Volatile organic compound recycling system

A volatile organic compound, recovery and treatment technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as equipment aging that cannot be detected in time, vacancies in environmental protection equipment supervision, environmental damage, etc., to achieve reasonable design and timely adjustment. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with specific examples.

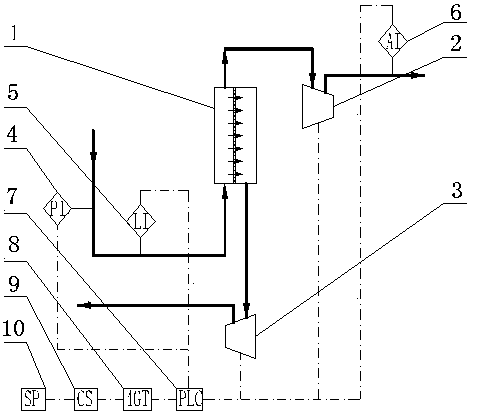

[0015] Such as figure 1 As shown, the volatile organic compound recovery treatment system includes a membrane separator 1, the non-permeable gas outlet of the membrane separator 1 is connected to the inlet of the exhaust pump 2; the permeation outlet of the membrane separator 1 is connected to the inlet of the vacuum pump 3; the inlet of the membrane separator 1 is connected to the pressure sensor 4. The inlet of the membrane separator 1 is connected to the liquid level sensor 5; the outlet of the exhaust pump 2 is connected to the online analyzer 6; the signal of the exhaust pump 2 is connected to the PLC display control module 7; the signal of the vacuum pump 3 is connected to the PLC display control module 7; the signal of the pressure sensor 4 Connect to the PLC display control module 7; the signal of the liquid level sensor 5 is connected to the PLC display control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com