High-heat-insulation fire-proof steel section splicing and spot welding structure

A technology of steel profiles and plug-in points, applied in the direction of sheets/boards, building components, etc., can solve the problems that affect the normal operation and turnover of manufacturers, the heat resistance is not outstanding, and the heat conduction speed is slowed down, so as to achieve better heat insulation effect Excellent, reduce the contact area, slow down the effect of conduction velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

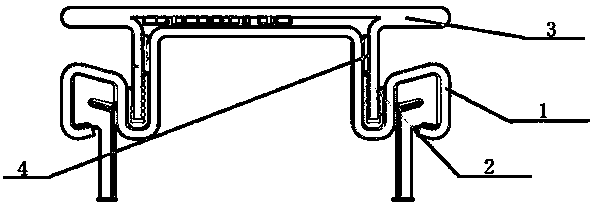

[0011] A plug-in spot welding structure for high heat-insulation and fireproof steel profiles, comprising: a connection device and a surface material connection device, wherein, the two ends of the connection device are respectively provided with bending grooves 1, and a square convex shape is used in the middle of the bending grooves at both ends. structure, the square raised structure and the back of the bending groove form a surface material connection tightening groove; the surface material connecting device adopts a connecting insert 2, and one end of the connecting insert 2 is connected to the required surface material 3 Integral molding structure, the other end of the connecting insert is inserted into the surface material connection tightening groove, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com