A logistics delivery device

A transmission device and logistics technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of damage to the interests of the company and customers, failure to obtain buffers, hard texture of the conveying device, etc., to reduce the probability of damage to goods, Avoid falling damage to goods and reduce economic disputes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

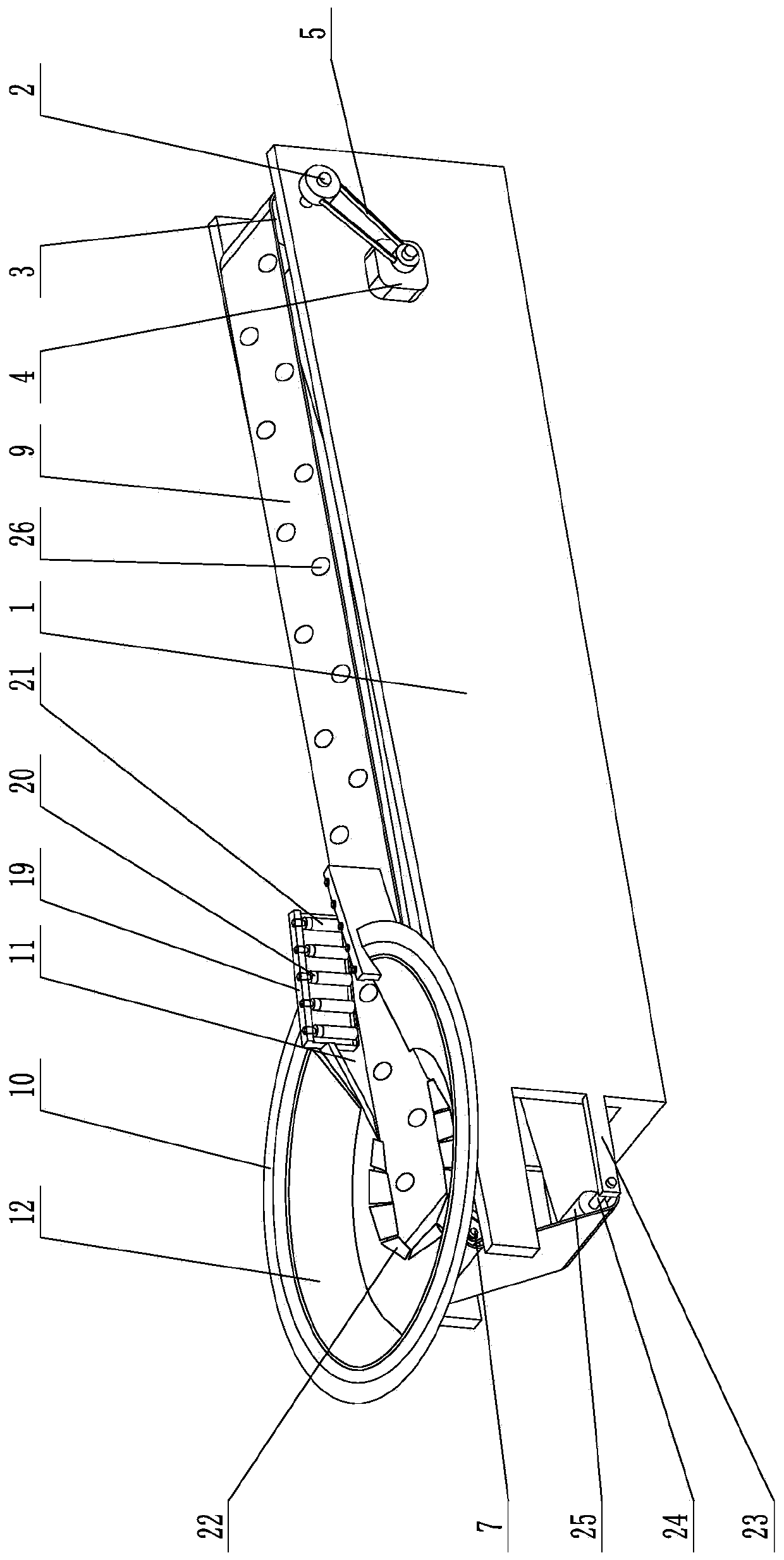

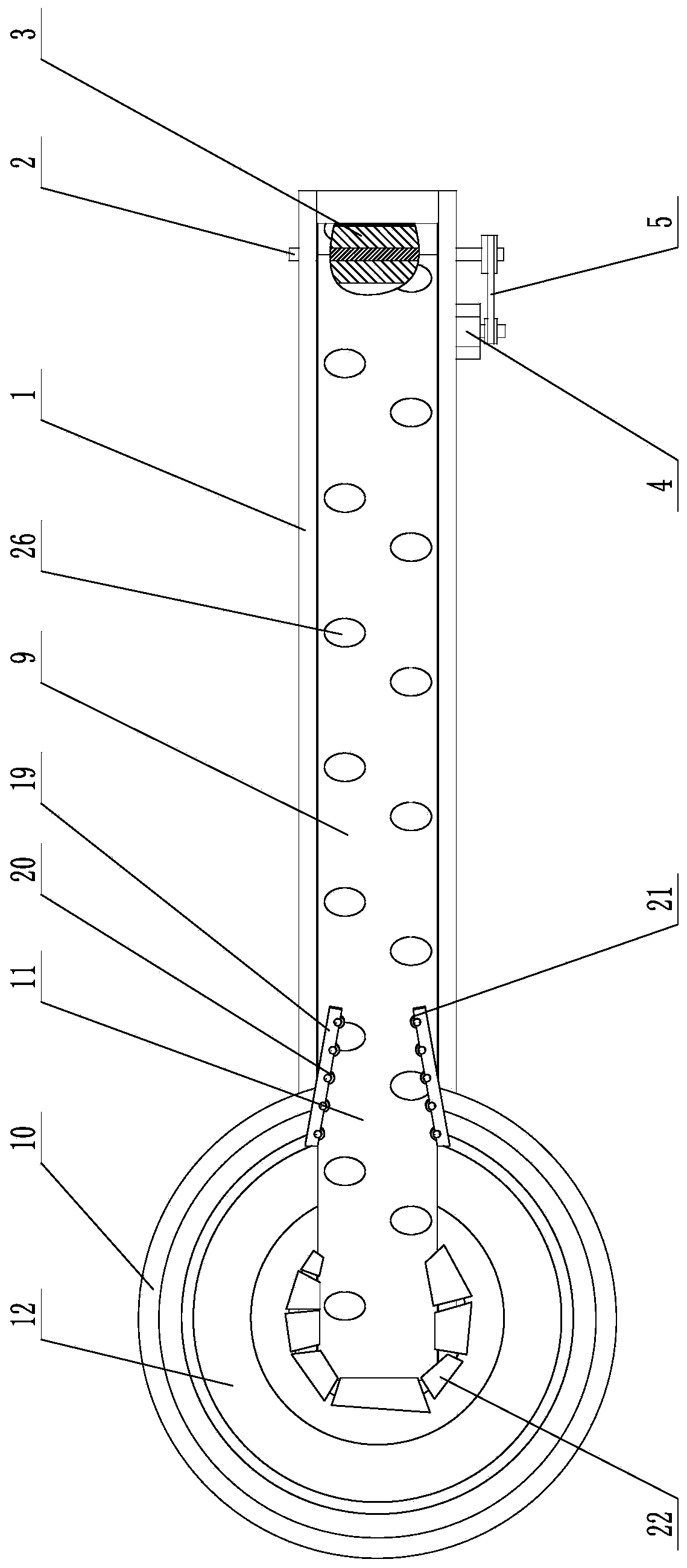

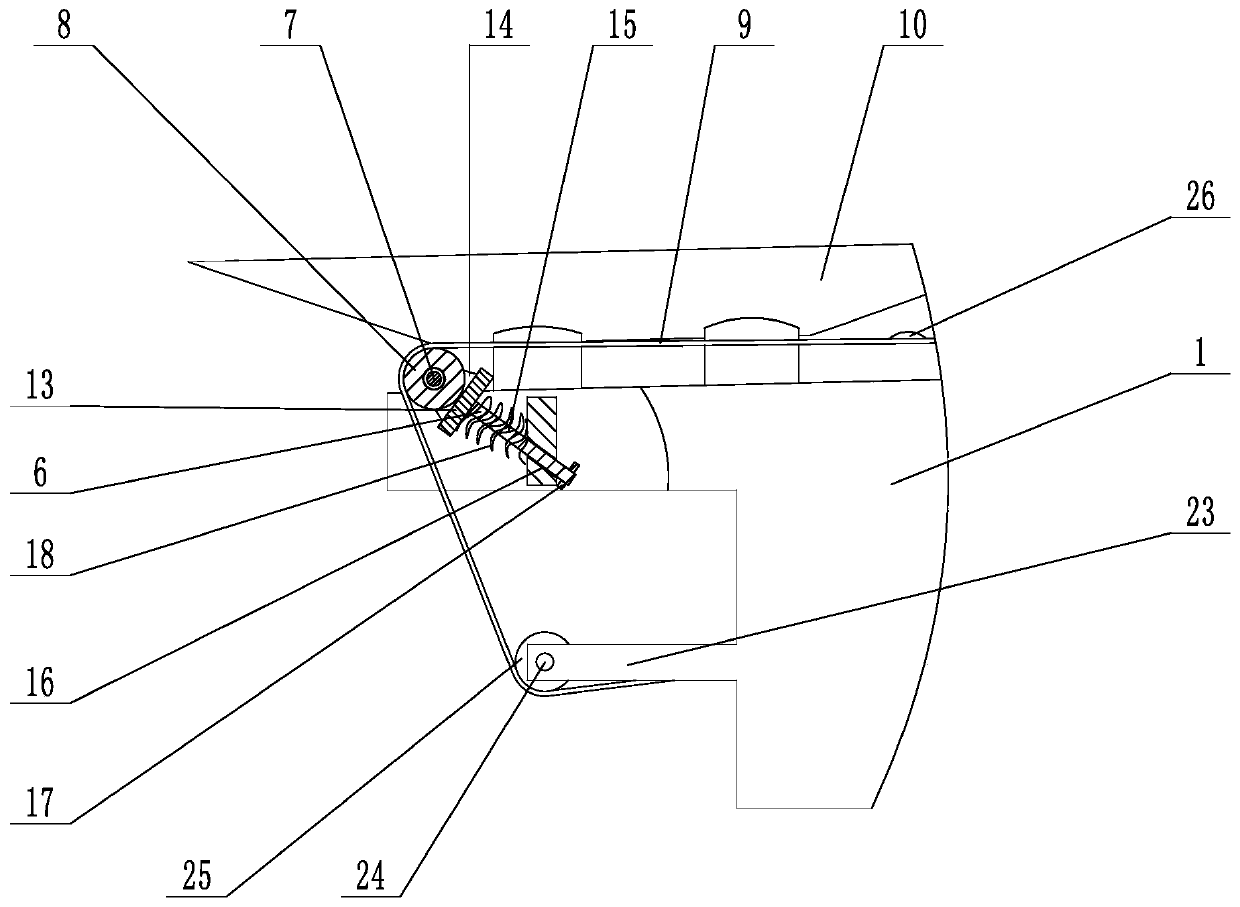

[0040] A material transport device, comprising a bracket 1, the bracket is formed by welding metal plates, the bracket in this embodiment is fixed on the ground by expansion bolts, a first rotating shaft 2 is arranged at one end of the bracket 1, and the first rotating shaft 2 is connected with the bearing of the support 1, and the first roller 3 is arranged on the first rotating shaft 2, and the first roller and the first rotating shaft can be interference fit or can be connected with a key. This embodiment adopts a key connection, and the first roller 3 A roller can be made of metal or plastic. In this embodiment, plastic is used. The motor 4 is arranged at one end of the bracket 1 near the first rotating shaft 2. The motor is a 220V AC motor, and the motor is fixed on the on the frame. A transmission device 5 is provided between the motor 4 and the first rotating shaft 2. The transmission device can be belt transmission, chain transmission or gear transmission. This embodim...

Embodiment 2

[0042] A logistics conveying device, comprising a bracket 1, the bracket is formed by welding metal plates, a wheel set is arranged at the bottom of the bracket in this embodiment, a braking device is arranged on the wheel set, a first rotating shaft 2 is set at one end of the bracket 1, The first rotating shaft 2 is bearing-connected to the bracket 1, and the first rotating shaft 2 is provided with a first roller 3, and the first roller and the first rotating shaft can be either interference fit or keyed. Fittingly, the first roller can be made of metal or plastic. In this embodiment, metal is used. A motor 4 is arranged at the end of the bracket 1 close to the first rotating shaft 2. The motor is a 220V AC motor. The motor is fixed on the frame by bolts. A transmission device 5 is provided between the motor 4 and the first rotating shaft 2. The transmission device can be a belt transmission, a chain transmission or a gear transmission. This embodiment adopts a chain transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com