Multiplex-irradiation type inrfrared ray cooker of heat source

An infrared and cooker technology, applied in roaster/barbecue grids, kitchen utensils, home utensils, etc., can solve the problems of uncooked cooking materials, reduced food taste, and large time consumption in surrounding areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

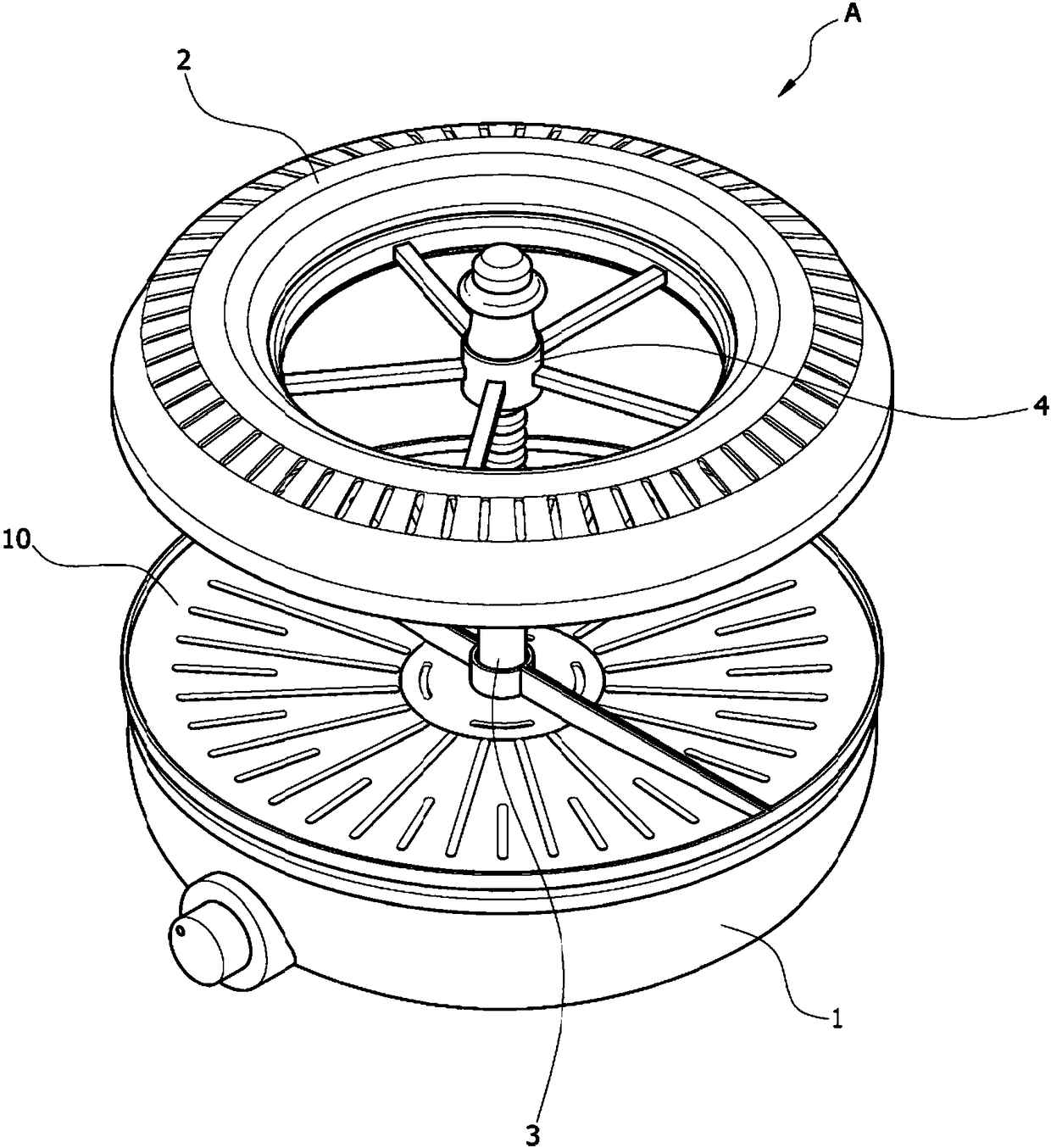

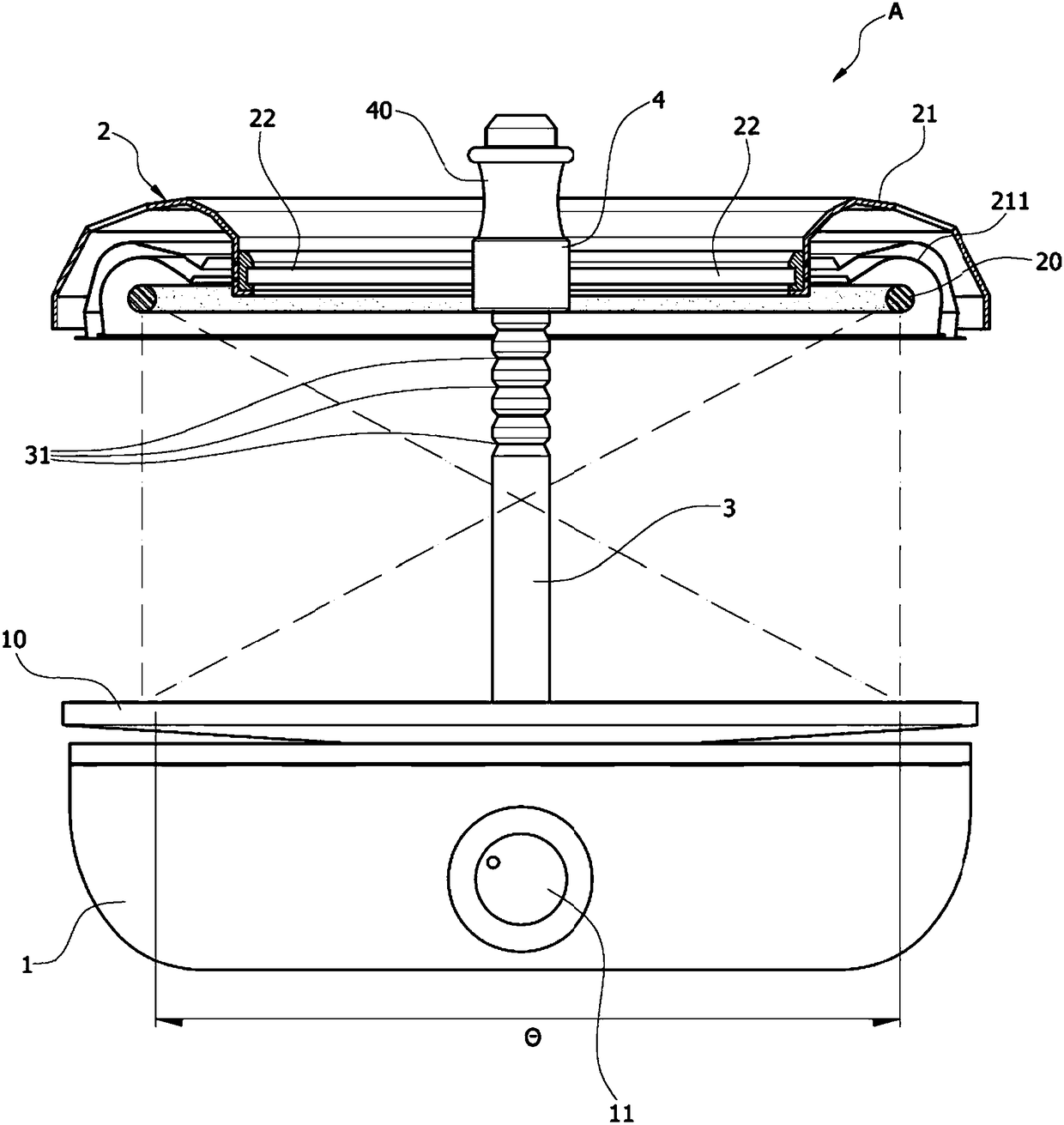

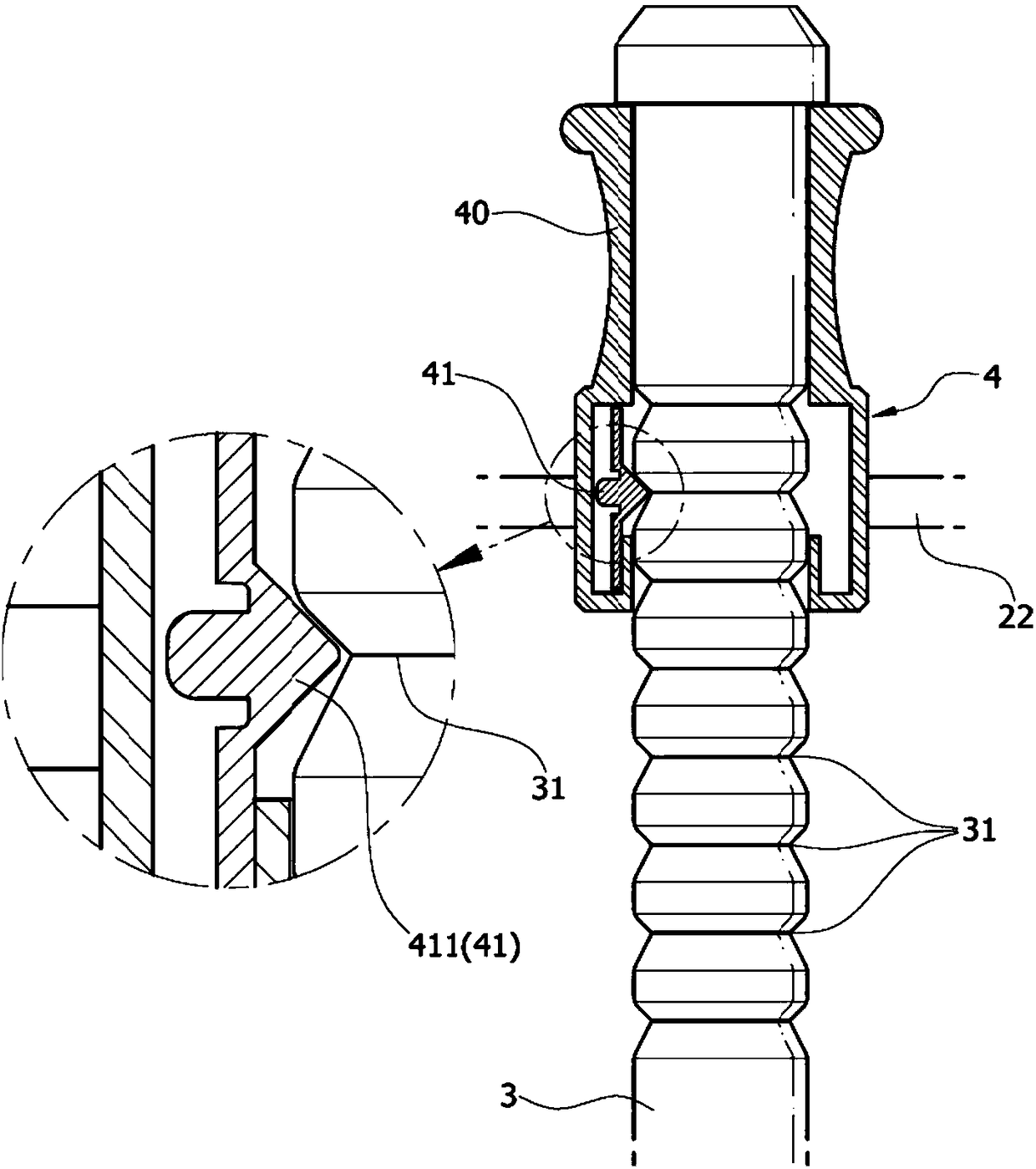

[0032] Next, preferred embodiments of the heat source multi-irradiation type infrared cooker of the present invention will be described with reference to the accompanying drawings.

[0033] In the attached picture, figure 1 It is a perspective view illustrating the overall structure of the heat source multi-irradiation infrared cooker according to the present invention, figure 2 It is a partial cross-sectional view illustrating the structural relationship of the heating head in the heat source multi-irradiation infrared cooker according to the present invention, image 3 It is a partially enlarged cross-sectional view illustrating the structural relationship of the adjustment device in the heat source multiple irradiation infrared cooker according to the present invention, Figure 4 It is an explanatory view showing a state in which a heating head is lowered in a heat source multi-irradiation type infrared cooker according to the present invention.

[0034] Next, an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com