Seat cloth assembling device and assembling method thereof

A technology for assembling device and seat cloth, which is applied in the production and application of household appliances and furniture covers, can solve the problems of product scrapping or secondary processing, low labor efficiency, time-consuming and labor-intensive, etc., to achieve convenient operation and avoid pulling deviation. Cloth, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

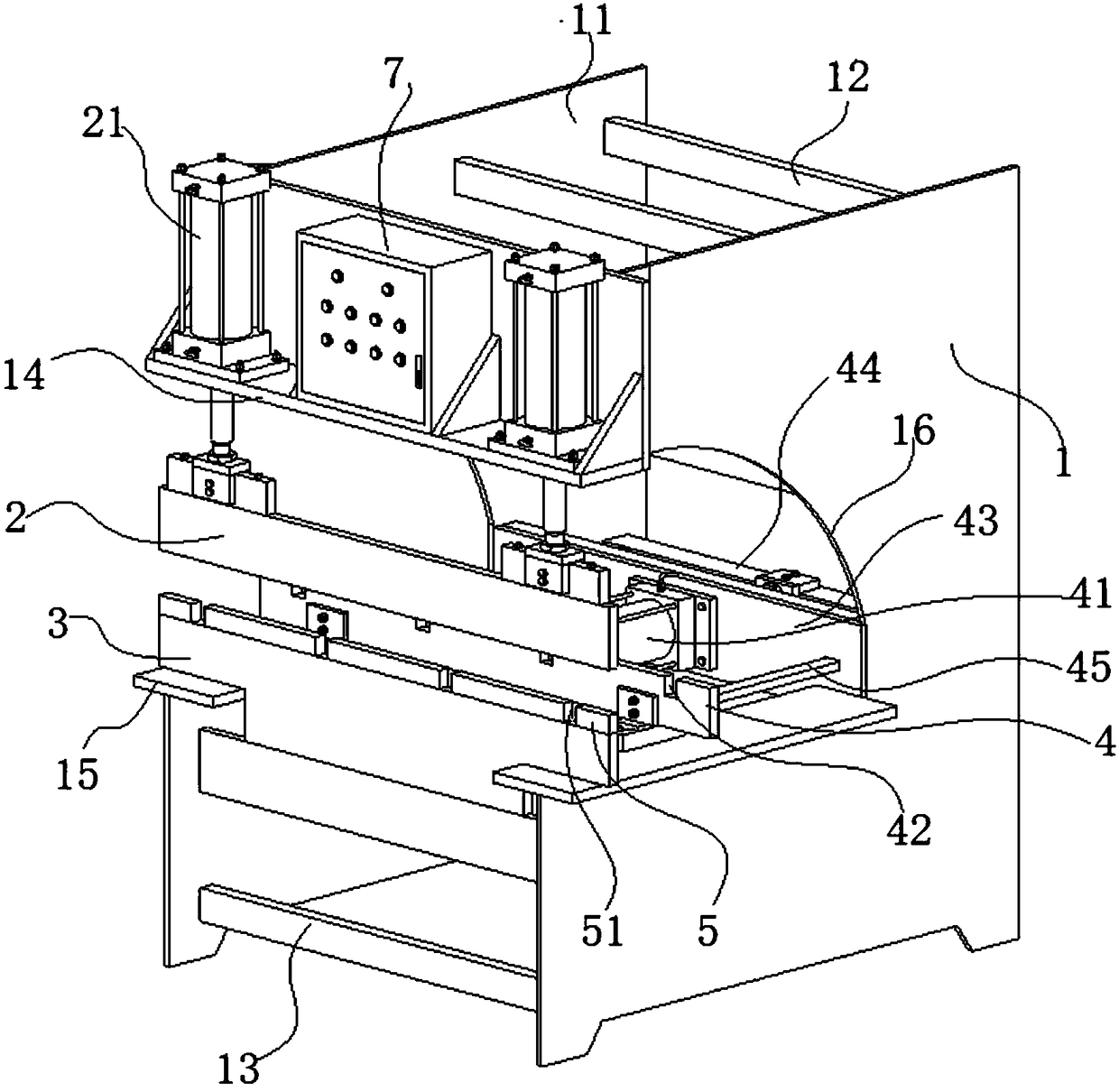

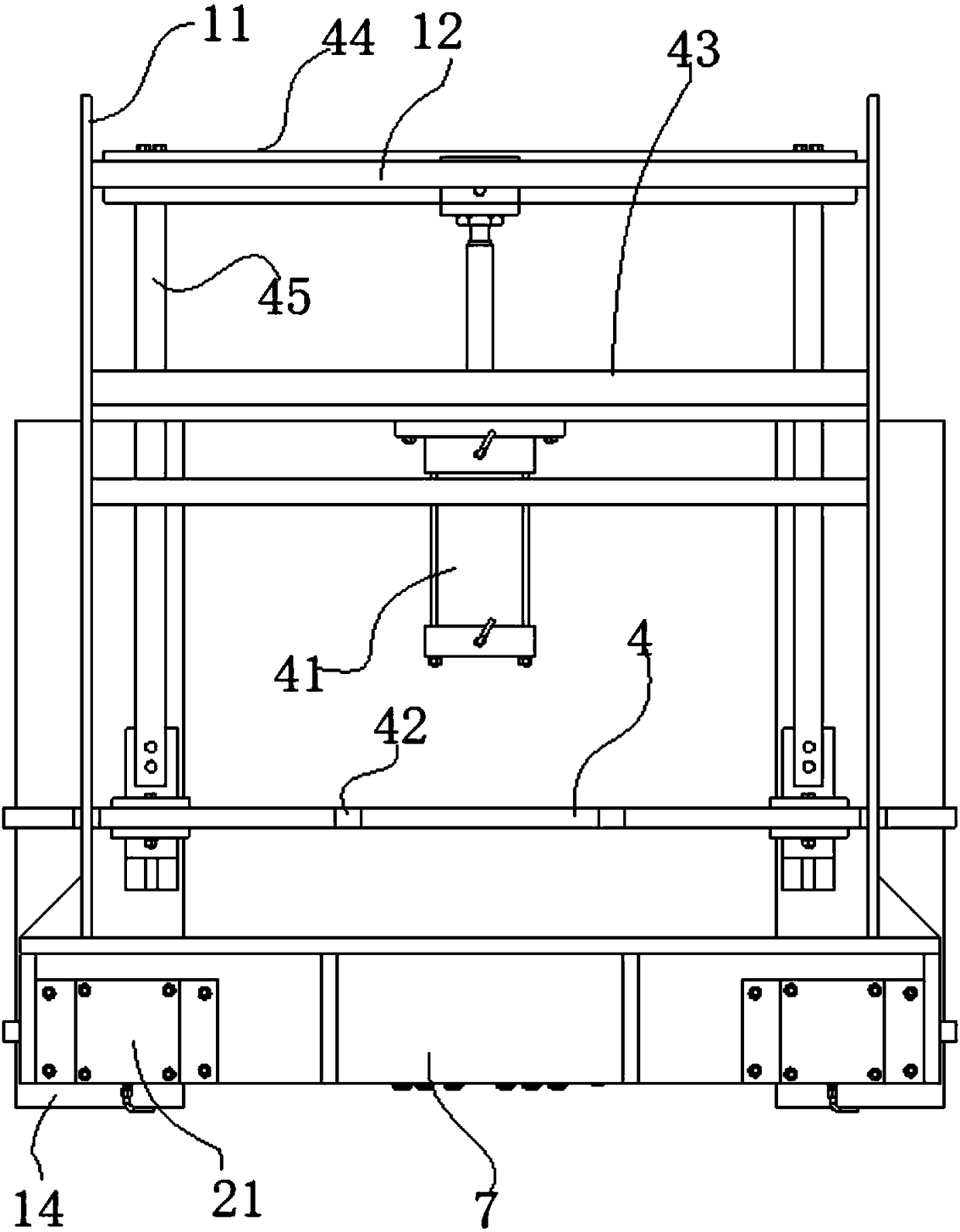

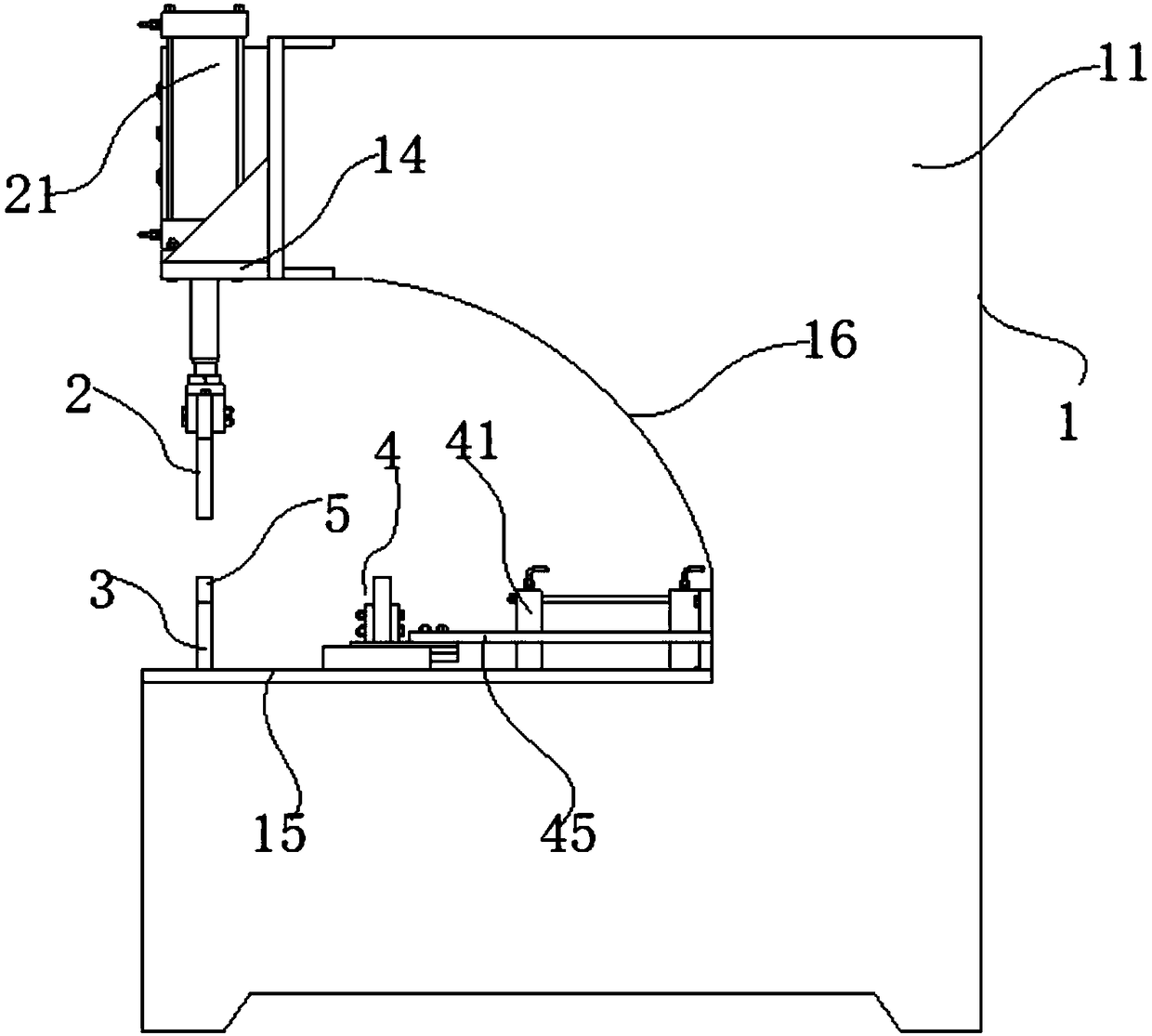

[0050] A seat cloth assembling device in this embodiment, a seat cloth assembling device, includes a main frame 1, an upper mold 2, a lower mold 3 and a tie rod mold 4; wherein: the main frame 1 is composed of two left and right structures. The frame plate 11 is formed by connecting the upper frame connecting rod 12 and the lower frame connecting rod 13; an upper platform 14 is arranged on the front upper part of the main frame 1, and a middle groove-shaped platform 15 is arranged in the middle; Air cylinder 21, the telescopic rod of the inverted air cylinder 21 is detachably connected to the upper die 2 after passing downward through the upper platform 14; The tie rod mould 4 and the lower mould 3 are arranged in the horizontal direction, and are also buckled on the middle groove-shaped platform 15 in a T-shape, and pass the telescopic rod of the horizontal cylinder 41 fixed on the middle groove-shaped platform 15. Drive the next horizontal movement.

[0051] A seat cloth as...

Embodiment 2

[0060] The basic structure of a seat cloth assembling device of this embodiment is the same as that of Embodiment 1, and the differences and improvements are as follows: figure 1 , 2 , 3, the horizontal cylinder 41 is set away from the tie rod mold 4, which improves the horizontal movement stroke of the tie rod mold in a limited operating space; the distance between the flat cylinder 41 and the tie rod mold 4 is the horizontal movement of the tie rod mold 4 stroke; the telescopic rod of the horizontal cylinder 41 is fixedly connected with the movable tie rod 44 ; the movable tie rod 44 is fixedly connected with the tie rod mold 4 through the connecting rod 45 .

[0061] A seat cloth assembling device of the present embodiment, the assembling method thereof is:

[0062] Step 1. First, insert the cloth cover hole 921 on one side of the seat cloth surface 92 into the side rod groove 911 of the side rod 91 of the seat cloth on one side of the seat cloth 9, and insert the cloth th...

Embodiment 3

[0070] The basic structure of a seat cloth assembling device of this embodiment is the same as that of Embodiment 2. The difference and improvement are that the number of connecting rods 45 is an even number, which is two in this embodiment. , to avoid pulling the fabric sideways.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com