Adsorption method of warped wafer and device using the adsorption method

A wafer and warping technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as affecting productivity, reducing wafer warpage, and inability of wafer to be adsorbed, so as to reduce costs, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0036] Preferred embodiment:

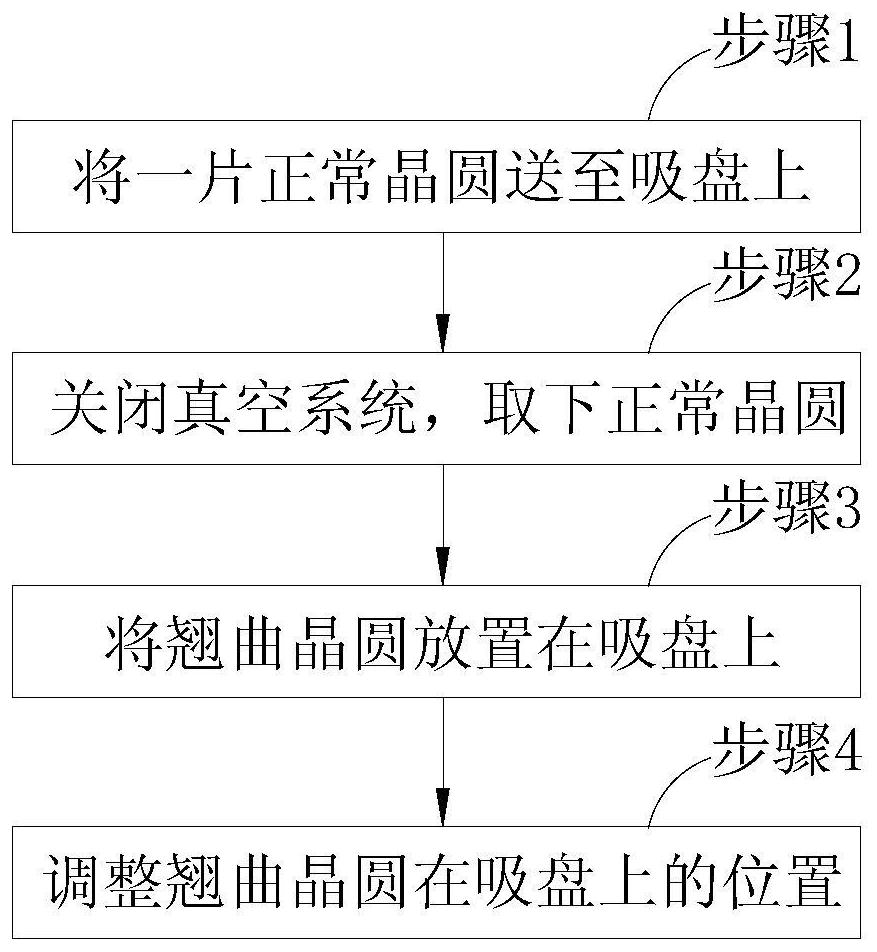

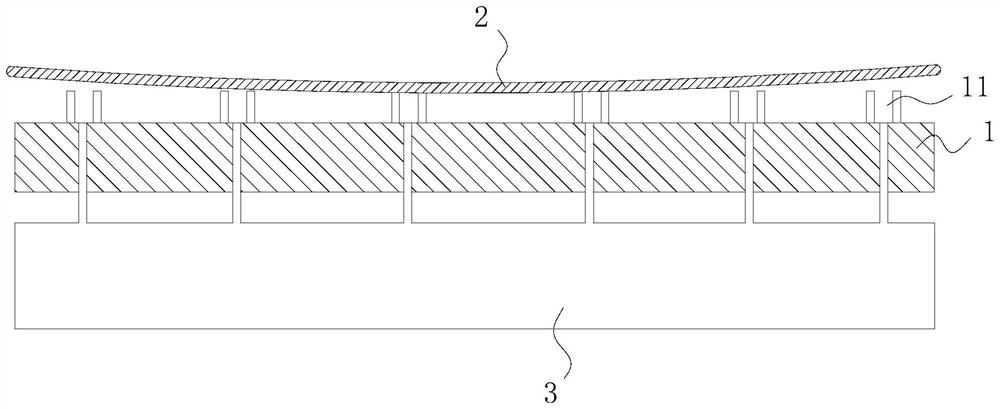

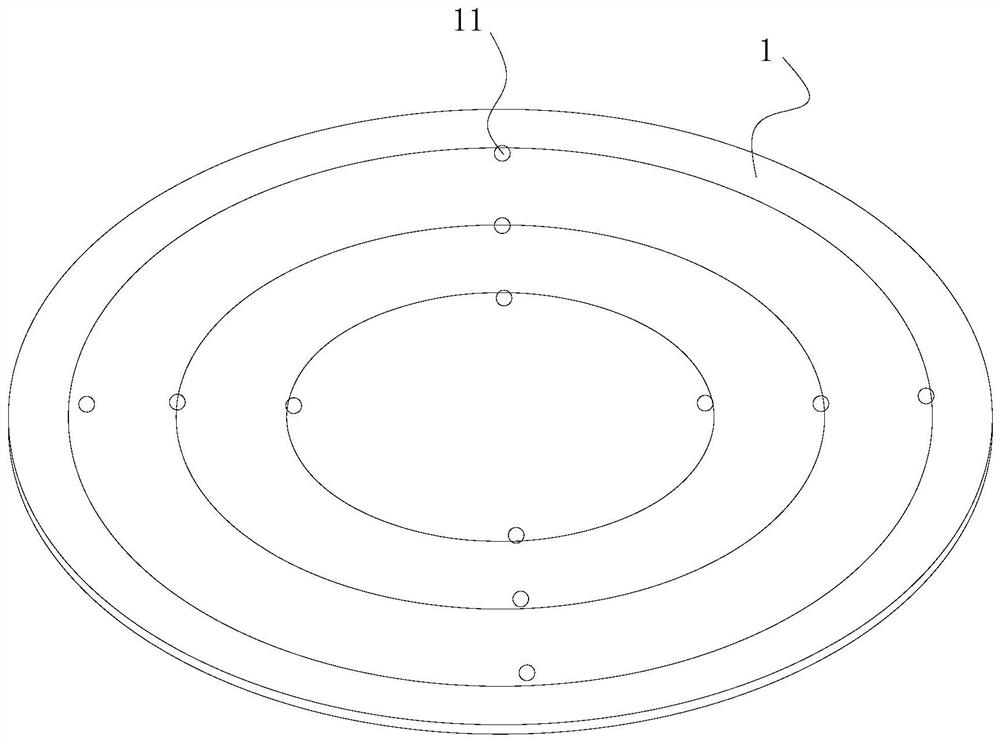

[0037] This preferred embodiment discloses an adsorption method for a warped wafer. The adsorption method is to use a normal wafer to form a normal adsorption state on the chuck 1, then use a warped wafer 2 to replace the normal wafer, and adjust the position of the warped wafer 2 on the chuck 1 horizontally and / or rotate until it is warped. The curved wafer 2 is adsorbed on the chuck 1 .

[0038] The production and processing of semiconductor wafers takes a relatively long time, especially those wafers with more complicated processing procedures. At the final stage of the entire processing (such as engraving metal wiring or pressing points), it is found that some products cannot be processed due to warping and deformation. Re-introduction of a certain amount of prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com