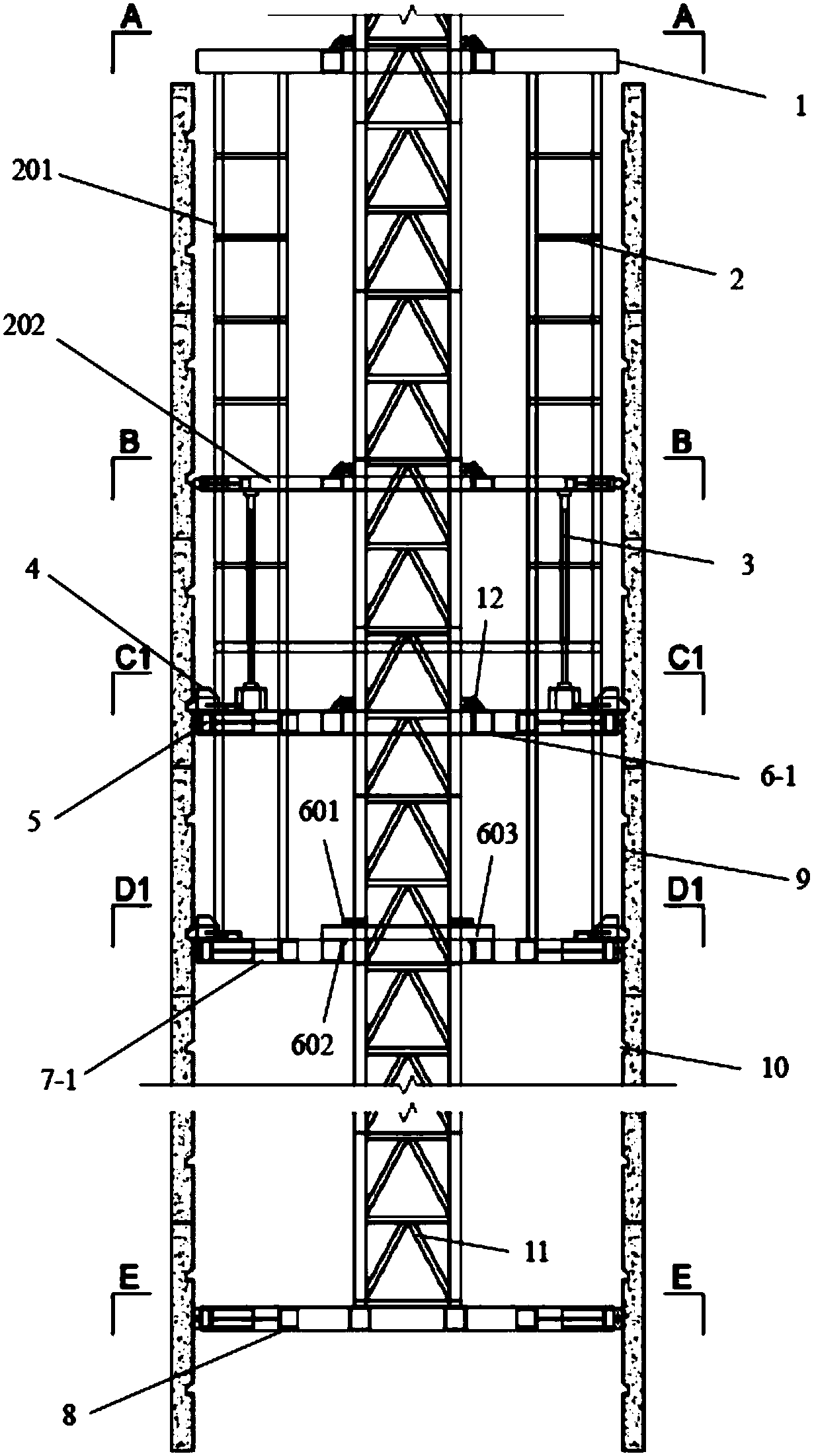

[0084] like figure 2 As shown in the figure, this embodiment provides a synchronous jacking device. The difference from Embodiment 1 is that in this embodiment, the lower beam for integral jacking and the tower crane are connected, and the upper beam for integral jacking is provided with a horizontal limiter. The guide wheel is positioned to selectively abut the tower crane. The jacking process of the synchronous jacking device is as follows: Figure 17-20 , Figure 17 is the initial state, at this time it is the state of preparation for jacking; Figure 18 The cylinder is in the jacking state. At this time, the hydraulic cylinder drives the cylinder reaction beam to lift, and the cylinder reaction beam drives the steel platform and the tower crane to lift; Figure 19 The cylinder is in the state of lifting back, at this time the hydraulic cylinder drives the overall lifting of the upper beam to lift; Figure 20 It is in the state of completion of lifting.

[0085] The h...

Embodiment 3

[0089] like Figure 13-16 As shown, this embodiment provides an asynchronous jacking method using the above-mentioned integral jacking device, and the method can be decomposed into an initial state, the oil cylinder is lifted, the oil cylinder is lifted back, and the jacking is completed.

[0090] The asynchronous jacking method specifically includes the following steps:

[0091] Step 1: Initial state, complete the preparations before jacking;

[0092] Step 2: In the jacking state, the overall jacking beam bears the vertical load, the jacking power system provides power, and the reaction beam drives the steel platform to jack up in place;

[0093] Step 3: In the lifting state, the jacking power system provides power to drive the overall jacking of the lower beam and the tower ceiling to lift into place;

[0094] Step 4: The jacking is completed.

[0095] Preferably, the step 1 includes: checking whether each component has the lifting conditions, ensuring that the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com