High-precision crank press for realizing flexible processing

A crank press and flexible processing technology, which is applied in the field of presses, can solve problems such as uncontrollable and unadjustable, and achieve the effects of saving energy consumption, improving production efficiency, and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

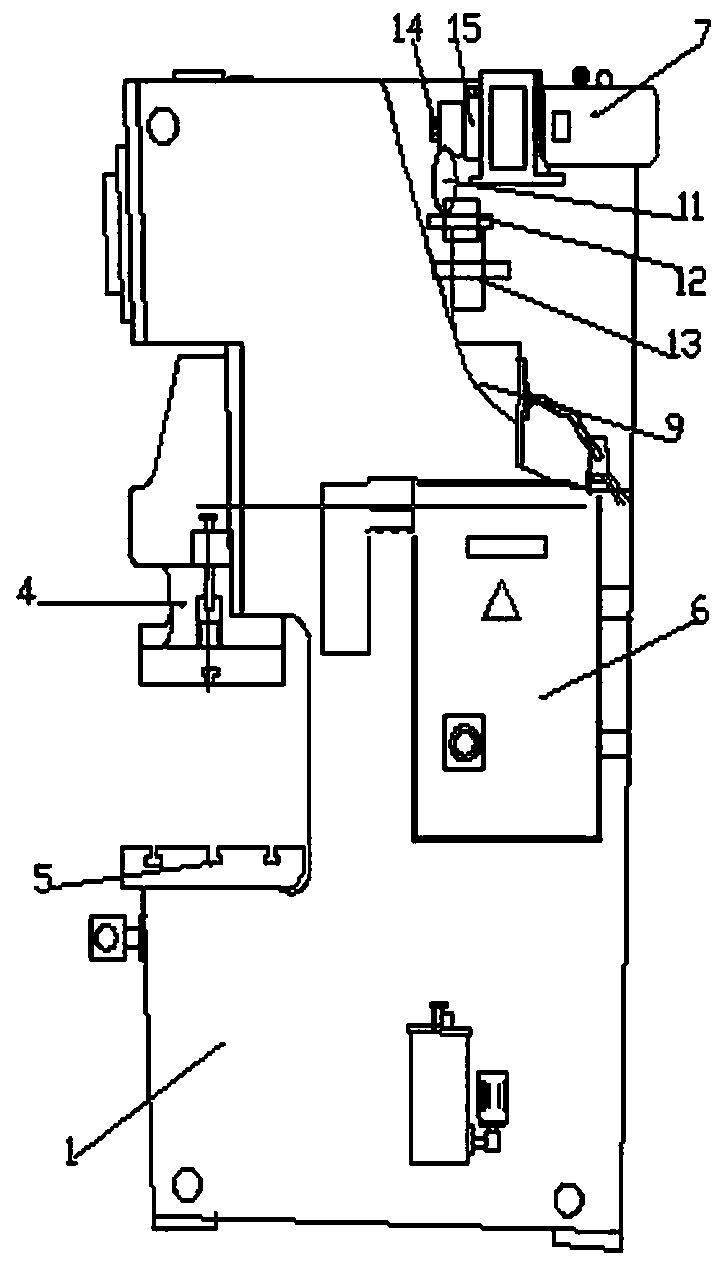

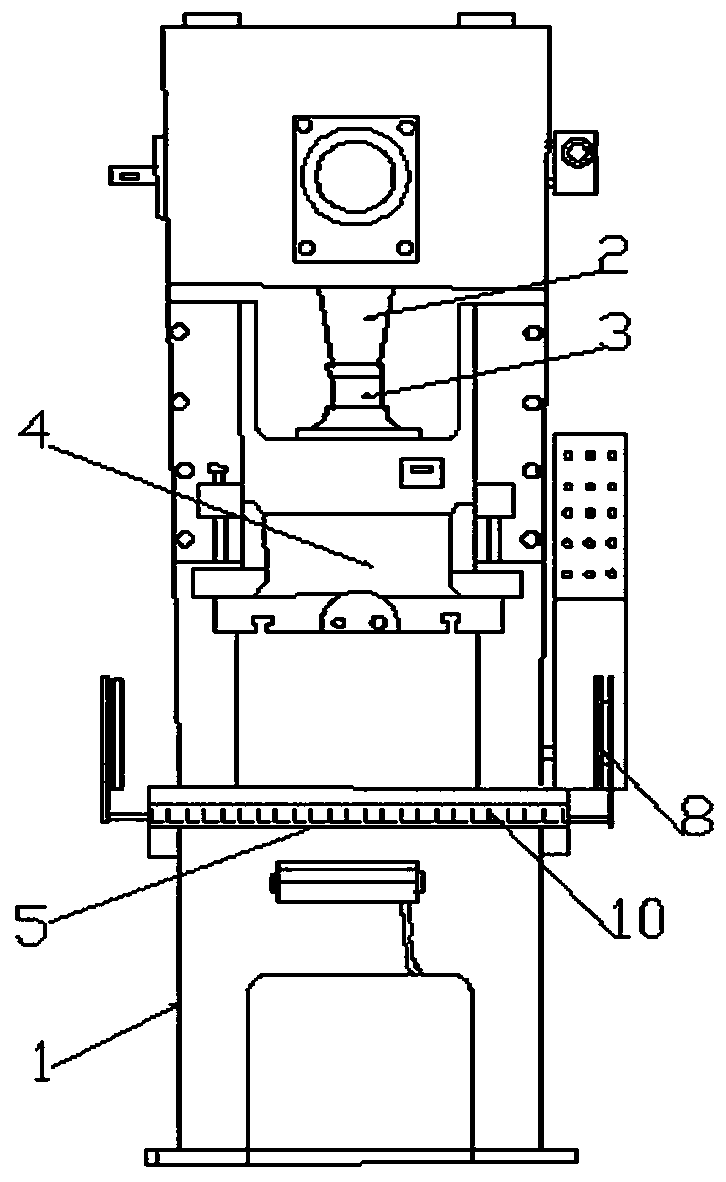

[0013] Such as Figure 1-2 As shown, a high-precision crank press that can realize flexible processing includes a body 1, a transmission mechanism, a control system, and an electrical cabinet 6. The transmission mechanism includes a switched reluctance motor 7, a flywheel 11, a gear shaft 12, and a large gear 13. , crankshaft 2 and connecting rod 3, one end of the switched reluctance motor 7 is connected to the control system and the electrical cabinet 6, and one end is connected to the flywheel 11, the flywheel 11 is connected to the gear shaft 12, the gear shaft 12 is connected to the bull gear 13, and the bull gear 13 is connected to the crankshaft 2, One end of the crankshaft 2 is connected to the connecting rod 3, and the connecting rod 3 is hinged to the slide block 4; the switched reluctance motor 7 includes a stator, a rotor 15 and a rotating shaft 14, and one side of the rotor 15 is connected to the fuselage, and the rotating shaft 14 is provided with a draw-in groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com