Stirring paddle for desulfuration

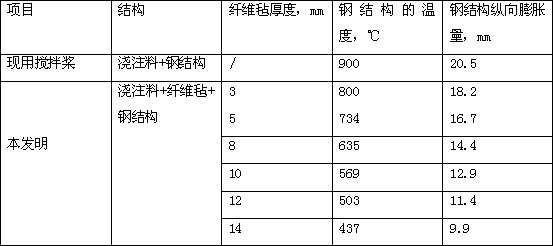

The technology of stirring paddle and metal skeleton is applied in the field of molten iron desulfurization, which can solve the problems of large expansion and high temperature of steel structure, and achieve the effects of reducing expansion, improving service life and reducing the possibility of cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

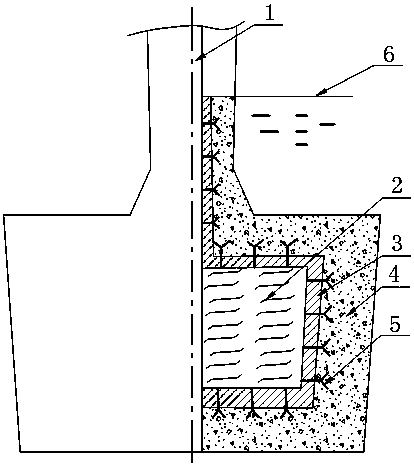

[0023] like figure 1 , a stirring paddle for desulfurization, including a metal skeleton and a castable layer 4, the surface of the metal skeleton is provided with a number of anchors 5 at intervals, in this embodiment, preferably, the anchors 5 are arranged at equal intervals; A layer of inorganic non-metallic heat-insulating fiber layer 3 is also arranged between the metal skeleton and the castable layer 4, and the thickness of the fiber mat 3 is 5-15mm; in the present invention, as a preference, the metal skeleton includes a central axis steel structure 1 and blade steel structure 2, the castable layer 4 is mullite castable.

[0024] The stirring paddle manufacturing process of the present invention is as follows:

[0025] 1) The anchors 5 are welded on the surface of the metal skeleton. In this embodiment, as a preference, the distance between two adjacent anchors 5 is 100-120 mm. This increased distance between the anchors not only reduces the The expansion itself is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com