Magnetic field probe adopting isolation via-hole structure

A magnetic field probe and via technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of weak signal current, errors, and inability to test and measure, and achieve the effect of improving the defects of measurement errors and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The practice of the present invention will be further described in detail below in conjunction with the accompanying drawings.

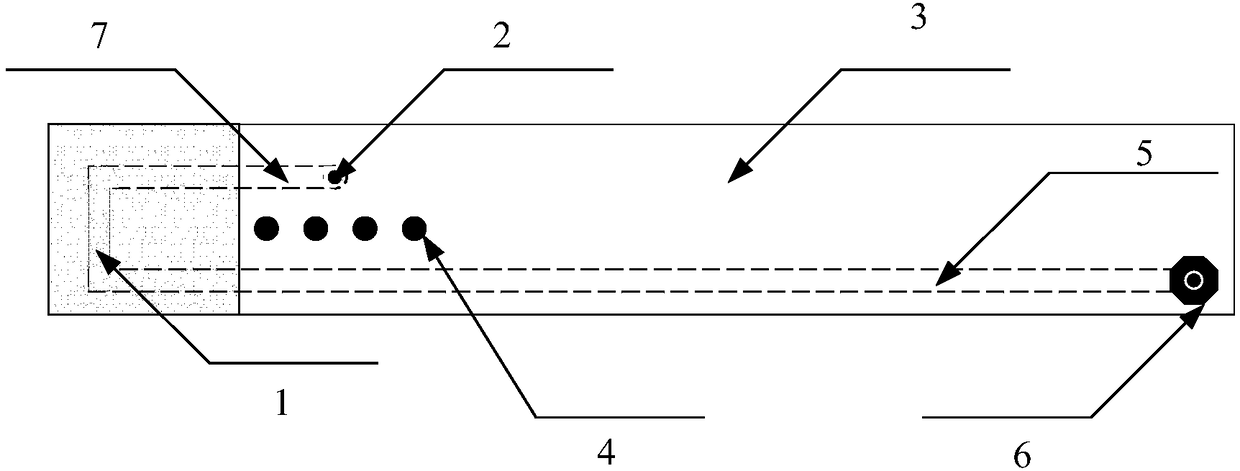

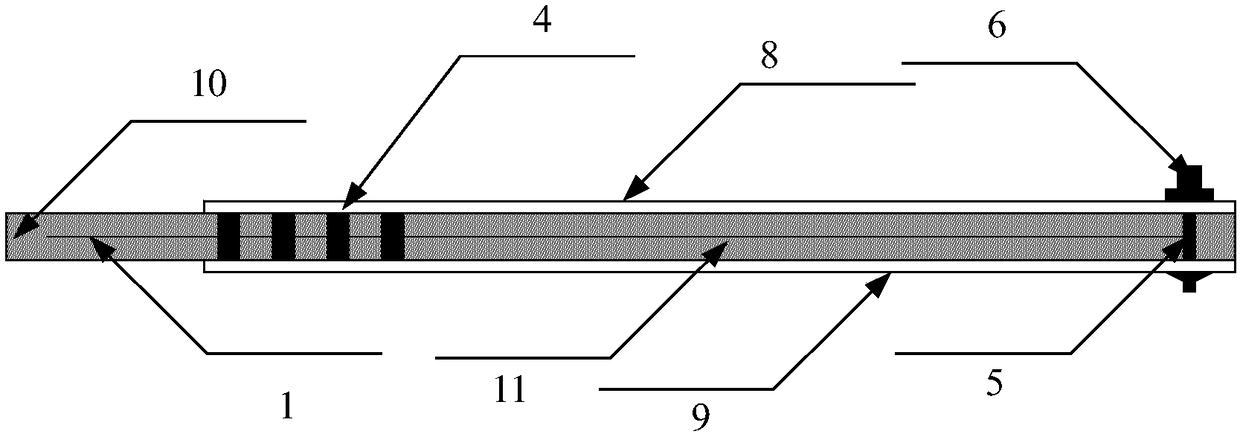

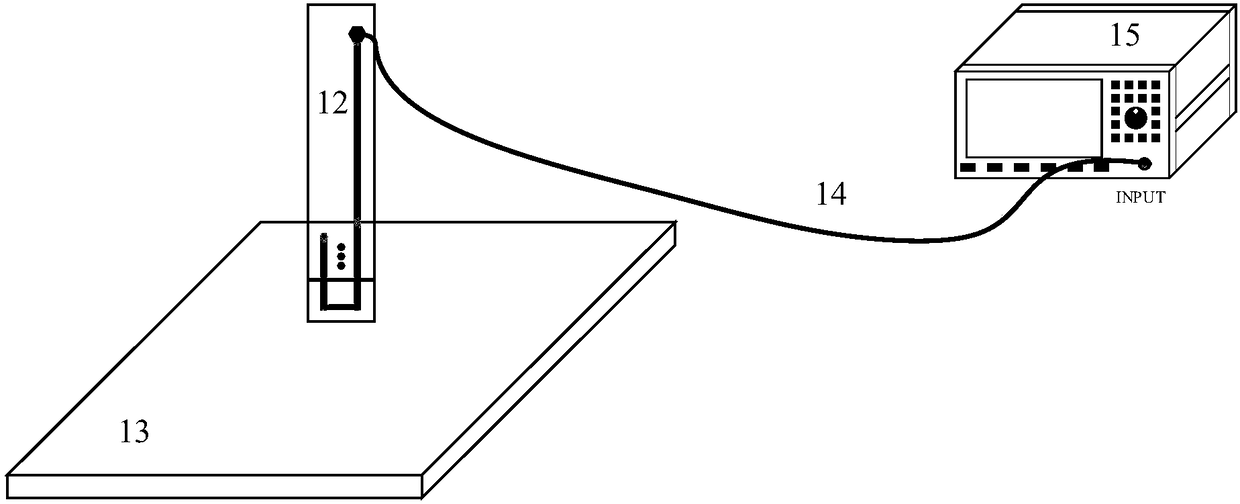

[0019] Such as figure 1 figure 2 As shown, this embodiment provides a magnetic field probe for near-field testing, including a symmetrical unshielded ring 1, a ground via 2, a strip line 3, an isolation via 4, a signal via 5, an adapter 6, Unshielded ring symmetrical arm extension line 7 , stripline shielding layer 8 , stripline lower shielding layer 9 , stripline medium 10 and stripline signal line 11 . The symmetrical unshielded ring 1 is located in the interlayer of the dielectric material 10 of the stripline 3 to ensure the strength of the symmetrical unshielded ring, one arm of the ring is directly connected to the signal line 11 of the stripline 3, and the other arm After the unshielded symmetrical ring extension line 7 is connected to the upper shielding layer 8 and the lower shielding layer 9 of the stripline 3 through the grounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com