Pre-stressed assembling structure and construction method of prefabricated concrete duct pieces for well-sinking type bridge substructure

A technology of prefabricated concrete and construction method, which is applied in the direction of infrastructure engineering, bridges, bridge construction, etc., can solve problems such as long construction period, difficulty in ensuring structural quality, difficulty in transportation and installation, etc., to improve project quality, strong project adaptability, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

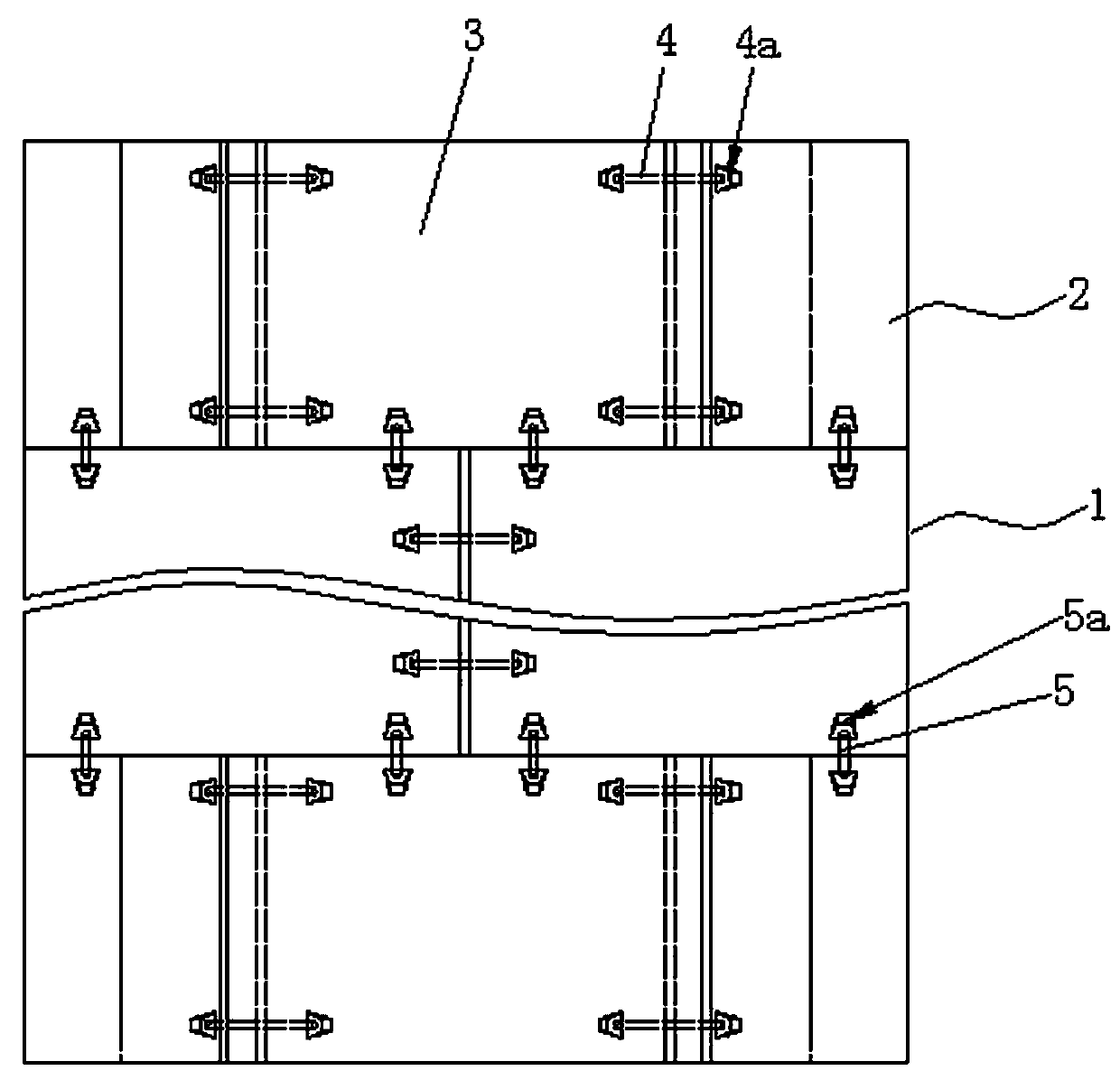

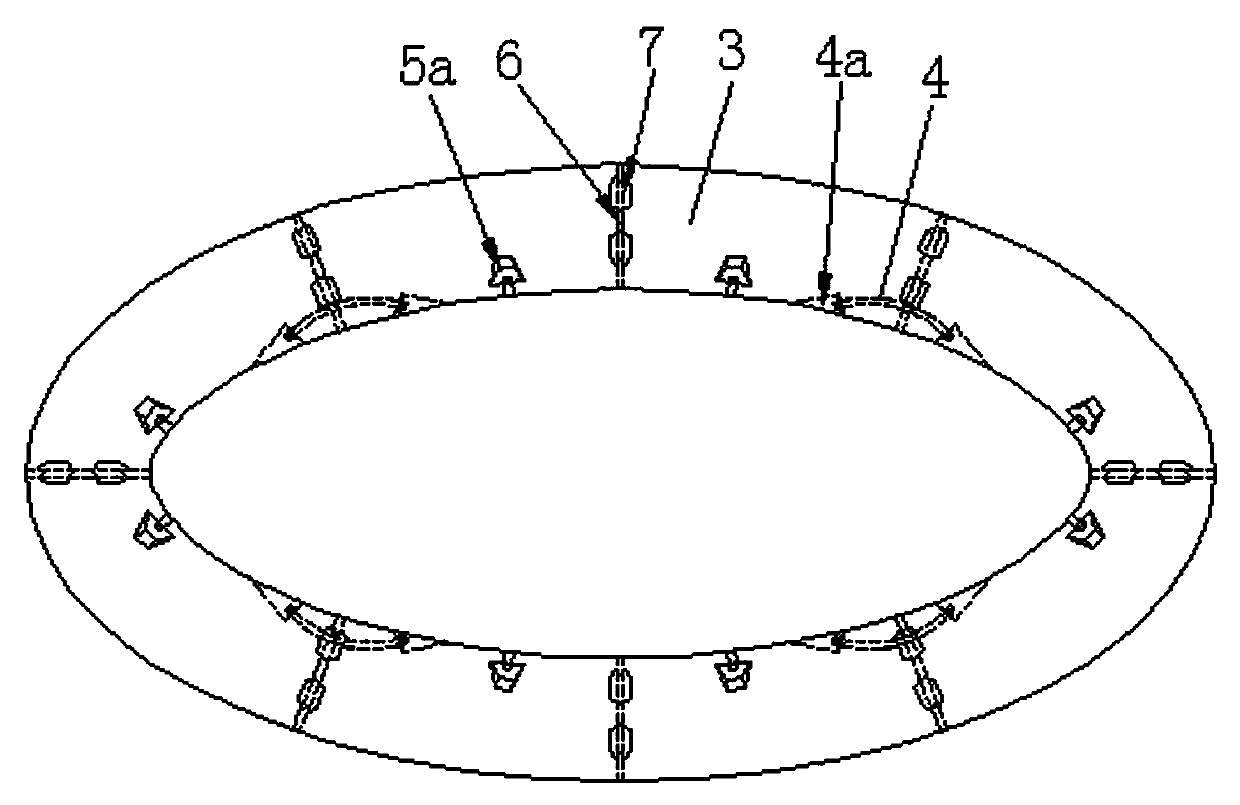

[0026] Such as Figure 1 to Figure 2 Shown is the structural representation of the present invention,

[0027] The reference signs are: bridge substructure main body 1, splicing layer 2, precast concrete segment 3, horizontal prestressed high-strength bolt 4, horizontal connecting hole 4a, vertical prestressed high-strength bolt 5, vertical connecting hole 5a, concrete Segment seam 6, elastic gasket 7.

[0028] Such as Figure 1 to Figure 2 as shown,

[0029] The precast concrete segment prestressed assembly structure of the caisson bridge substructure includes the bridge substructure main body 1, the bridge substructure main body 1 is spliced layer by layer by the splicing layer 2, and the splicing layer 2 is formed by the end-to-end connection of the precast concrete segments 3 The precast concrete segments 3 in the same splicing layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com