Rectifying cover for wind-powered generator

A technology of fairings and wind turbines, which is applied to wind engines, engines, and wind power generation. It can solve problems such as damage to wind turbines, poor shock absorption performance, and rectifier collisions, and achieve good safety and good shock absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

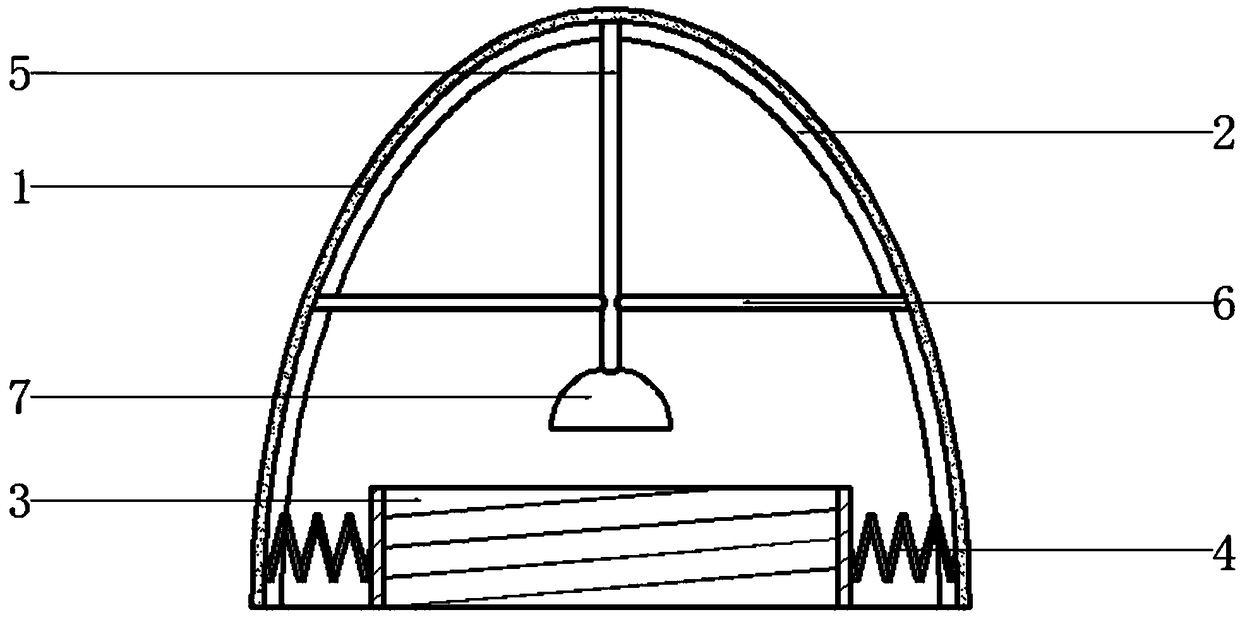

[0016] combine figure 1 with figure 2 , the wind turbine fairing includes a semi-elliptical casing 1, the inner wall of the casing 1 is provided with a layer of flexible inner pad 2, the opening of the casing 1 is provided with a circular tube-shaped threaded cylinder 3, and the inner wall of the threaded cylinder 3 is tapped with a concave Screw thread, the outer wall of the threaded cylinder 3 is vertically connected with the inner wall of the casing 1 through four evenly distributed damping springs 4, and the inside of the casing 1 is provided with a cylindrical support rod 5, which is coaxial with the threaded cylinder 3, and the support rod 5 The end is vertically provided with a hemispherical shell-shaped suction bowl 7 , and the side of the support rod 5 is vertically provided with several push rods 6 connected with the inner wall of the casing 1 .

[0017] The casing 1, the supporting rod 5 and the ejector rod 6 are all made of stainless steel, which is durable, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com