A modular motor stator structure

A motor stator, modular technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electromechanical devices, etc., can solve the problem of inability to greatly reduce end loss and temperature, inconvenient motor maintenance, Transformation, time-consuming and other issues to achieve the effect of ensuring control flexibility and controllability, improving fault tolerance and reliability, and reducing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

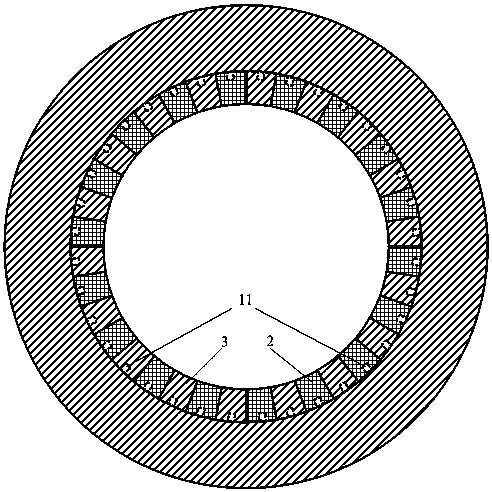

[0032] The following is attached Figure 1 to Figure 7 The specific implementation manner of this embodiment will be described in detail.

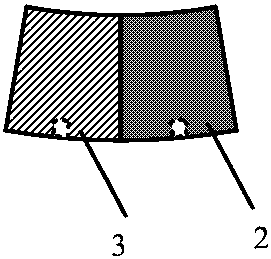

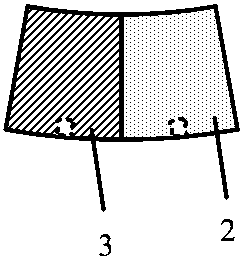

[0033] A modularized motor stator structure of the present invention includes a stator, the inner ring of the stator yoke 1 is evenly arranged with a plurality of protrusion groups along the circumferential direction, and each protrusion group includes a plurality of radially inward protrusions protruding from the stator The inner ring of the yoke 1 is provided with a protrusion 11 arranged in the axial direction; the inner ring of the stator yoke 1 is also provided with a magnetic strip 2 and a stator tooth 3 alternately along the circumferential direction, and the magnetic strip 2 and the stator tooth 3 are connected with the The protruding groups are arranged correspondingly, and the magnetic strip 2 and the stator tooth part 3 are provided with a groove matching the corresponding convex part 11, and the magnetic conductive strip 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com