Workpiece leveling device based on laser displacement sensor

A technology of laser displacement and leveling device, applied in instruments, simulators, control/adjustment systems, etc., can solve problems such as inability to guarantee workpiece leveling accuracy and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

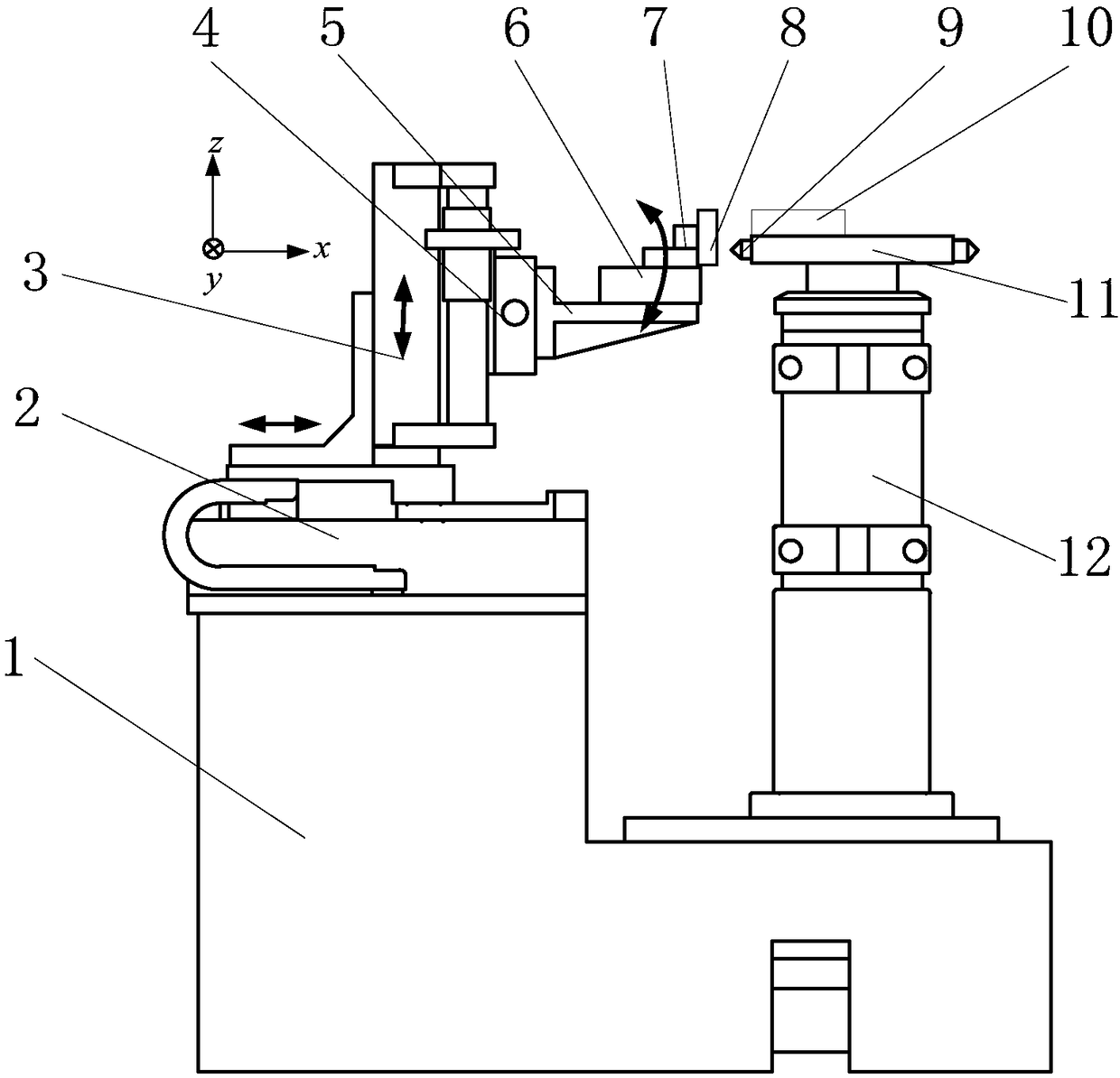

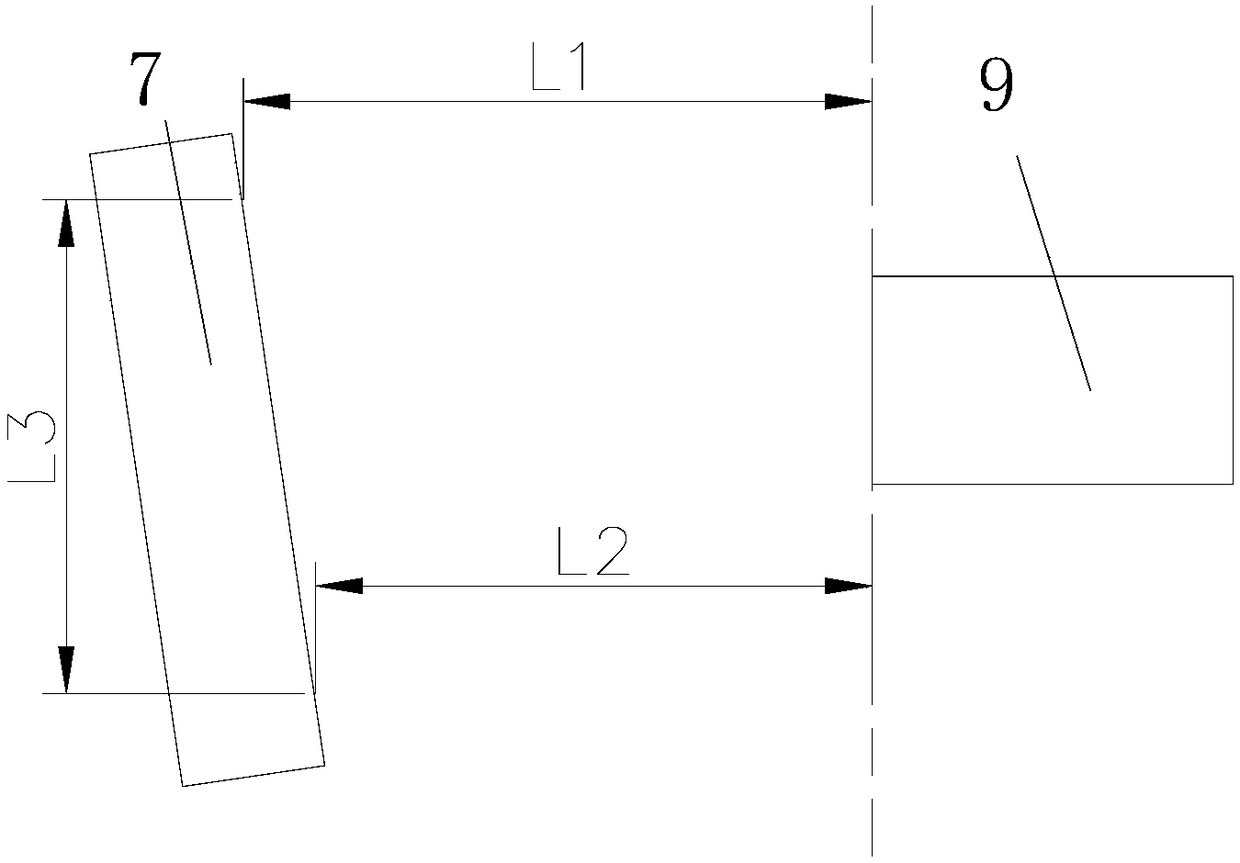

[0027] Workpiece leveling device based on laser displacement sensor, please refer to figure 1 and figure 2 , including bed 1, X-direction feed mechanism 2, Z-direction feed mechanism 3, dynamometer 4, adapter plate 5, angle fine-tuning mechanism 6, fixture 7, sample 8, tool 9, laser displacement sensor 10, Turntable 11, main shaft, motor 12 and control system.

[0028] The X-direction feed mechanism 2 is installed between the bed 1 and the Z-direction feed mechanism 3 so that the Z-direction feed mechanism 3 can feed along the X direction. Between the feeding mechanism 2 and the adapter plate 5 so that the adapter plate 5 can be fed along the Z direction, the angle fine-tuning mechanism 6 is installed between the adapter plate 5 and the clamp 7 so that the clamp 7 can rotate relative to the Y direction, The clamp 7 clamps the sample 8; the rotary disk 11 is rotatably installed on the bed 1 and the motor 12 is connected to the rotary disk 11 by transmission, the tool 9 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com