Preparation method of cross-linked sulfonated polyarylether proton exchange membrane

A technology of proton exchange membrane and sulfonated polyarylene ether, which is applied in the field of preparation of cross-linked sulfonated polyarylene ether proton exchange membrane, can solve the problems of proton conductivity and anti-oxidative stability decrease, etc., and is conducive to proton transfer. , the synthesis process is simple, the effect of good dimensional stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

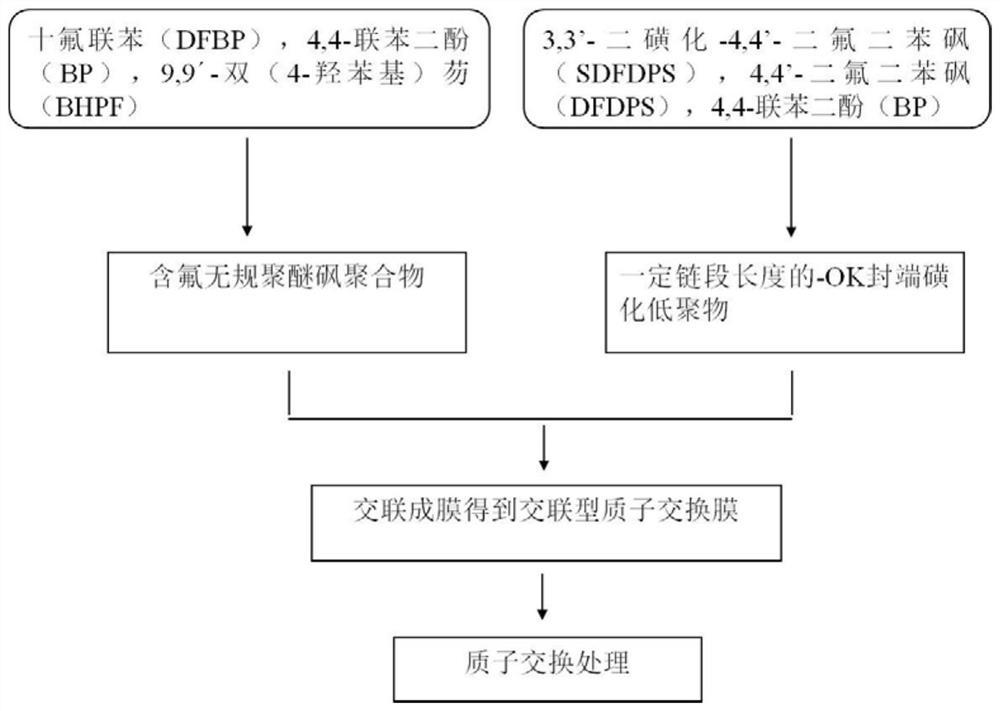

[0025] The preparation process of the cross-linked proton exchange membrane of the present invention is as follows: figure 1 , using BP, BHPF, DFBP and SDFDPS, DFDPS, BP as raw materials to prepare fluorine-containing polyarylether polymers and sulfonated polyarylether oligomers through nucleophilic polycondensation reactions, and then using sulfonated oligomers as crosslinking agents Thermal cross-linking reaction with fluorine-containing polymer to prepare cross-linked sulfonated polyarylether proton exchange membrane. Its preparation steps are as follows:

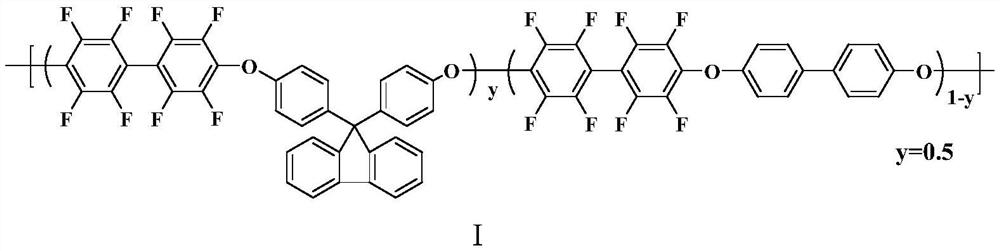

[0026] Step 1, preparation of fluorine-containing random polymer

[0027] Dissolve decafluorobiphenyl (DFBP), 4,4-biphenol (BP), 9,9'-bis(4-hydroxyphenyl)fluorene (BHPF) in N,N-dimethylacetamide ( DMA C ) to form a solution with a solid-to-liquid ratio of 20% to 25%, and add 1.2 to 1.5 times the K relative to the number of hydroxyl moles 2 CO 3 As a catalyst, cyclohexane is used as an azeotropic water-carrying agent...

Embodiment 1

[0038] Preparation of embodiment 1 fluorine-containing random polymer

[0039] In a three-necked flask equipped with a nitrogen gas guiding device, an oil-water separator and a condenser tube, 0.876g (2.5mmol) 9,9'-bis(4-hydroxyphenyl)fluorene (BHPF), 0.464g (2.5mmol) ) 4'4-dihydroxybiphenyl (BP), 1.670g (5mmol) decafluorobiphenyl (DFBP) and 12mL DMAc, after the drug was completely dissolved, add 0.829g (6.00mmol) anhydrous potassium carbonate (K 2 CO 3 ), 10mL cyclohexane, slowly heated up to 90°C for 10h under nitrogen protection, cooled naturally to room temperature, poured the reactant into deionized water to precipitate a white fibrous solid, washed several times with deionized water and ultrasonically placed at 105 °C in a vacuum oven for 24 hours to obtain a fluorine-containing random polymer main chain.

Embodiment 2

[0041] This example is basically the same as Example 1, except that the reaction temperature is 85° C., and the fluorine-containing random polymer is prepared after 12 hours of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com