Full-automatic sealing machine with error contact protection device

A protection device and sealing machine technology, applied in the directions of automatic packaging control, packaging protection, packaging sealing/fastening, etc., can solve the problems of difficult installation of sealing film, limited one-way induction, damage, etc., to improve trigger speed and trigger probability, improved safety performance, and ease-of-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated in conjunction with specific embodiments.

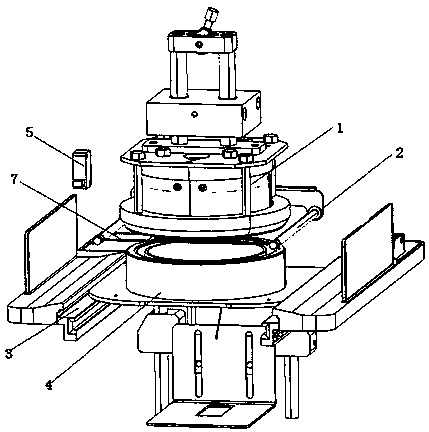

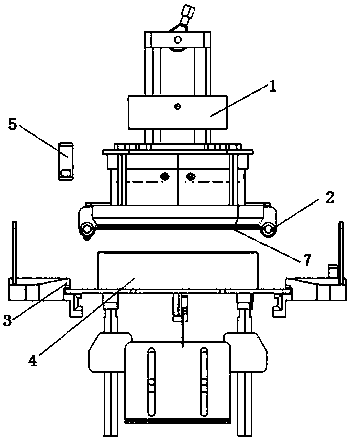

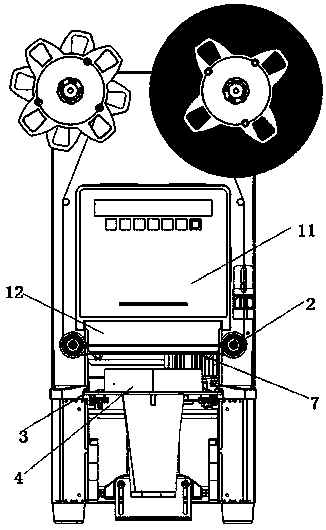

[0022] like figure 1 and figure 2 A fully automatic sealing machine with an accidental touch protection device, including a film pressing mechanism 1, a film holding rod 2, a lower mold 4 that can move back and forth along a guide rail 3, and a micro switch 5, the micro switch 5 is electrically Connect the main board 6 of the sealing machine, the front end of the film holding rod 2 is in contact with an action line 7, the film holding rod 2 and the action line 7 are both thin rods made of metal, and both ends of the action line 7 are even when subjected to external force. It can be separated from the supporting membrane rod 2, and the supporting membrane rod 2, the action line 7, the micro switch 5 and the main board 6 are connected in series to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com