Broken stone railway ballast direct-shear testing apparatus

A direct shear tester and ballast technology, which can be applied to instruments, use a stable shear force to test material strength, scientific instruments, etc., can solve problems such as errors in direct shear test results, improve accuracy and reduce friction. strength, the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

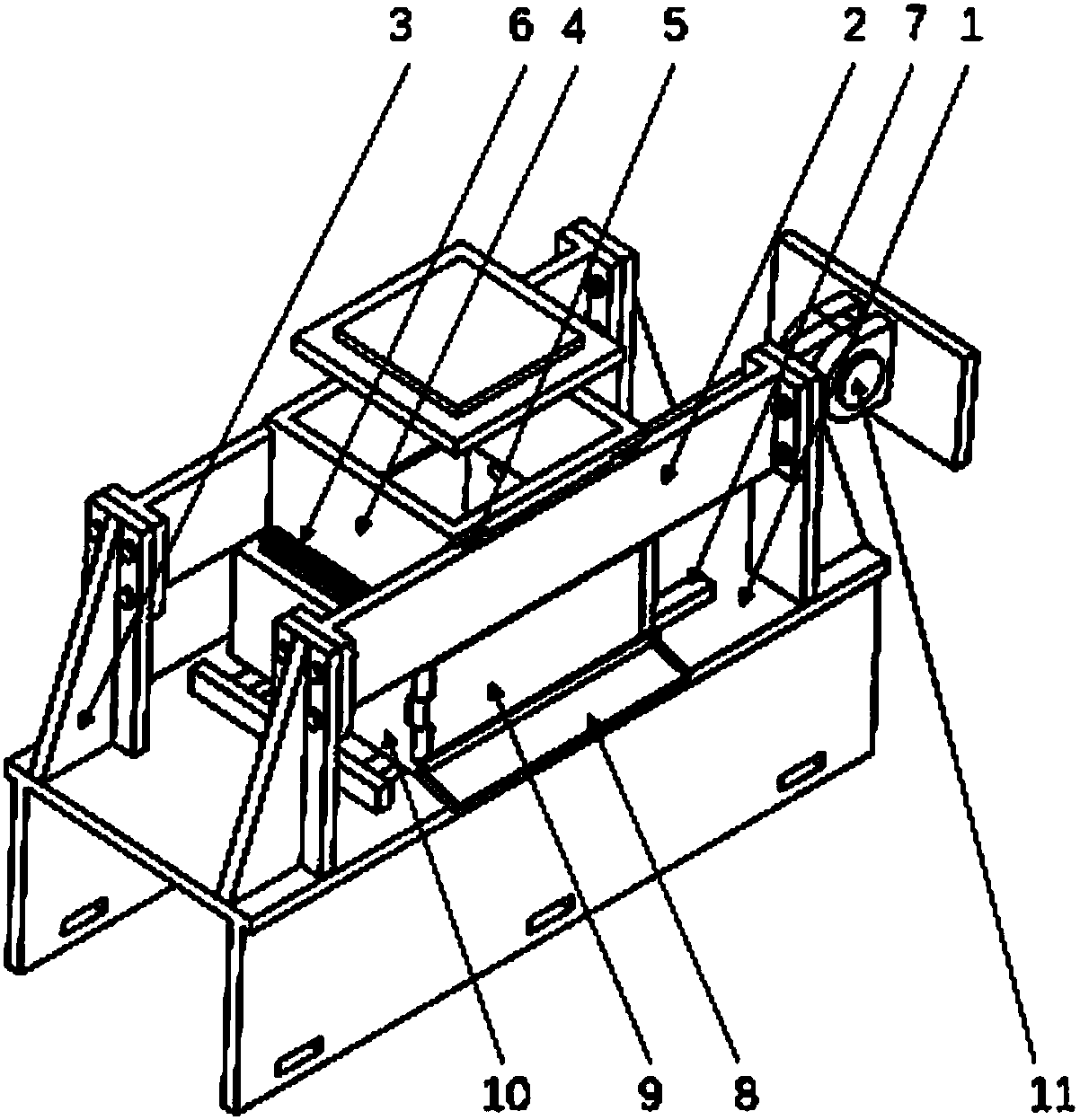

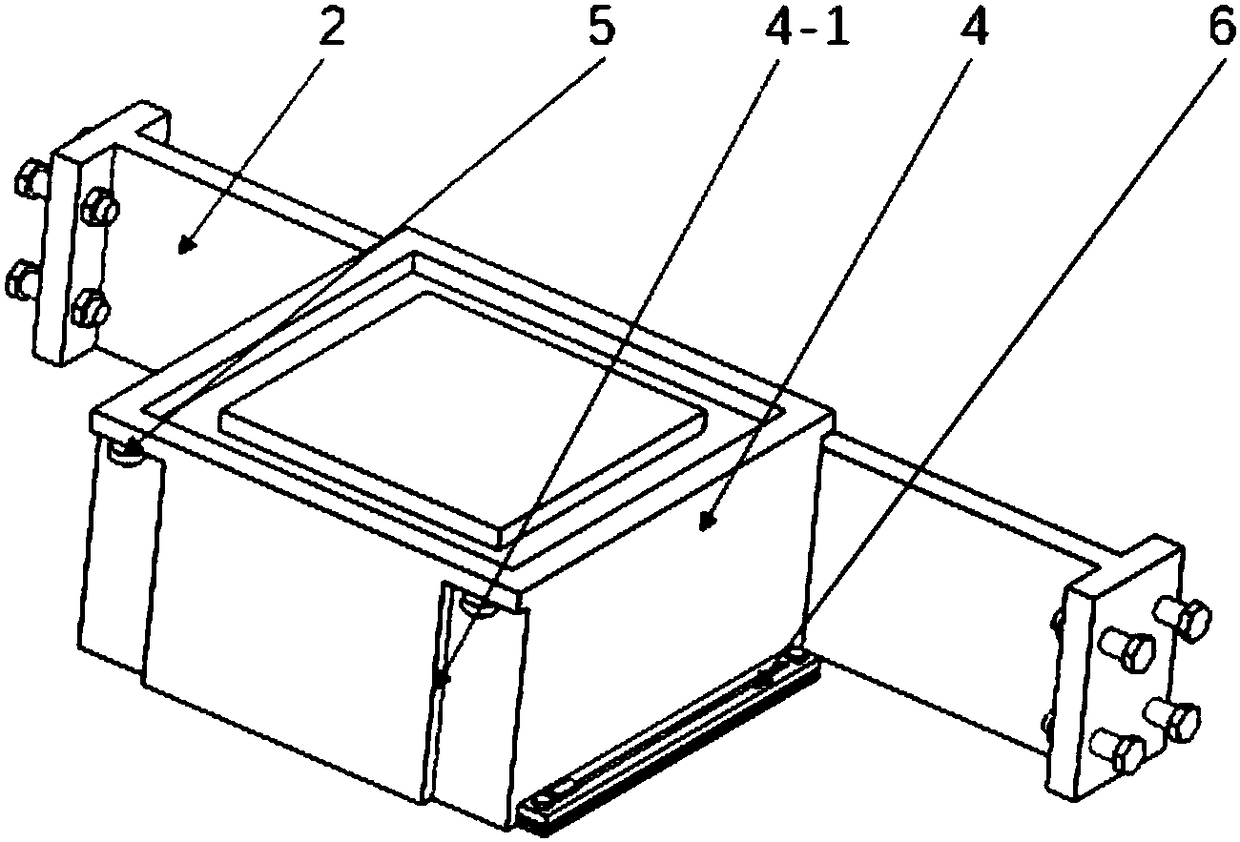

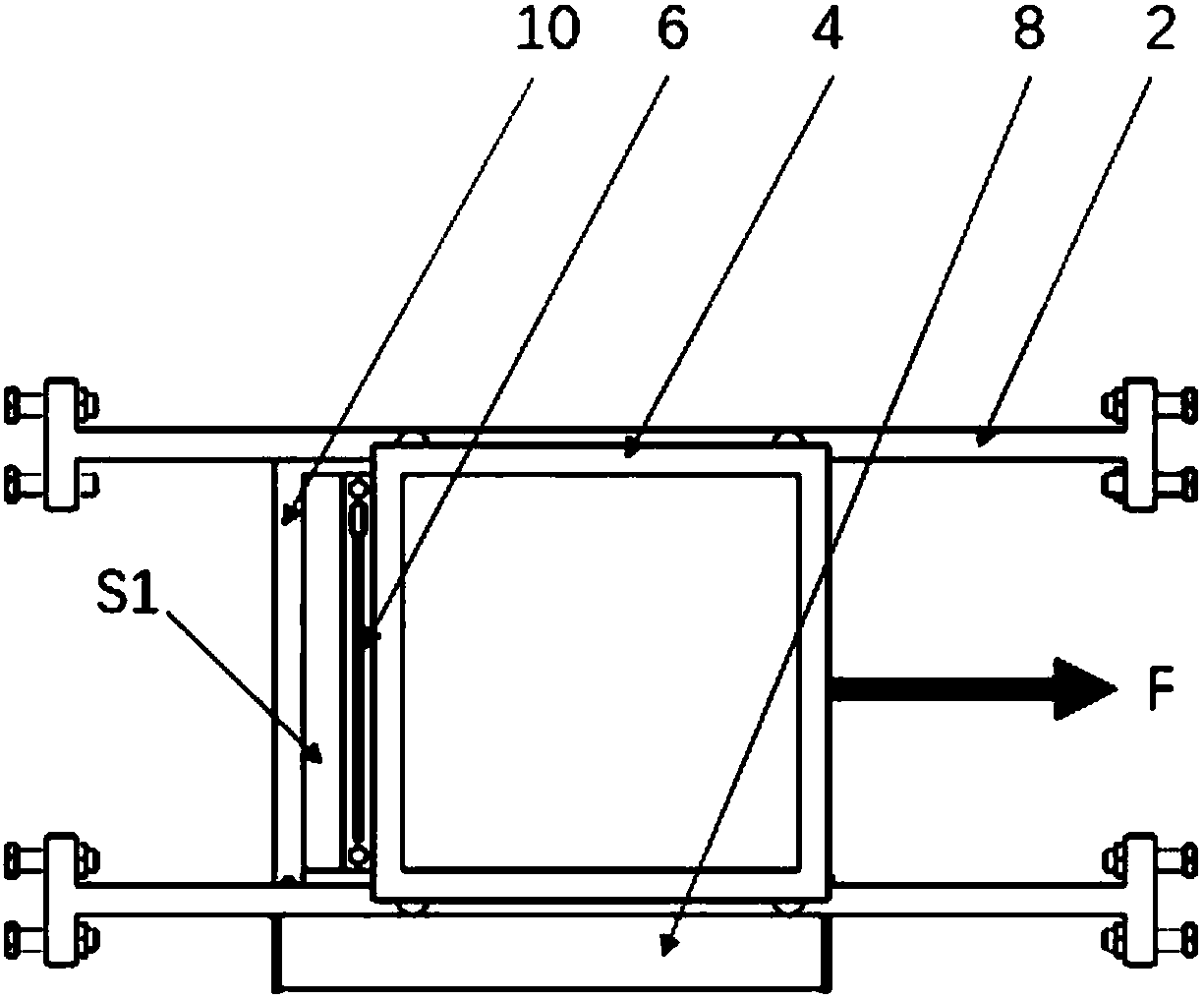

[0048] A gravel ballast direct shear tester, comprising a frame body 1, a lower box 10 is arranged on the frame body 1, an upper box 4 is arranged on the lower box 10, and the upper box 4 and the lower box 10 can be produce relative movement. To make relative movement between upper case 4 and lower case 10, upper case 4 can be fixed and lower case 10 can be moved, lower case 10 can also be fixed and upper case 4 can be moved. 10 can be moved, but the direction of movement is opposite. In addition, the length of the cavity of the lower case 10 is greater than the length of the cavity of the upper case 4, so that in a certain distance when the upper case 4 and the lower case 10 move relatively, the shear area formed between the upper case 4 and the lower case 10 does not It will not change continuously with the relative movement of the two on the horizontal plane.

Embodiment 2

[0050] On the basis of Embodiment 1, this embodiment preferably adopts the method of fixing the upper box 4 and moving the lower box 10 . That is, a guide rail 7 is arranged on the upper surface of the frame body 1, and the lower case 10 is installed on the frame body 1 by the guide rail 7, and one side of the lower case 10 is connected with a pulling member 11, so that the lower case 10 is lowered under the action of the pulling member 11. The box 10 is movable on the guide rail 7 along the track direction of the guide rail 7 .

Embodiment 3

[0052] On the basis of the second embodiment, the guide rail 7 adopts a linear bearing, and the friction force between the lower case 10 and the guide rail 7 can be reduced through the linear bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com