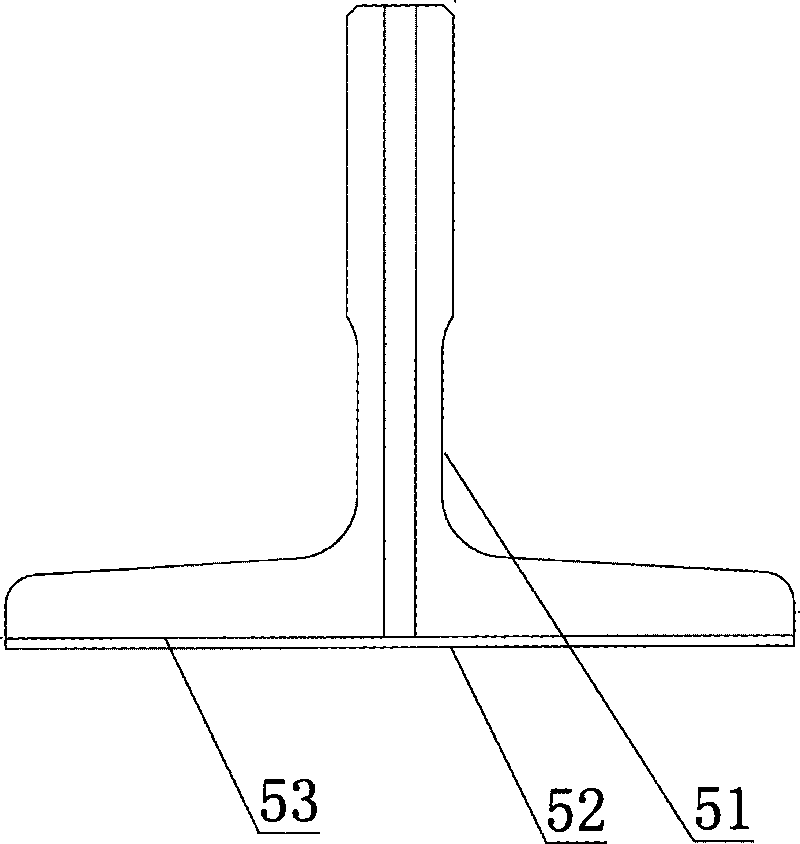

Boring-used elevator T-type lead rail automatic clamping device of NC drilling machine

A CNC drilling machine and automatic clamping technology, used in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of deformation of T-shaped guide rails, straightness of finished products, and distortions that do not meet the requirements. Achieve good support, realize automatic operation and reduce deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

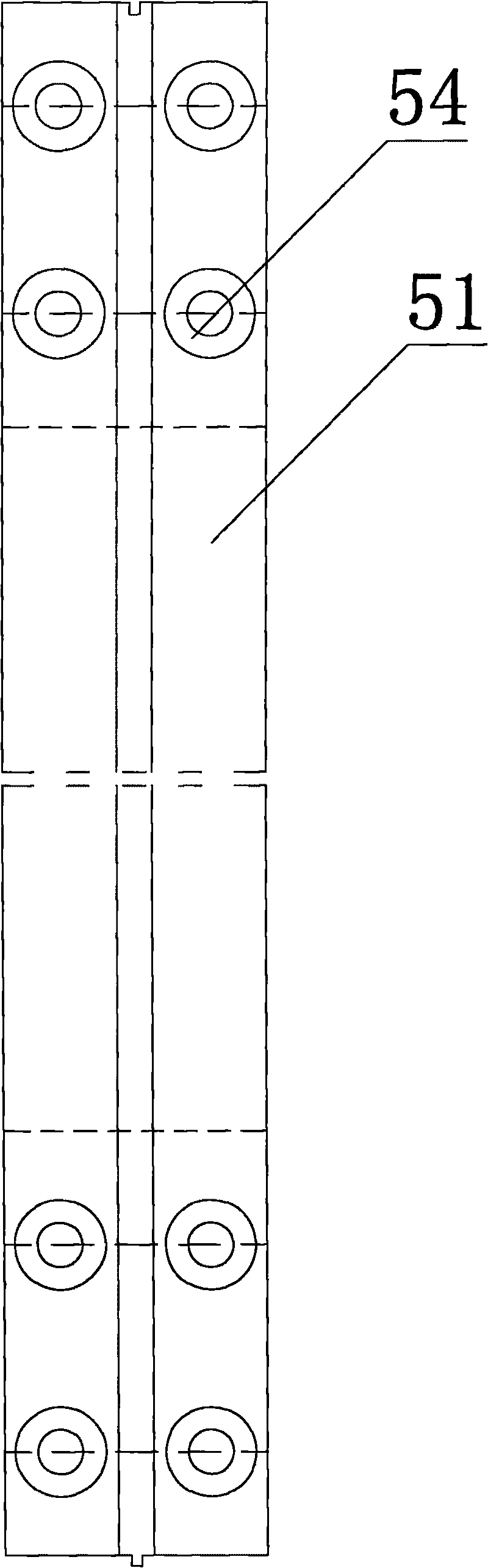

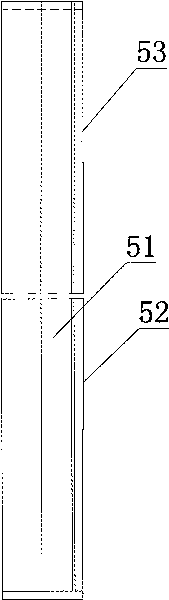

[0035] Example Figure 4-6 As shown, the automatic clamping device for the elevator T-shaped guide rail used for the drilling of the CNC drilling machine includes a positioning stopper 2 arranged on the CNC drilling machine workbench 1 to horizontally position the end of the T-shaped guide rail, and the outer side of the positioning stopper 2 is symmetrical Set the left and right horizontal clamps 3, and the left and right special-shaped rotating shafts 4 are arranged symmetrically between the left and right hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com