A kind of slow-release polycarboxylate superplasticizer and preparation method thereof

A slow-release polycarboxylic acid and superplasticizer technology, which is applied in the field of building materials, can solve problems such as difficulty in meeting engineering needs, unfavorable industrial production, and limited slump loss, and achieve good slump retention and water reduction effects, The effect of prolonged slump retention time and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of slow-release polycarboxylate superplasticizer:

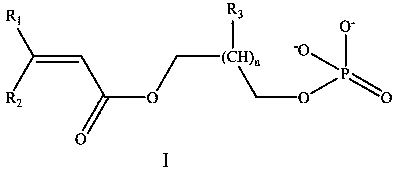

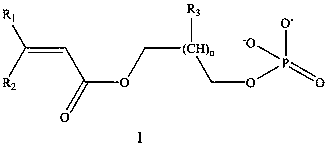

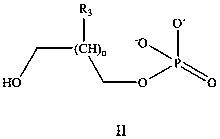

[0053] Add 14.20g of phosphorus pentoxide, 9.21g of glycerin and 0.42g of catalyst phosphotungstate-loaded activated carbon into a three-necked flask, perform nitrogen replacement three times, and start stirring. Control the reaction temperature at 60-70°C, keep it warm for 4 hours, add 9.8g of maleic anhydride after the reaction, and carry out nitrogen replacement three times, keep the reaction temperature at 70-80°C for 6 hours, and discharge the material to obtain the unsaturated ester. for DT-A. Gained unsaturated ester structural formula is shown in formula I, R 1 for -H, R 2 for -COOH, R 3 is -OH, n=1.

[0054] Add 300g of deionized water, 30g of unsaturated ester DT-A, and 360g of isopentenyl polyoxyethylene ether (relative molecular weight: 3000) into a 1000ml four-neck flask equipped with an electric stirring device and a peristaltic pump, and stir until it is completely dissolved , then add t...

Embodiment 2

[0056] Preparation of slow-release polycarboxylate superplasticizer:

[0057] Add 14.20g of phosphorus pentoxide, 7.61g of 1,3-propanediol and 0.32g of catalyst phosphotungstate-loaded activated carbon into a three-necked flask, perform nitrogen replacement three times, and start stirring. Control the reaction temperature at 55-60°C, keep it warm for 4.5 hours, add 9.80g of maleic anhydride after the reaction, and perform nitrogen replacement three times, keep the reaction temperature at 75-80°C for 6 hours, then discharge the material to obtain unsaturated ester, record It is DT-B, and the obtained unsaturated ester structural formula is shown in formula I, wherein R 1 for -H, R 2 for -COOH, R 3 It is -H, n=1.

[0058] Add 300g of deionized water, 32g of unsaturated ester DT-B, and 360g of isopentenyl polyoxyethylene ether (relative molecular weight: 3000) into a 1000ml four-neck flask equipped with an electric stirring device and a peristaltic pump, stir and heat up until...

Embodiment 3

[0060] Preparation of slow-release polycarboxylate superplasticizer:

[0061] Add 14.20g of phosphorus pentoxide, 6.21g of ethylene glycol and 0.38g of catalyst phosphotungstate-loaded activated carbon into a three-necked flask, perform nitrogen replacement three times, and start stirring. Control the reaction temperature at 55-60°C, keep it warm for 4.5 hours, add 9.80g of maleic anhydride after the reaction, and perform nitrogen replacement three times, keep the reaction temperature at 75-80°C for 6 hours, and discharge the material to obtain unsaturated ester, record It is DT-C, and the obtained unsaturated ester structural formula is shown in formula I, wherein R 1 for -H, R 2 is -COOH, n=0.

[0062] The slow-release polycarboxylate superplasticizer was prepared according to the method of Example 1, except that the unsaturated ester used was DT-C, and the solid content of the resulting product was 39.5%, which was designated as HPC-C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com