Inspection methods for round holes in material

A circular hole and probe technology, applied in the analysis of materials, material magnetic variables, material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as difficult probe manipulation, long inspection time, and complex manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As described above, the present invention provides a probe for use in inspection methods of substantially circular holes such as, for example, bolt holes or boreholes in turbine components.

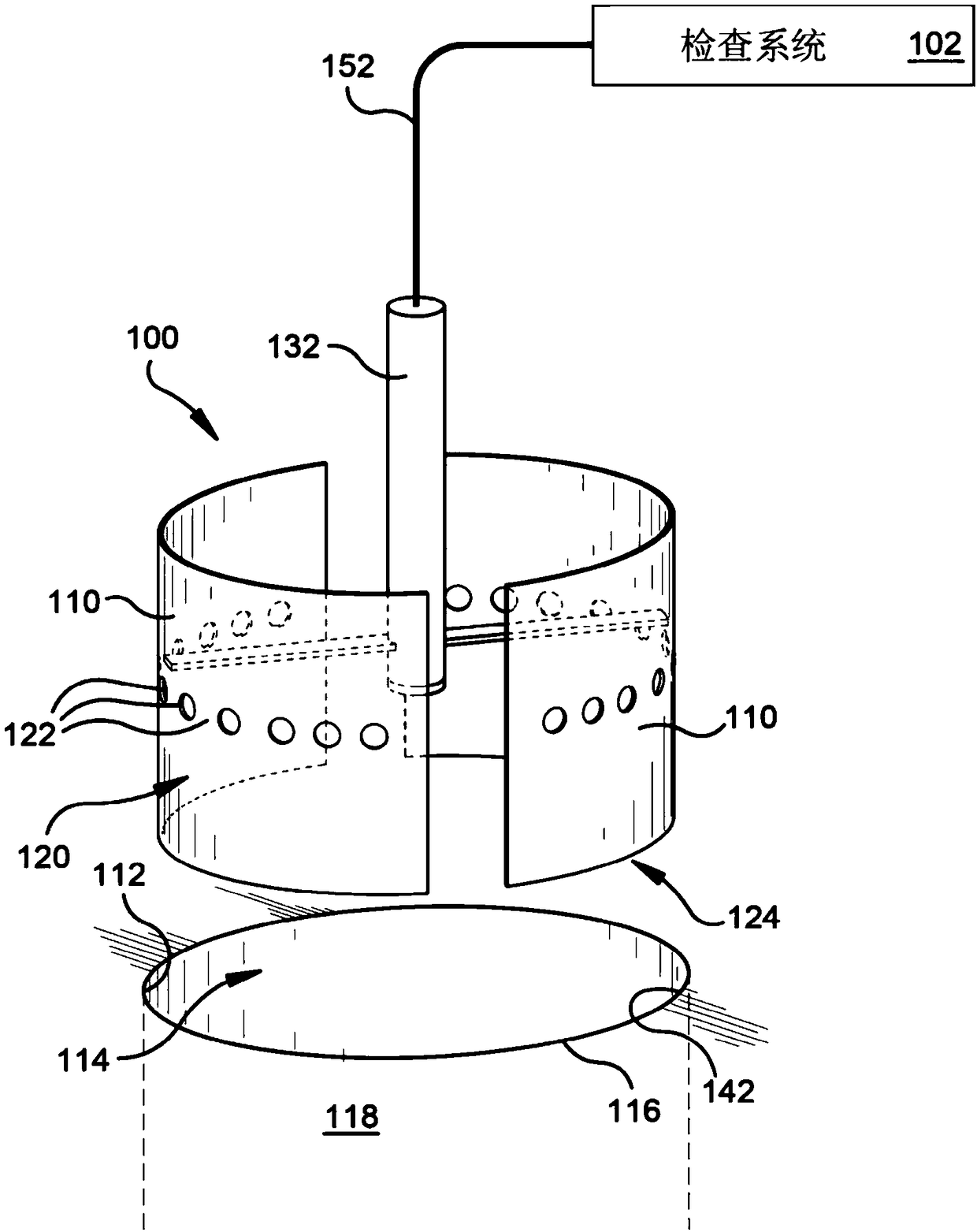

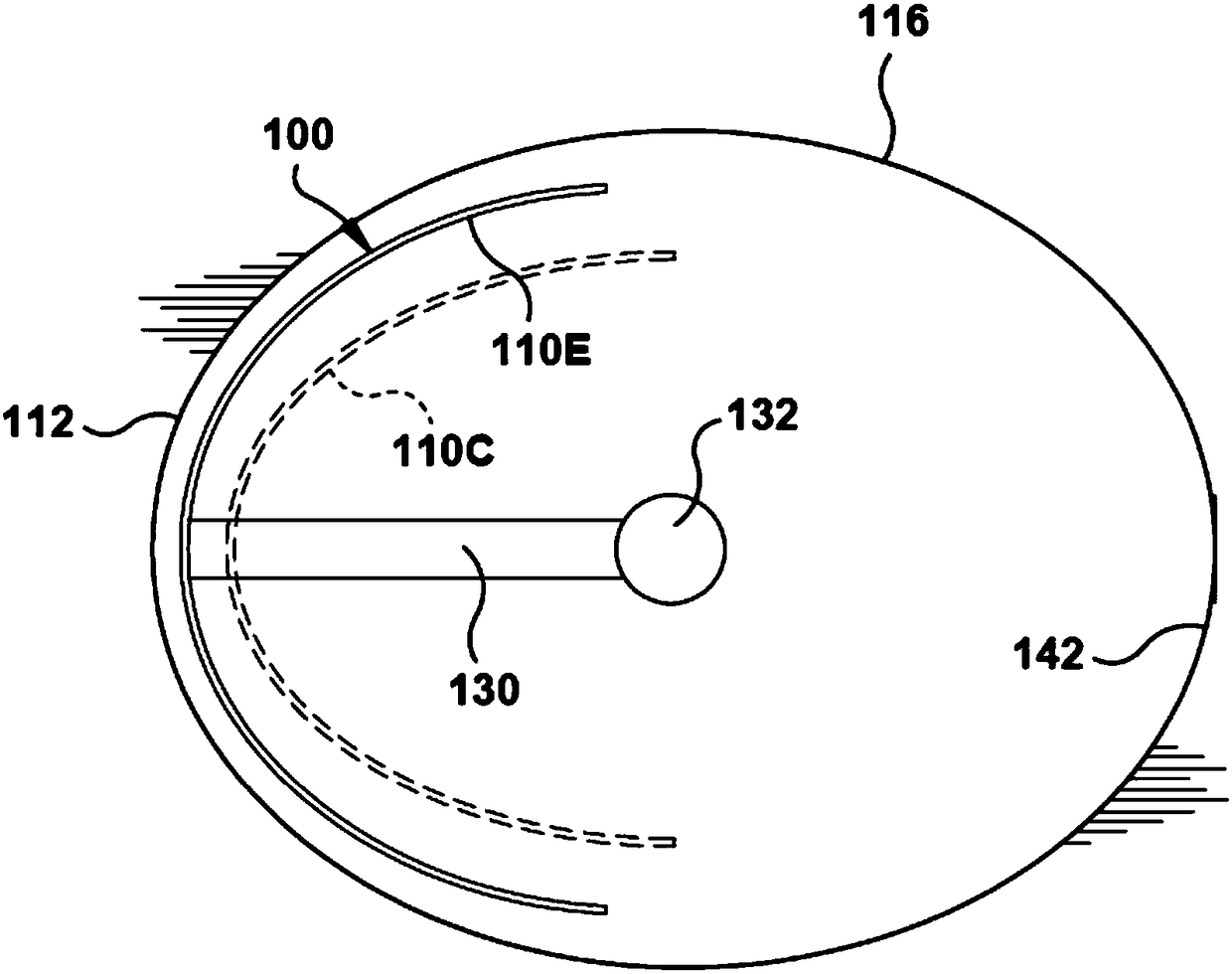

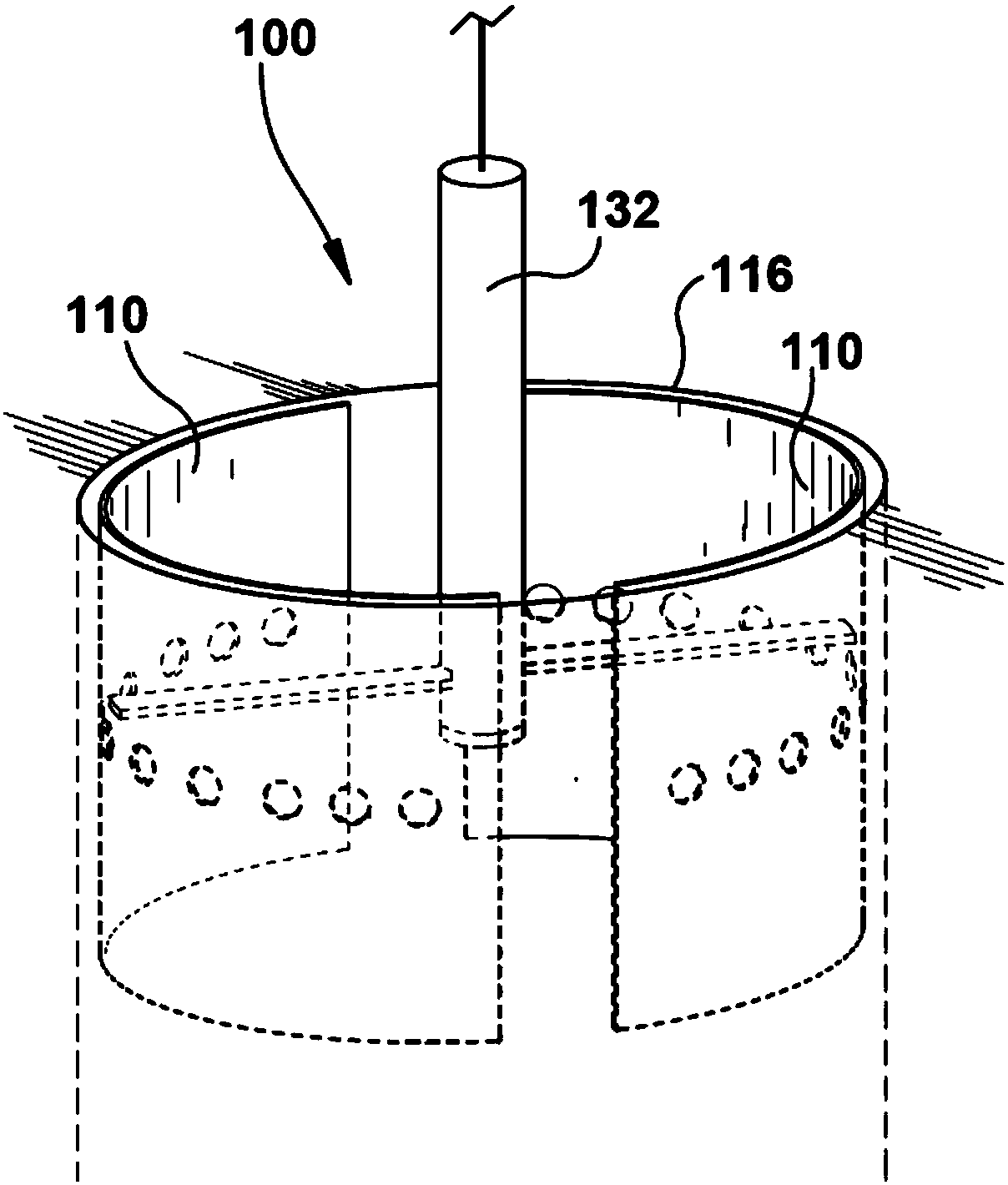

[0035] refer to Figures 1 to 3 , in one embodiment, a probe 100 of an inspection system 102 for a substantially circular hole in a material is illustrated. Inspection system 102 may include any now known or later developed eddy current or ultrasonic inspection system capable of operatively coupling with a probe according to the present invention. As can be appreciated, inspection system 102 includes a control system for passing probes such as, Figures 1 to 3 Probe 100 in or Figures 4 to 6 The probe 200 in ) transmits an eddy current or ultrasonic signal, receives a return signal and analyzes the return signal so that the structure of the material over which the signal is transmitted can be analyzed and / or imaged. Such inspection systems 102 are particularly capable of identif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com