Bridge supporting device, installation method thereof and bridge supporting system

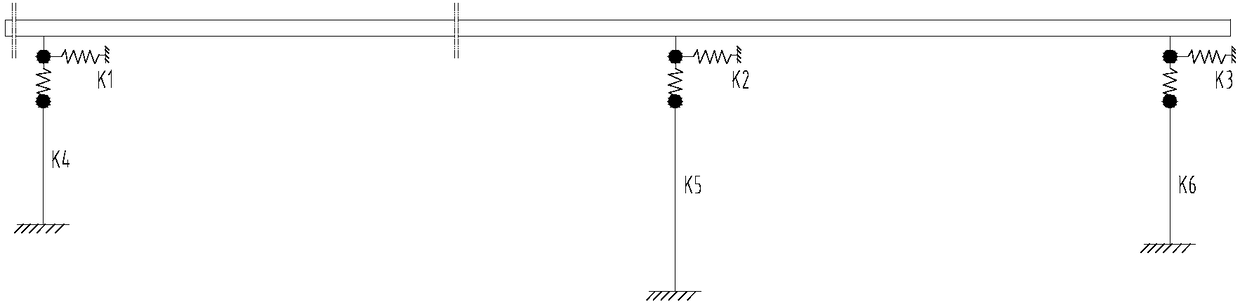

A technology of supporting device and installation method, applied in bridges, bridge parts, bridge construction and other directions, can solve problems such as insufficient vertical stiffness, reduced acceleration response, traffic vibration pollution, etc., to improve overall bearing capacity, reduce size, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

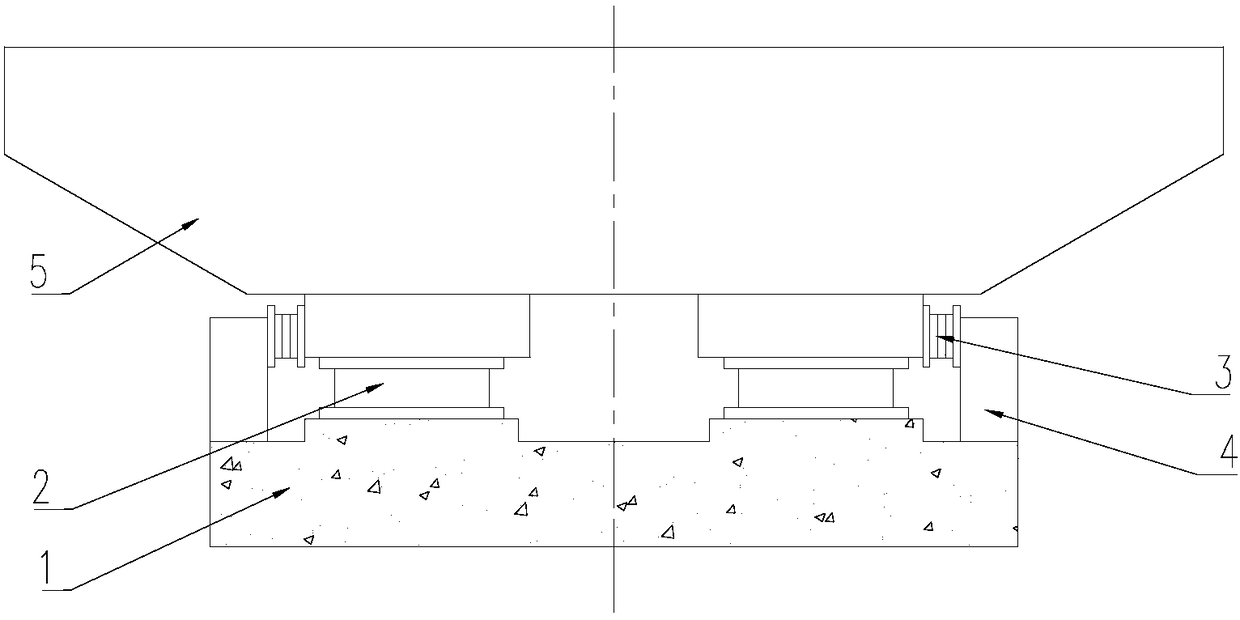

[0047] Such as figure 2 with image 3 As shown, the embodiment of the present invention provides a bridge support device installed between the bridge pier 1 and the superstructure 5 . The device includes: a supporting base 2 , a vibration-isolation bearing 3 and an installation base 4 .

[0048] Pier 1 is at the bottom of the bridge and provides support for the entire bridge. The piers 1 support the superstructure 5 of the bridge by means of supporting means.

[0049]The upper end of the bridge pier is provided with a boss for installing the support support 2, one end of the support support 2 is fixed on the above-mentioned boss, and the other end is fixedly connected with the superstructure 5 . The support base 2 is used to undertake conventional functions, and has the functions of bearing the vertical load, rotation and horizontal movement of the bridge superstructure. During an earthquake, the anti-pull function of the support device belongs to the vertical load, which...

Embodiment 2

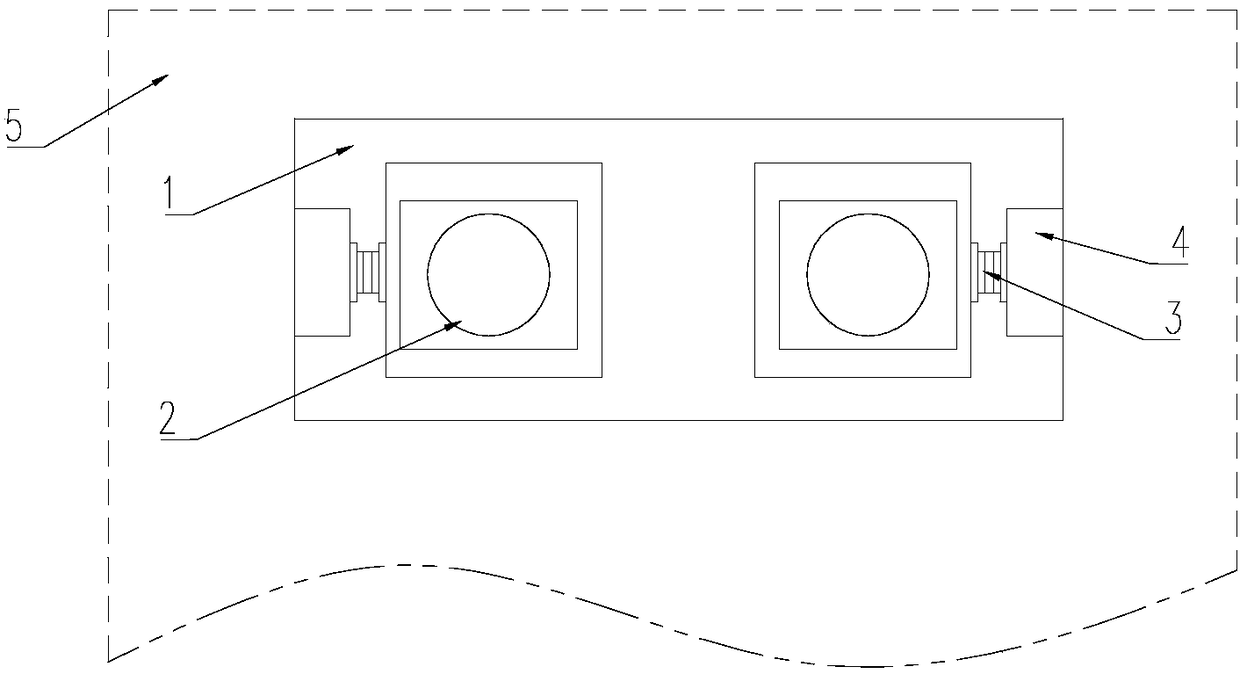

[0060] Such as Figure 5 with Image 6 As shown, the difference between embodiment 2 and embodiment 1 is that the mounting base 4 is fixed above the pier 1, the mounting base 4 is located in the middle of the two supporting bases 2, and the shock-isolation bearing 3 is fixed on the side of the mounting base 4 on the upper surface. Image 6 The dotted line in represents the superstructure of the bridge, and one end of the isolation bearing 3 is fixedly connected to the lower surface of the superstructure of the bridge.

[0061] Such a design can make the shock-isolation support 3 bear a small part of the vertical load, and minimize the vibration caused by traffic. However, the main function of the shock-isolation bearing 3 is still to bear horizontal loads.

[0062] On the other hand, an embodiment of the present invention provides a method for installing the above device, including steps:

[0063] 1. Install one end of the supporting support above the pier, and connect the...

Embodiment 3

[0067] Such as Figure 7 As shown, the embodiment of the present invention provides a bridge supporting device. The difference between this device and Embodiment 1 is that the mounting base 4 and the supporting base 2 are arranged at intervals, and the left and right sides of the mounting base 4 in the middle are equipped with shock-absorbing bearings 3 . Such a structure is more suitable for bridges located in high-earthquake areas.

[0068] On the other hand, an embodiment of the present invention provides a method for installing the above device, including steps:

[0069] 1. Install one end of the supporting support above the pier, and connect the other end to the superstructure.

[0070] 2. Install the mounting seat on the top of the bridge pier, and arrange the mounting seat and the supporting support at intervals.

[0071] 3. Install one end of the shock-isolation support on the side surface of the mounting base, and connect the other end to the upper structure.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com