Flange drilling mechanism applicable to automobiles

A technology for drilling mechanism and flanges, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc. It can solve the problems of difficult drilling, many processes, and reduced drilling efficiency, etc., and achieve Improve production efficiency, reduce work pressure, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

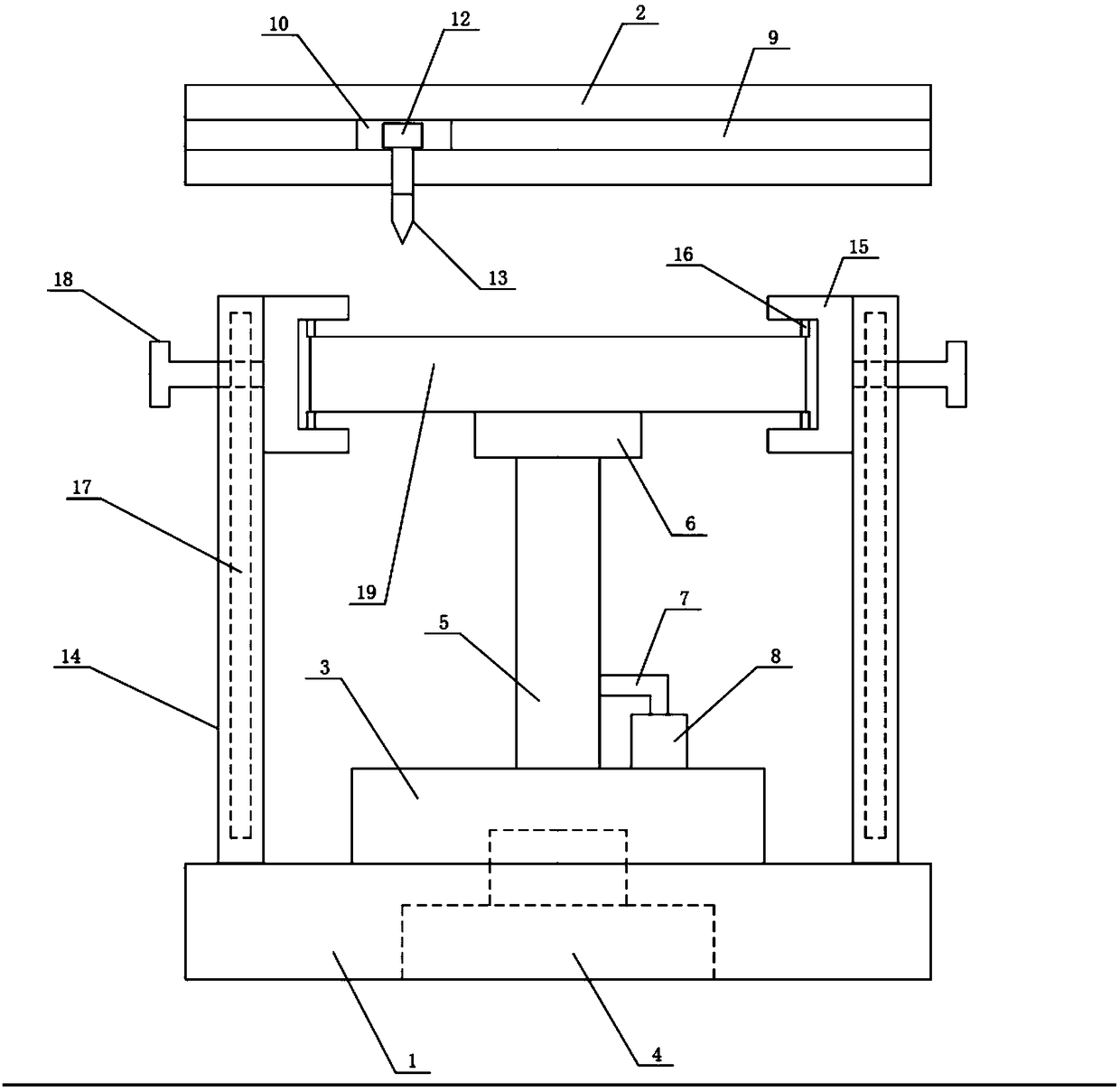

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

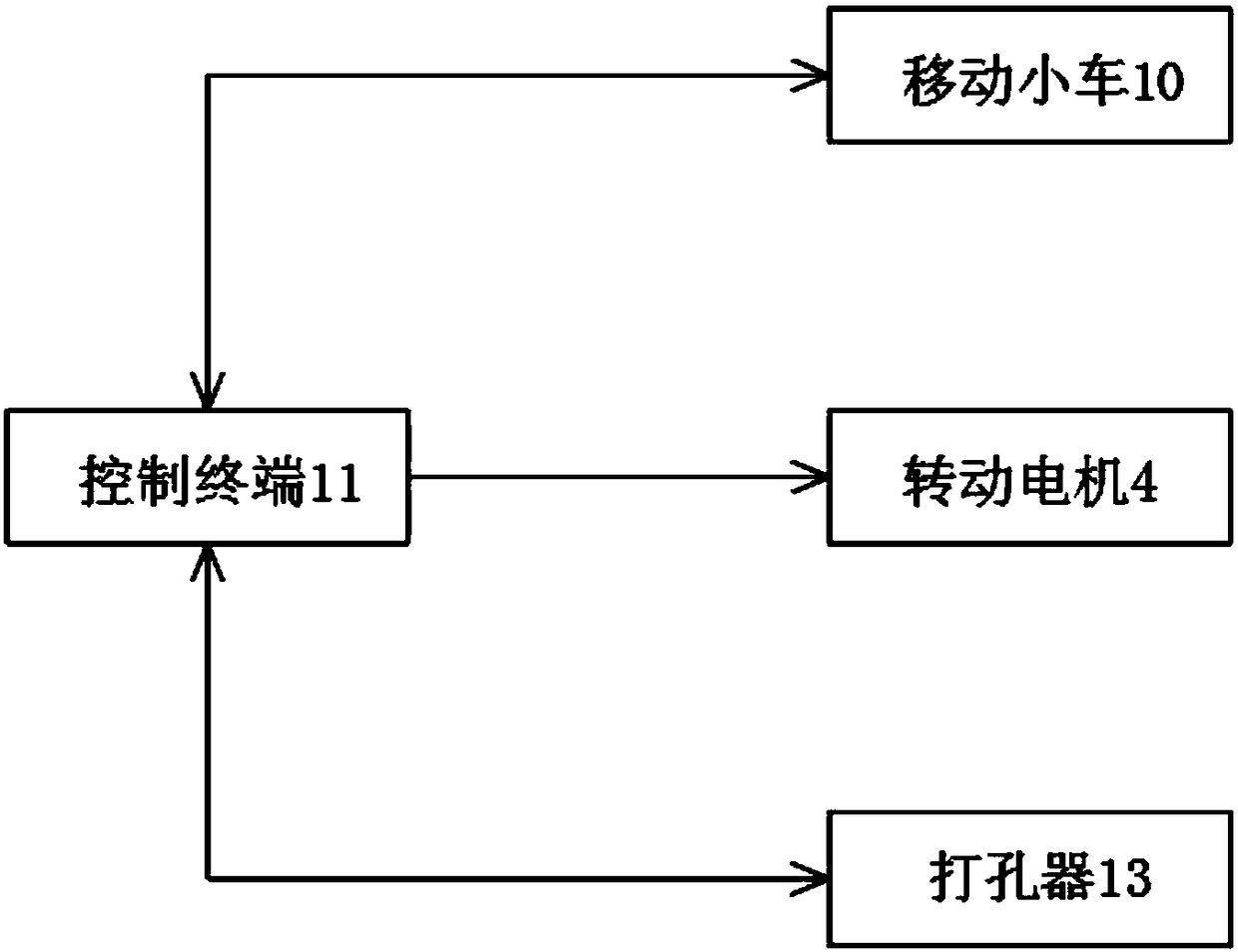

[0024] The invention provides a flange drilling mechanism suitable for automobiles. Its working principle is to realize the fixation of the workpiece to be processed through the air pump, the air pipe, the hollow column and the suction cup, and realize the hole punching by using the mobile trolley, the telescopic cylinder and the control terminal. Move to achieve the purpose of optimizing the flange drilling process, improving the drilling efficiency, reducing equipment damage and reducing the working pressure of the staff.

[0025] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

[0026] Such as figure 1 and figure 2 As shown, a flange drilling mechanism suitable for automobiles includes a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com