Non-destructive testing equipment for round rod and round pipe metal materials

A metal material, non-destructive testing technology, applied in the direction of transportation and packaging, conveyor objects, sorting, etc., can solve the problems of rework, transfer of damaged materials, time-consuming and laborious, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

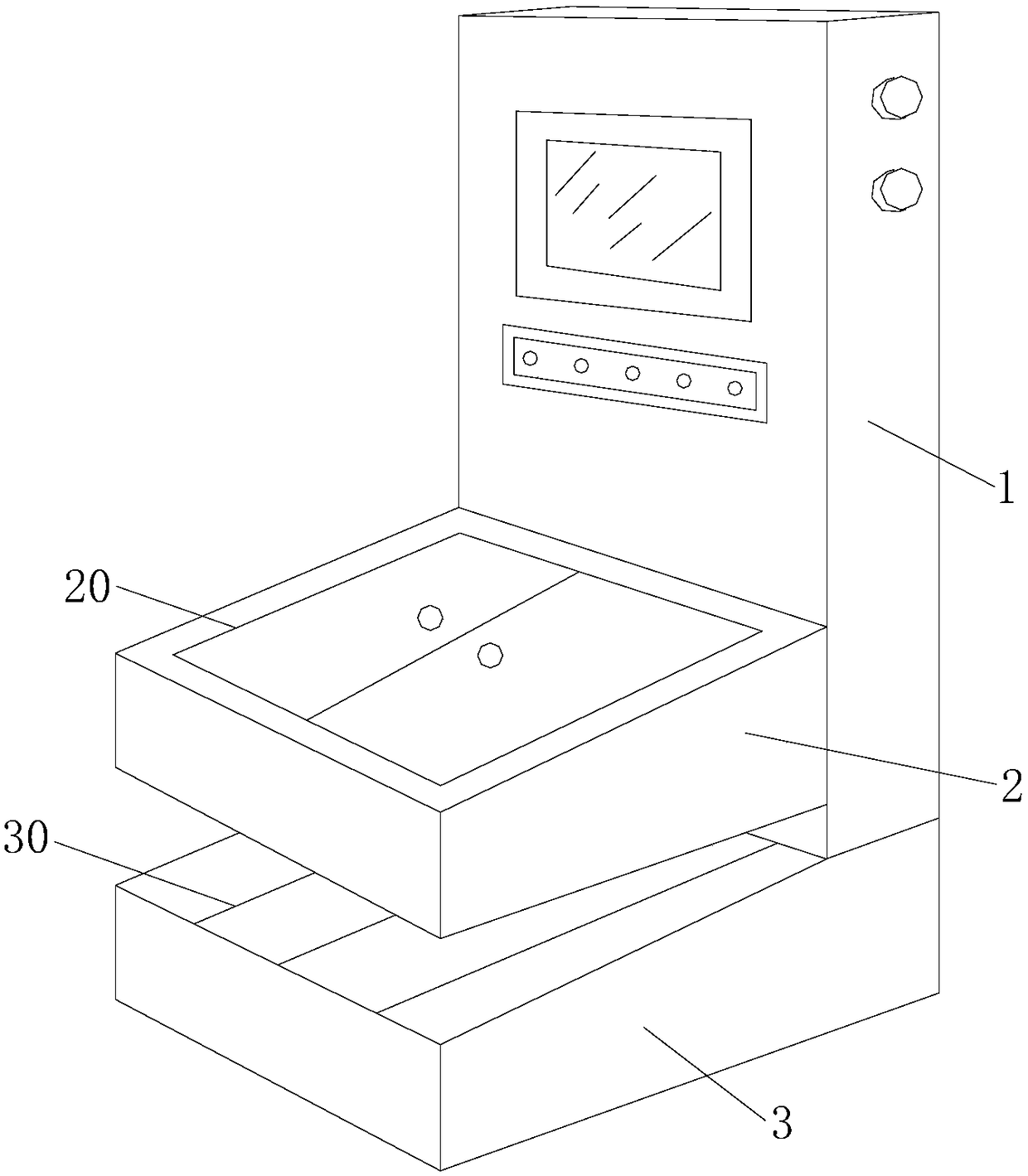

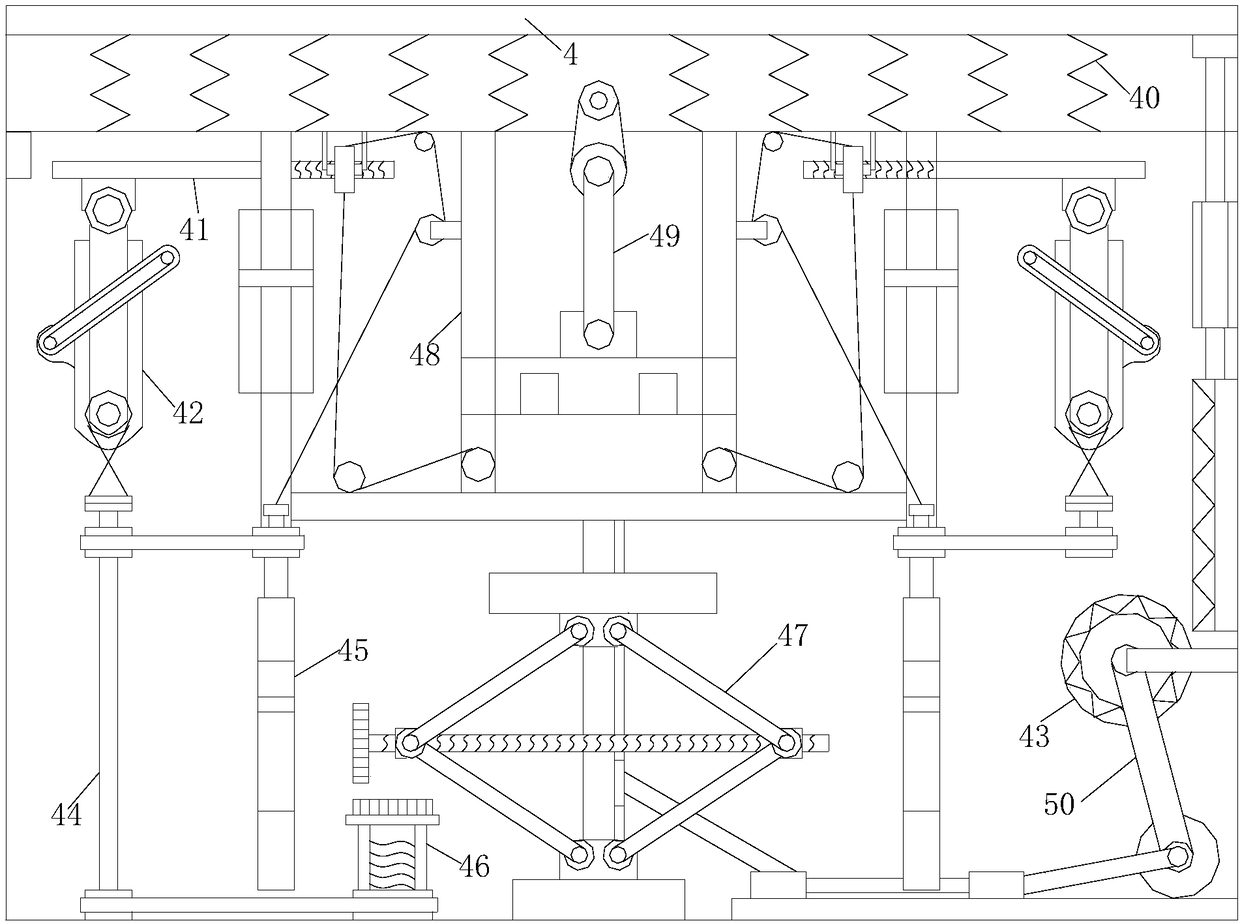

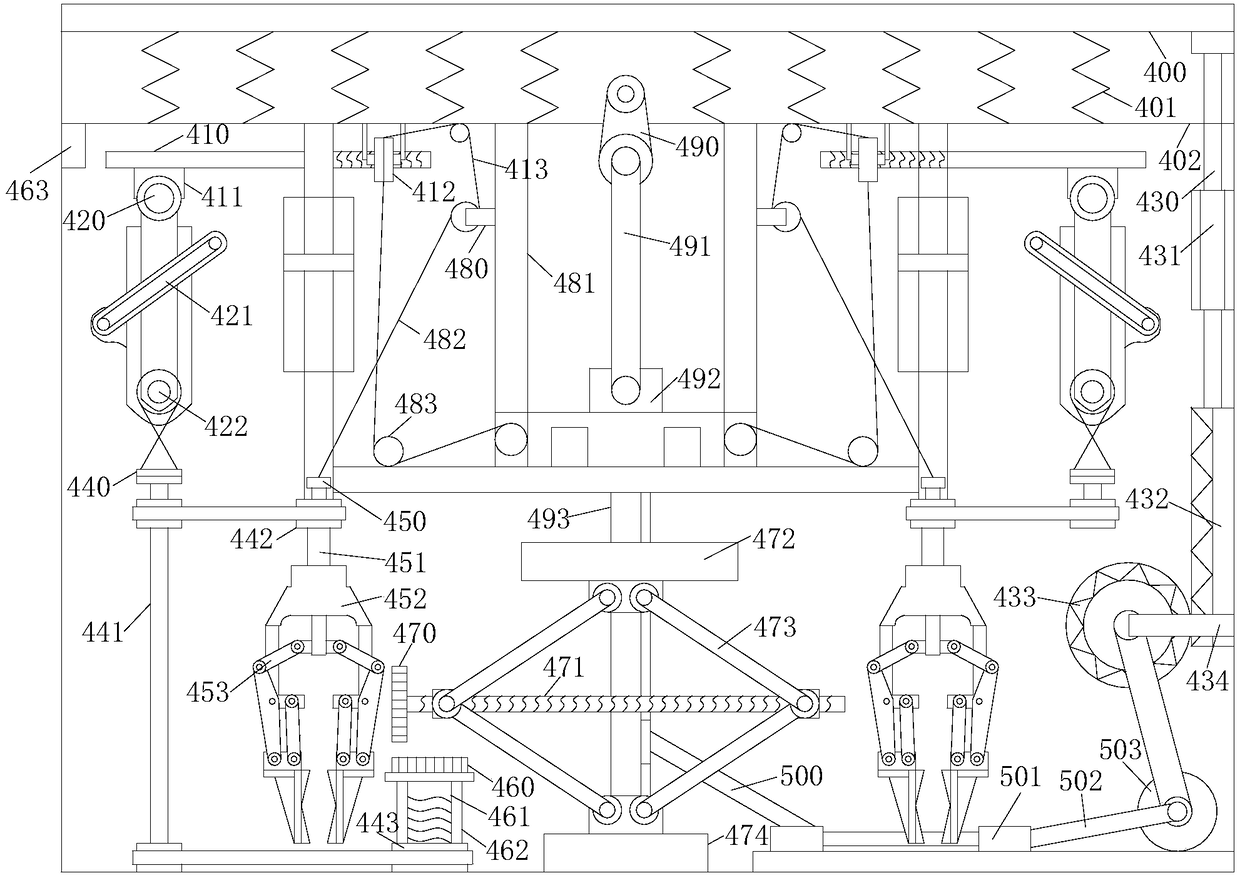

[0026] see Figure 1-Figure 3, the present invention provides a round bar and round tube metal material nondestructive testing equipment: its structure includes a control machine 1, a material transfer machine 2, a material conveyor 3, and a transfer mechanism 4, and the control machine 1 is connected to the material transfer machine 2, The material conveyor 3 is vertically connected, the material transfer machine 2 and the material conveyor 3 are parallel to each other, the transfer mechanism 4 is installed inside the material transfer machine 2, the material transfer machine 2 is located above the material conveyor 3, and the material The transfer machine 2 is equipped with a maintenance bin door 20 through a hinge, the material conveyor 3 is provided with a delivery seat 30, and the transfer mechanism 4 is composed of a spring frame 40, a threaded push rod 41, a swing rotator 42, an engaging assembly 43, a rotating Structure 44, clamping manipulator 45, meshing wheel shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com