Fluid control valve

A technology for controlling valves and fluids, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of small air flow, large pressure loss, and large volume of motor control, and achieve on-demand design, small flow loss, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

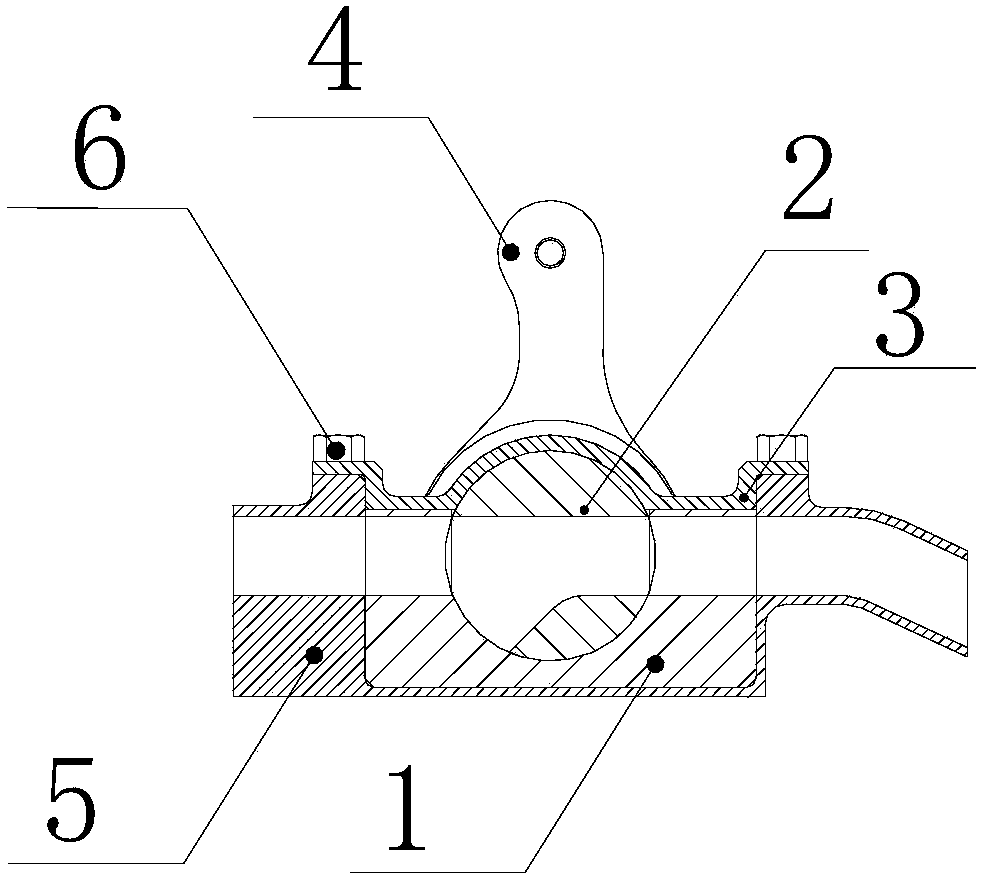

[0031] The structure of the fluid control valve designed by the invention is as figure 1 Shown. The fluid control valve component parts mainly include: a valve body (1); a valve core (2); a cover plate (3); a rocker arm (4); a base (5); a connecting screw (6). The valve body (1), the cover plate (3), and the base (5) are all fixed structures, and the valve core (2) and the rocker arm (4) are rotatable structures.

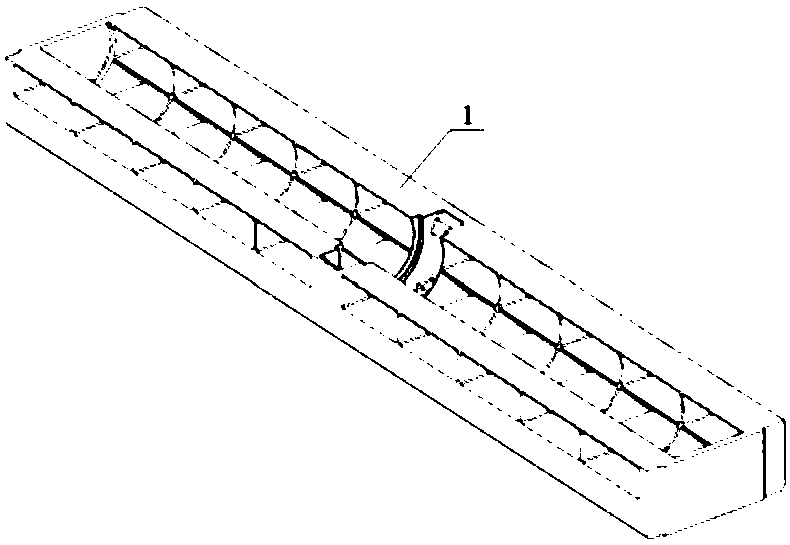

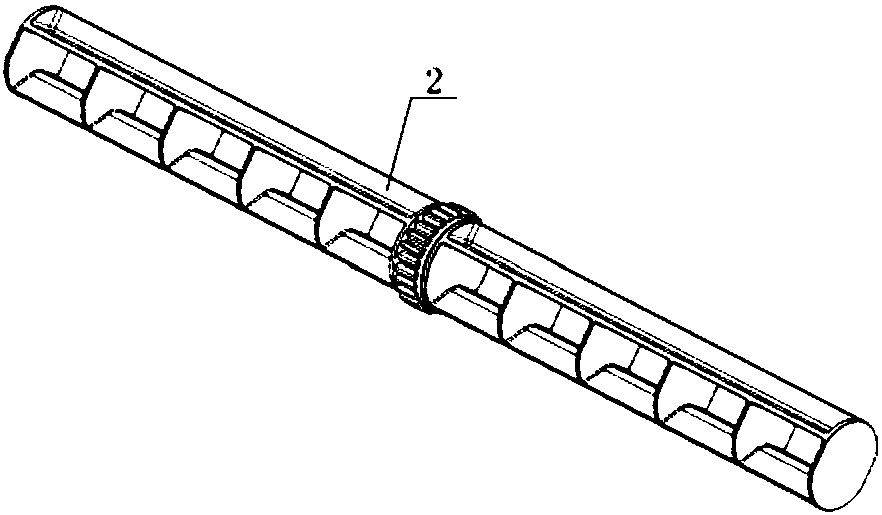

[0032] In the fluid control valve designed in the present invention, the valve body (1) is provided with a grid-shaped flow channel, such as figure 2 Shown. The basic shape of the outer surface of the valve core (2) is cylindrical, and the valve core (2) is also provided with a grid-like flow channel, such as image 3 As shown, the flow channel passes through the cylindrical surface of the valve core (2), and one end of the flow channel is provided with a guiding angle to reduce flow loss.

[0033] In the fluid control valve designed by the present invention, the rocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com